A practical guide to choosing assembly kits for detailed display models

Choosing the right assembly kit for a detailed display model involves more than picking an attractive box. Consider scale, materials, required tools, and the learning outcomes you want from the build. This short overview highlights key factors hobbyists and educators should weigh before committing to a kit.

Selecting an assembly kit for a detailed display model is a balance of personal goals, available time, and the skills you want to develop. Whether you seek a faithful miniature replica to add to a shelf or an educational project that improves spatial reasoning, knowing how scale, materials, and finishing options affect the final result helps you make informed decisions. This guide breaks down practical considerations for model selection, construction planning, crafting techniques, and long-term storage and display.

Model scale and miniature selection

Scale determines both the look of the finished model and the complexity of the assembly process. Smaller scales can yield striking display pieces but require finer tools and steady hands; larger scales often allow more detailed construction and easier painting. Consider the context of the display: a shelf of varied models benefits from consistent scales, while a standalone piece can be any size that suits the space.

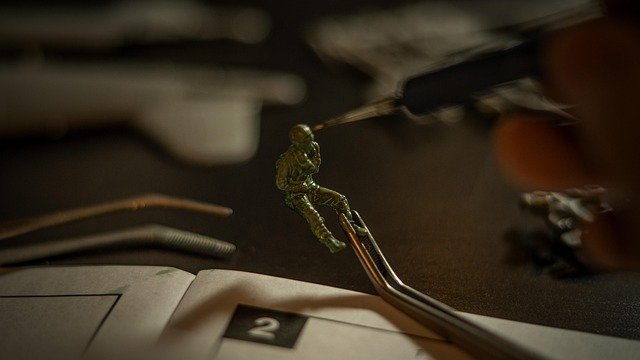

Look at the kit’s parts count and tolerance specifications: kits intended as miniatures often include many tiny components and precise mating surfaces. Check whether the kit includes pre-painted or pre-finished parts, as these reduce finishing work but limit customization.

Assembly and construction basics

Successful assembly relies on clear instructions, accurate parts labeling, and the right adhesives or fasteners for the materials involved. Instruction clarity varies widely; kits geared toward hobbyists usually include exploded diagrams and numbered steps that streamline the process. Beginners should favor kits with fewer subassemblies and larger, keyed joints.

Plan the sequence of construction to avoid access issues during painting or gluing. Dry-fit components before applying adhesive, and prepare a clean, well-lit workspace with small parts containers to prevent loss. Good organizational habits during assembly reduce rework and improve final alignment.

Materials and crafting techniques

Materials shape both the construction approach and the finishing options. Common materials include injection-molded plastic, laser-cut wood, metal, and cardstock. Plastic supports fine surface detail and is straightforward to glue and sand; wood offers texture and can be stained or varnished; metal parts add weight and durability but often require soldering or specialized adhesives.

Match crafting techniques to material: sanding and filler for plastic seams, careful clamping for wood joints, and solvent welds or epoxy for metal. Some kits mix materials; check compatibility of paints and adhesives. If sustainability or longevity is a concern, prefer materials with known archival properties and low off-gassing.

DIY finishing, painting, and display considerations

Finishing elevates a construction from a raw assembly to a display-quality piece. Plan masking, priming, and painting steps before final assembly when possible, since some details are easier to finish while subassemblies are open. Use appropriate primers for the chosen materials and select paints that adhere well and resist yellowing or flaking over time.

Consider mounting and display hardware early: integrated stands, bases, or internal support rods can be installed during construction to avoid later drilling. Weather and light exposure affect finishes, so choose sealants and varnishes that match the intended display environment.

Spatial skills, geometry, and educational value

Assembly kits can serve as practical tools for developing spatial reasoning and an intuitive grasp of geometry. Working with scaled parts teaches measurement conversion, proportions, and three-dimensional visualization. Kits with clear engineering logic—such as interlocking joints or modular subassemblies—reinforce concepts like tolerances and geometric fit.

For educators, choose kits with documented learning outcomes or stepwise complexity that supports progressive skill-building. Incorporating brief explanations of geometric relationships and measurement techniques can turn a crafting session into a focused learning opportunity.

Storage, organization, and long-term care

Organizing parts, instructions, and tools reduces frustration and protects fragile components. Use compartmentalized trays or labeled bags during assembly and retain the original packaging for long-term storage of unused parts. Humidity, temperature fluctuations, and direct sunlight can degrade materials and finishes; store models in stable conditions and consider dust covers or display cases for preservation.

Documenting the build process—photographs, notes on paints and adhesives—helps with future touch-ups and provides provenance if you rotate or loan pieces. For collections, cataloging scale, materials, and finish treatments supports consistent display decisions and maintenance planning.

Conclusion

Choosing an assembly kit for a detailed display model becomes easier when you match the kit’s scale, materials, and instruction quality to your skills and goals. Thoughtful planning around construction sequence, finishing methods, and storage will improve both the building experience and the longevity of the finished piece. With attention to these practical considerations, hobbyists and educators can select kits that satisfy aesthetic, educational, and preservation needs.