Achieving Accurate Cuts in Metalworking

Accurate cuts are fundamental to successful metalworking, influencing the quality, fit, and structural integrity of fabricated components. From large-scale industrial manufacturing to smaller workshop projects, the precision of metal cutting tools directly impacts the final product. Understanding the various cutting technologies and their applications is essential for professionals seeking to optimize their production processes and achieve consistent, high-quality results in material shaping.

What Types of Metal Cutting Tools are Used in Fabrication?

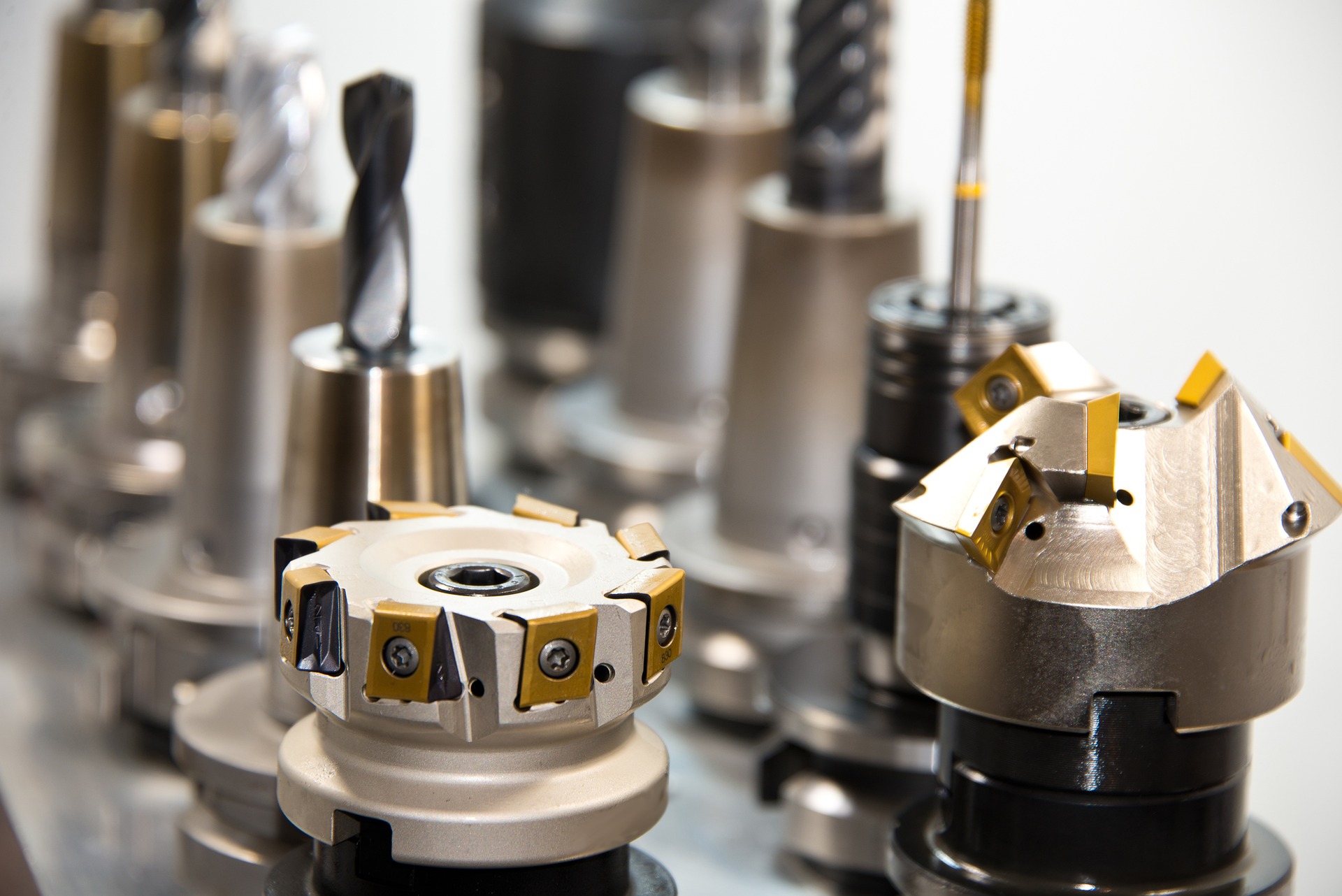

Metal cutting encompasses a wide array of tools and machinery, each designed for specific applications and material types. Manual tools like hacksaws and snips are suitable for light-duty tasks and thin materials. For more robust industrial and workshop needs, powered equipment becomes essential. This includes abrasive chop saws, band saws, and reciprocating saws for general cutting. Specialized equipment such as plasma cutters, laser cutters, and waterjet cutters offer advanced precision and efficiency for complex designs and various metal thicknesses, including steel and aluminum. The selection of the right tool depends heavily on the desired precision, material type, thickness, and production volume in manufacturing.

How Does Technology Enhance Metal Cutting Precision and Efficiency?

Modern technology has significantly transformed metal cutting, bringing unprecedented levels of precision and efficiency to the manufacturing process. Computer Numerical Control (CNC) systems are at the forefront, integrating with laser, plasma, and waterjet cutting equipment to automate complex cuts with minimal human intervention. This automation reduces errors, speeds up production, and ensures consistent quality across large batches of material. Advanced software allows for intricate designs to be translated directly into machine movements, optimizing material reduction and minimizing waste. The ongoing development in cutting technology focuses on faster processing speeds, improved cut quality, and enhanced safety features, contributing to overall production gains.

What are Key Considerations for Safety in Metalworking Operations?

Safety is a paramount concern in any metalworking environment, especially when operating powerful cutting machinery. Operators must wear appropriate Personal Protective Equipment (PPE), including safety glasses, hearing protection, gloves, and protective clothing, to guard against sparks, debris, and noise. Machines should always be maintained in good working order, with all safety guards and features functional. Proper training on equipment operation and emergency procedures is crucial to prevent accidents. Ensuring a clean and organized workshop also reduces hazards. Adhering to established safety protocols not only protects personnel but also contributes to a more efficient and productive work environment.

Understanding the Cost of Metal Cutting Equipment and Services

The investment in metal cutting equipment varies widely based on the type, technology, and scale of operation. Handheld tools are generally affordable, while industrial-grade machinery like CNC plasma or laser cutters represents a significant capital outlay. Service costs for outsourcing metal cutting also fluctuate depending on material, complexity, and volume. For instance, a basic angle grinder might cost under $100, whereas a professional-grade band saw could range from a few hundred to several thousand dollars. High-precision industrial equipment can easily run into tens or hundreds of thousands of dollars. These variations reflect the capabilities, speed, and precision each piece of equipment offers for different production and processing requirements.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Angle Grinder | DeWalt, Makita | $70 - $200 |

| Portable Band Saw | Milwaukee, Bosch | $300 - $800 |

| Plasma Cutter (Entry-Level) | Hobart, Hypertherm | $500 - $2,500 |

| CNC Plasma Cutting Service (per hour) | Local Fabrication Shops | $75 - $150 |

| Laser Cutting Service (per hour) | Specialized Industrial Firms | $100 - $300+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

How Can Workshops Enhance Material Processing and Production?

Enhancing material processing and production in a workshop involves a combination of strategic equipment selection, optimized workflow, and skilled personnel. Investing in high-quality, precise tools that match the specific materials and projects, such as those capable of cutting steel and aluminum with ease, is a foundational step. Implementing lean manufacturing principles can reduce waste and improve efficiency by streamlining the movement of materials and components. Regular maintenance of machinery ensures consistent performance and extends equipment lifespan. Furthermore, continuous training for operators on new technologies and best practices can significantly boost overall production capacity and the quality of finished products, contributing to a more robust manufacturing output.

Achieving accurate cuts in metalworking is a multifaceted endeavor that relies on the right tools, advanced technology, and a strong commitment to safety. From basic hand tools to sophisticated CNC machinery, each piece of equipment plays a role in the precise shaping and reduction of materials. Continuous innovation in cutting technology promises further advancements in efficiency and precision, benefiting workshops and industrial operations worldwide. By understanding these elements, professionals can ensure high-quality fabrication and optimal production outcomes.