Budgeting routine repairs to extend appliance service life

Routine repair budgeting helps homeowners and building managers schedule small fixes before they become large replacements. A planned approach to upkeep balances inspection, minor parts, and labor expenses while improving runtime, safety, and energy performance across appliances.

Routine care and planned repairs can significantly extend the service life of household and commercial appliances. Rather than reacting to sudden failures, a budgeted repair strategy prioritizes periodic inspection, small parts replacement, and corrective work that preserves combustion efficiency, aerodynamic performance, and overall component integrity. This article explains practical budgeting steps and maintenance actions—covering filters, condensate management, ducts, gaskets, thermostats, airflow, moisture control, valves, lubrication, diagnostics, runtime monitoring, energy considerations, and combustion components—to help you plan predictable spending and avoid costly emergency replacements.

Filters and airflow

Regularly replacing or cleaning filters is one of the most cost-effective repairs to maintain airflow and reduce wear. Clogged filters restrict circulation, forcing fans and compressors to run longer and increasing runtime and energy use. When budgeting, allocate funds for periodic filter purchases and occasional professional cleaning if filters are reusable. Monitoring static pressure or noting reduced airflow during diagnostics can indicate filter-related losses; addressing these promptly reduces strain on motors and extends the life of downstream components.

Condensate, ducts, and moisture

Condensate lines, ductwork, and moisture control are common failure points that are inexpensive to remedy when caught early. Blocked condensate drains cause backups and corrosion, while leaky or damaged ducts reduce system efficiency and can introduce moisture into cavities that degrades gaskets and insulation. Budget for seasonal duct inspections, condensate line clearing, and minor repairs to seals. Preventing moisture-related problems avoids mold remediation and premature replacement of sensitive parts.

Gaskets, valves, and lubrication

Small seals and moving parts like gaskets and valves often determine whether a system operates reliably. Gaskets that harden or crack lead to pressure losses or combustion air leaks; valves that stick or leak affect safety and performance. Regular lubrication of bearings and linkage prevents excess friction and overheating. When setting a repair budget, include a line item for consumable seals, valve servicing, and periodic lubrication supplies or technician labor. These items are relatively low cost but have outsized impact on longevity.

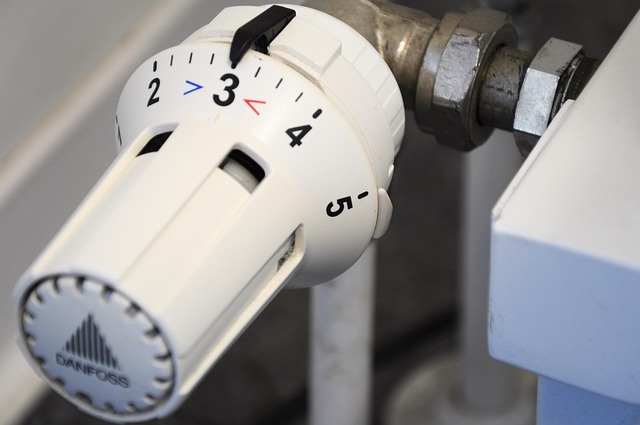

Thermostat, diagnostics, and runtime

Thermostat accuracy and routine diagnostics help control runtime and reveal underlying problems before they escalate. A miscalibrated thermostat causes short-cycling or extended cycles, both of which increase wear. Investing in periodic diagnostic checks—either DIY checks of setpoints and runtime logs or professional diagnostic visits—lets you spot abnormal combustion behavior, unusual runtime patterns, or control faults. Allocate part of your budget for replacement thermostats or smart controls when diagnostics show recurring issues tied to control failures.

Inspection, safety, and combustion

Scheduled inspections that include combustion analysis and safety checks protect both equipment and occupants. Combustion inefficiency raises energy use and deposits that accelerate component wear; safety elements such as flame sensors, vents, and pressure switches must be verified regularly. Budgeting for annual or biannual safety inspections ensures these items are tested and repaired as needed. Prioritizing safety-related repairs reduces risk and prevents damage that would shorten the appliance service life substantially.

Energy, moisture control, and performance planning

When budgeting routine repairs, consider the energy consequences of deferred maintenance. Components operating inefficiently—blocked airflow, degraded gaskets, or poor combustion—consume more energy and incur higher operating costs. Include contingency funds for unexpected valve replacements, condensate pump repairs, or minor duct sealing. Track performance metrics like runtime and energy use to justify repair spending: small investments in lubrication or filter replacement often pay back through lower utility bills and reduced stress on major components.

Conclusion A structured repair budget ties together inspection, minor parts replacement, and targeted service to keep appliances running longer and safer. Focusing on filters, condensate and moisture control, ducts and gaskets, valve and lubrication upkeep, thermostat accuracy, diagnostics, runtime monitoring, energy impacts, and combustion health makes repair spending predictable and efficient. By planning small repairs and periodic inspections, you reduce the likelihood of premature failure and achieve steadier performance over the appliance lifecycle.