Building Materials in Construction: Concrete, Wood, Steel

Choosing the right building materials affects durability, cost, environmental impact, and the final performance of a structure. This article explains common materials used in construction, focusing on concrete, wood, and steel, and how they compare across typical applications. The goal is to give a clear, practical overview that helps readers understand material properties, common uses, and considerations for selection.

Building materials: common categories

Building materials cover a wide range of manufactured and natural products used in construction, including masonry, aggregates, metals, timber, polymers, and composites. Each category has typical roles: structural support, insulation, finishes, or moisture barriers. Selection depends on load requirements, local climate, availability, and regulatory standards. For projects in your area, consider how local services, supply chains, and code requirements influence which materials are most practical and readily available.

How construction uses different materials

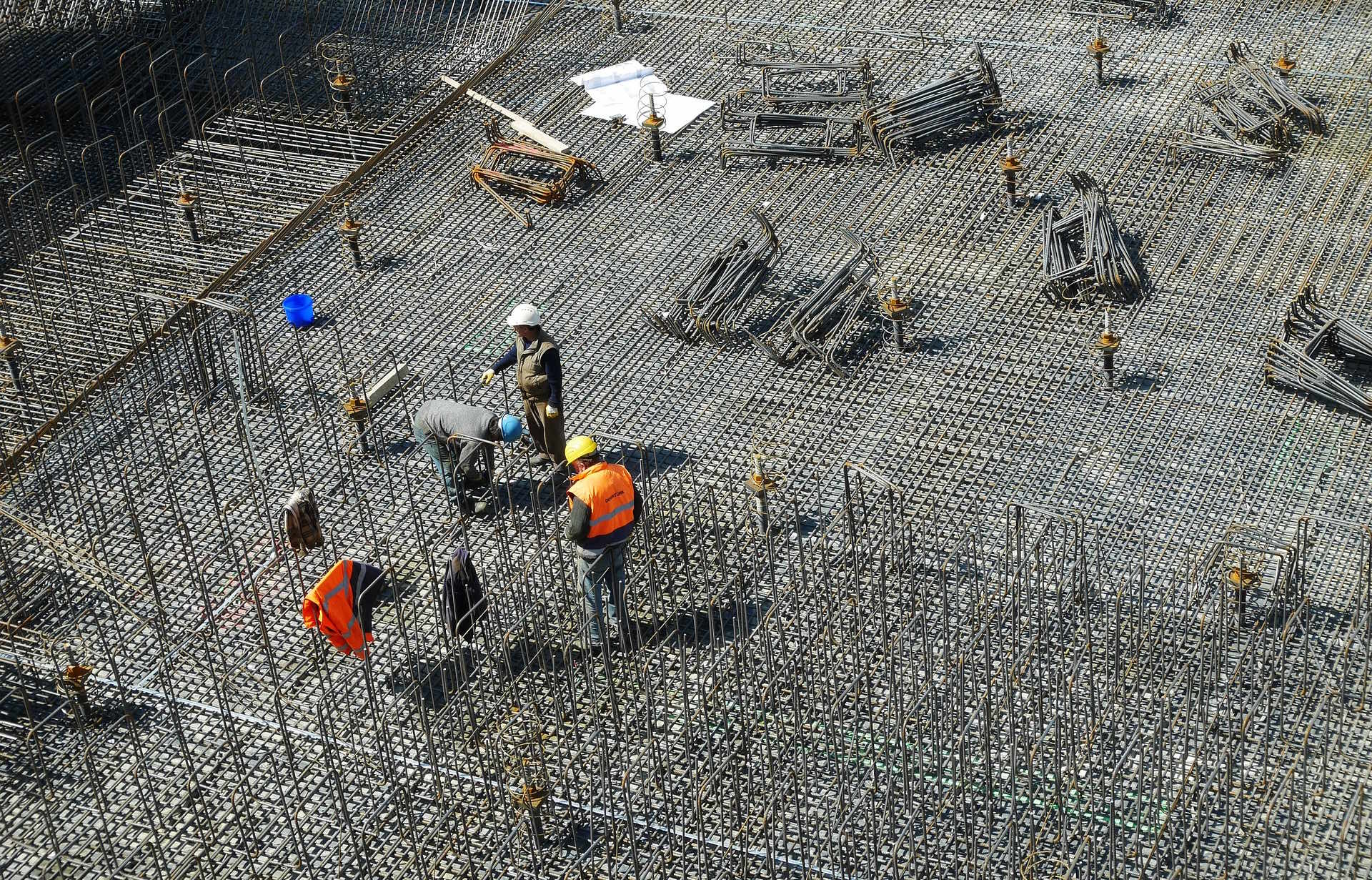

In construction practice, materials are combined to meet structural and non-structural needs. Foundations typically rely on concrete and reinforced steel; frames may use steel, engineered wood, or masonry; and finishes use plaster, siding, or cladding. Contractors and designers balance performance, buildability, and maintenance. For example, using prefabricated elements can reduce onsite labor but requires early coordination with suppliers and local services. Environmental requirements and lifecycle analysis are increasingly important in material selection for sustainable construction.

Concrete: properties and typical uses

Concrete is a composite of cement, aggregates, water, and often admixtures; it is prized for compressive strength and versatility. Typical uses include foundations, slabs, columns, beams, and precast elements. Concrete performs well under compression but needs reinforcement (usually steel rebar) for tensile loads. Variants such as high-strength concrete, lightweight mixes, and fiber-reinforced concrete address specific performance needs. Durability considerations include freeze-thaw cycles, exposure to chemicals, and proper curing—design choices and detailing influence long-term performance.

Wood: types, benefits, limitations

Wood remains widely used for framing, finishes, and decorative elements because of its workability, renewability, and thermal performance. Common building-grade species and engineered products include softwoods for framing and cross-laminated timber (CLT) or glulam for larger structural members. Benefits of wood include lighter weight, aesthetic warmth, and carbon sequestration potential when sourced responsibly. Limitations include vulnerability to moisture, pests, and fire; these are managed through treatment, detailing, and compliance with fire codes. Sourcing from certified suppliers can improve sustainability credentials.

Steel: role in modern construction

Steel provides high strength-to-weight ratios, predictable behavior, and speed of assembly, making it a staple for structural frames, reinforcements, and long-span systems. Typical steel products include structural beams, columns, decking, and reinforcement bars used with concrete. Steel is recyclable and allows for slender profiles and large open interior spaces. Corrosion protection, welding quality, and connections are critical design considerations. The choice between steel and alternatives often depends on project scale, erection logistics, and coordination with fabricators and local services.

Conclusion

Understanding the basic properties and common uses of concrete, wood, and steel helps guide material choices in construction. Each material offers distinct advantages and trade-offs: concrete for mass and compressive strength, wood for versatility and embodied carbon benefits, and steel for strength and speed. Effective decisions consider structural needs, environmental context, maintenance requirements, and the availability of local services and supply chains to ensure the selected materials suit the intended performance and lifecycle expectations.