CNC Machines: A Practical Guide to Modern Machining

Computer Numerical Control (CNC) machines are the backbone of many modern manufacturing operations, combining software, motors, and tooling to produce precise parts repeatedly. From prototyping to mass production, CNC technology speeds up workflows and reduces manual error, making it essential equipment for industries that demand consistency and accuracy.

What is a CNC machine?

A CNC machine is an automated device controlled by computer programs that execute pre-written code to move tools and workpieces along multiple axes. The code—often generated from CAD/CAM software—tells the spindle, motors, and tool-changer exactly where to cut, drill, mill, or turn material. Common CNC types include mills, lathes, routers, and plasma cutter tables adapted for computer control.

CNC machines improve repeatability and allow complex geometries that are difficult or impossible by hand. They support a wide variety of materials—plastics, metals, composites, and wood—and are judged by metrics like axis count, spindle speed, feed rates, and positional accuracy. For many operations, CNC reduces cycle time and improves part quality.

How does manufacturing use CNC machines?

In manufacturing, CNC machines are used for everything from single-part prototyping to high-volume production runs. They enable tight tolerances and consistent interchangeability of parts, which is critical for sectors such as aerospace, automotive, medical devices, and electronics. Manufacturers integrate CNC into production cells alongside inspection equipment, robotics, and conveyors for automated workflows.

CNC also supports flexible manufacturing: quickly reprogramming machines to make different parts lowers setup costs and shortens product development cycles. When combined with CAM optimization and advanced toolpaths, CNC systems can maximize material usage and minimize machining time, improving overall shop efficiency.

What is a plasma cutter and how is it used?

A plasma cutter uses ionized gas at high temperature to cut electrically conductive materials like steel or aluminum. When paired with CNC control, a plasma cutter becomes a CNC plasma table that follows programmed paths to cut intricate shapes with speed and economy—useful for structural parts, brackets, and sheet metal fabrication.

CNC plasma systems are valued for their cutting speed and ability to handle thicker metals economically compared with some laser options. Their limitations include a wider kerf and less fine edge quality on thin stainless steels compared to laser cutting, so selection depends on material, tolerance, and finish requirements. Proper ventilation and safety controls are essential when using plasma equipment.

How does CNC change traditional machining?

CNC redefines machining by shifting emphasis from manual skill to digital process control. Traditional manual machining relies on operator adjustments and experience; CNC translates design files directly into machine movement, enabling complex contours, repeatable pocketing, and intricate 3D surfaces. Toolpath strategies like trochoidal milling, adaptive clearing, and multi-axis simultaneous machining expand what’s feasible.

CNC also tightens integration with inspection: coordinate measuring machines (CMMs) and in-process probing can verify dimensions and feed back corrections, reducing scrap. Skilled machinists still play a key role in fixture design, tool selection, and process optimization, so successful CNC operations blend human expertise with automated precision.

What equipment and support should you consider?

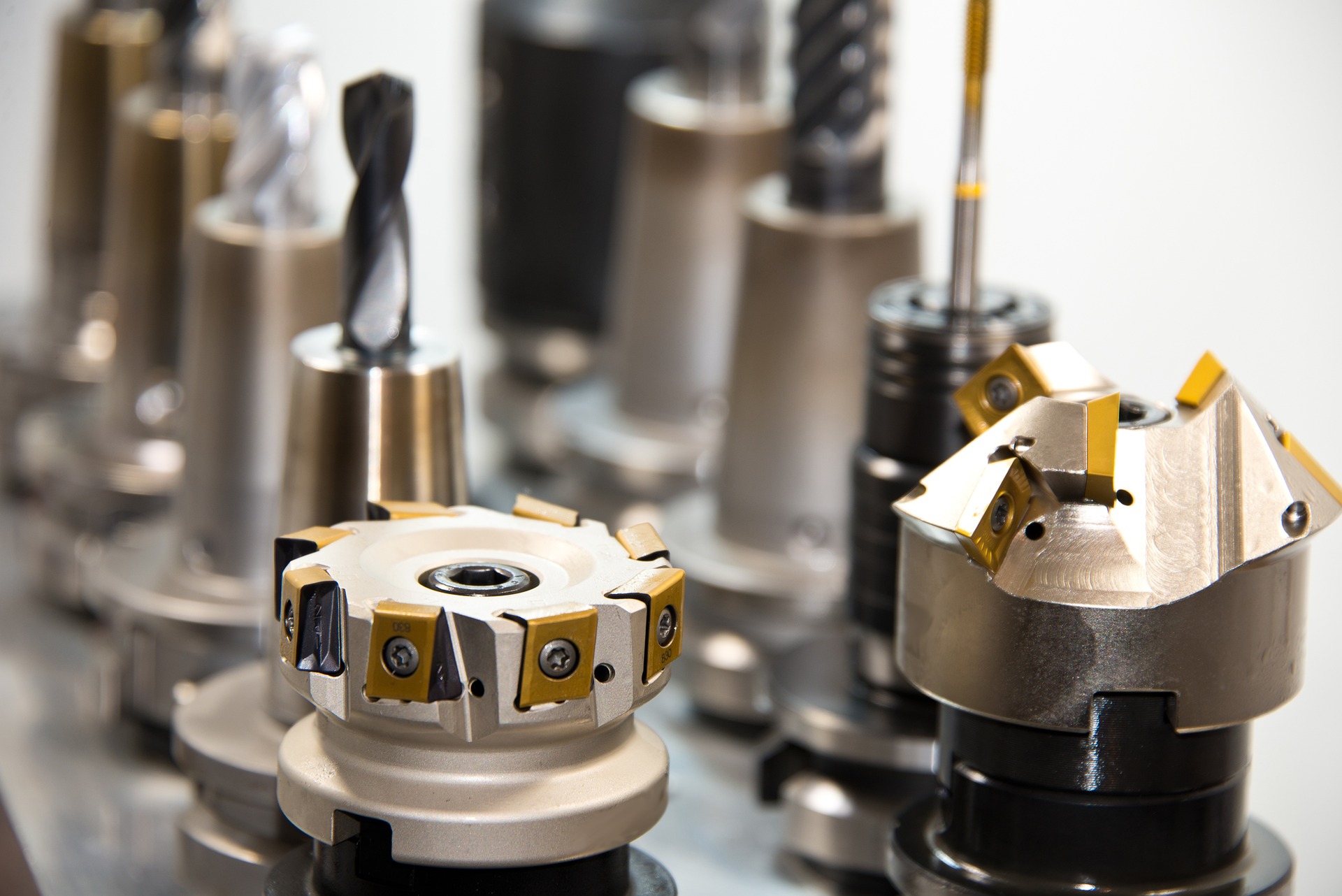

Selecting CNC equipment means matching machine type and features to the parts, materials, and production volumes you expect. Core considerations include axis count (3, 4, or 5), spindle power, tool changer capacity, coolant systems, and controller compatibility with your CAD/CAM stack. Peripheral equipment—such as chucking systems, vacuum tables, dust or fume extraction, and tool presetter devices—affects productivity and safety.

Beyond hardware, factor in software, training, maintenance plans, and local services for repairs or retrofits. Many shops build relationships with equipment vendors or local services for preventive maintenance, spare parts, and controller updates. Investing in operator training and documented procedures yields better uptime and more consistent part quality.

Conclusion

CNC machines are versatile tools that have reshaped modern machining and manufacturing by enabling precision, repeatability, and flexible production. From CNC-enabled plasma cutter tables to multi-axis mills and lathes, choosing the right combination of machines, tooling, and support determines how well a shop converts designs into reliable parts. Thoughtful investment in equipment, software, and skilled personnel produces measurable gains in quality and throughput.