Cost Factors: How Production Choices Influence Card Pricing

Understanding why one greeting card costs more than another helps buyers and small sellers make informed decisions. Production choices such as paper stock, printing method, customization level, and fulfillment all shape the final price. This article breaks down those factors and offers a practical view of how they affect per-card and overall order costs.

Production choices determine much of a greeting card’s final price, from the raw paper to how it gets delivered. Makers and buyers should consider how design complexity, printing technique, paper weight, envelopes, packaging, and shipping add to costs. This article explains common factors in accessible language and shows how those choices map to pricing for both physical and digital greeting cards.

How does customization and personalization affect pricing?

Customization and personalization add labor, setup, and sometimes digital tooling costs. Simple personalization—adding a name or short message—may be priced as a small per-card fee or bundled into a print-on-demand service. More elaborate customization, such as bespoke artwork, custom typefaces, hand-lettering, or imprinting, can require extra design time or plate setup for offset printing, increasing unit cost. Variable-data printing (personalizing each card with unique text or images) is more expensive than running identical copies, though online platforms often offer tiered pricing that reduces unit cost as volume rises.

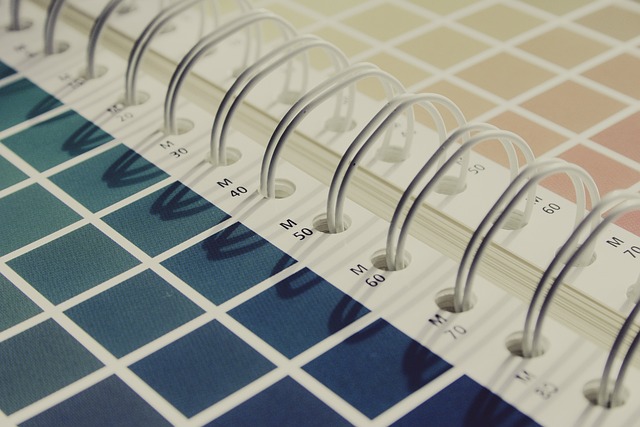

What role does paper choice play in quality and pricing?

Paper stock influences tactile quality and price. Heavier, textured, or specialty papers—linen, recycled cotton, seeded paper—cost more per sheet and may require different handling in print runs. Coated papers achieve richer colors with certain printing methods but can raise costs; uncoated stocks are usually cheaper and better suited for handwritten notes. Paper choices also affect envelopes and packaging; thicker cards often need sturdier envelopes and protective mailers, adding to packaging and shipping weight.

How do printing methods change production costs?

Different printing methods suit different runs and designs. Digital printing has lower setup costs for short runs and supports personalization, but per-unit costs can be higher at scale. Offset printing lowers per-unit price for larger runs but has setup and plate fees. Letterpress, foil stamping, embossing, and die-cutting are specialty finishes that add significant per-unit cost due to extra time and equipment. Print method decisions balance desired finish, run size, and budget, with quality and design constraints guiding the trade-offs.

How do ecards and digital design impact pricing and accessibility?

Ecards remove many material and shipping costs, offering lower marginal cost per send and instant delivery. Design and accessibility remain important: creating accessible digital greetings (clear text, alt text for images, readable color contrast, mobile optimization) increases development time but expands reach. Licensing images, animation, or interactivity can add upfront costs. For organizations prioritizing sustainability or accessibility, ecards can be a cost-efficient option, though some recipients prefer physical cards for their tactile and keepsake value.

How do sustainability, packaging, and envelopes affect final cost?

Sustainable choices—recycled paper, FSC-certified stock, compostable packaging—typically add to material costs but may appeal to eco-conscious buyers and justify higher price points. Envelopes, inner sleeves, protective mailers, and branded packaging increase both material and fulfillment complexity. Bulk-buying envelopes and eco-friendly packaging can reduce unit costs over time, but small producers often face higher per-unit packaging expenses until they scale. Packaging design also impacts perceived value and can influence retail or online pricing strategies.

What are real-world pricing examples and fulfillment/shipping costs?

Below are representative providers and common product examples with estimated cost ranges. These are intended as benchmarks; actual prices depend on options like paper, finishes, and shipping.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Custom folded cards (pack of 25, digital print, basic paper) | Vistaprint | $20–$50 |

| Premium single cards (per card, premium paper, small-run) | Moo | $1.50–$4.00 each |

| Designed cards (per card, single purchase, premium design) | Minted | $2.50–$7.00 each |

| Custom printed cards (per card, variable options) | Zazzle | $1.00–$3.50 each |

| Photo and folded cards (pack, includes envelopes, bulk options) | Shutterfly | $15–$40 per pack |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Real-world cost and pricing insights: many providers offer discounts for larger quantities, and fulfillment options (batch shipping vs. direct-to-recipient) alter total costs. Print-on-demand services minimize inventory costs but raise per-unit prices, while bulk offset printing reduces unit price but requires larger upfront expenditure. Additional services—address printing, handwritten-simulated fonts, gift packaging, or rush production—can add per-order fees. Shipping costs vary by weight, insurance, destination, and carrier; international shipping and tracked services increase the total invoice above base print prices. Always compare sample proofs and ask providers about hidden fees such as file setup, color correction, or returns handling.

Conclusion Production choices from customization and paper to printing method, sustainability, packaging, and fulfillment shape the cost and perceived value of greeting cards. Balancing quality, accessibility, and pricing depends on run size, audience expectations, and whether digital or physical formats are preferable. Understanding these factors helps buyers and creators estimate budgets and choose production pathways that match their goals.