Crafting Advanced Circuitry for Global Innovation

The intricate world of modern technology relies heavily on foundational components, among which circuit boards stand out as critical. These complex assemblies are the silent workhorses powering everything from consumer gadgets to sophisticated industrial machinery, medical devices, and aerospace systems. The individuals responsible for bringing these vital elements to life play a crucial role in advancing global innovation, ensuring that electronic devices function as intended, meet rigorous performance standards, and contribute to the seamless operation of contemporary applications across various sectors. Their work is a testament to precision and technical skill in the ever-evolving landscape of electronics.

Understanding Electronics Manufacturing and Assembly

The journey of an electronic device, from initial concept to end-user consumption, involves numerous intricate stages, with manufacturing and assembly standing as pivotal phases. Electronics production encompasses a broad spectrum of activities, but at its core is the precise arrangement and interconnection of various components onto a foundational circuit board. This comprehensive production process demands an exceptionally meticulous attention to detail, as even the slightest misalignment or imperfection can significantly impact the functionality, reliability, and lifespan of the final product. The assembly phase is where diverse raw materials and discrete parts are systematically brought together, transforming them into fully functional electronic units that are ready for integration into larger, more complex systems, driving forward the capabilities of modern technology.

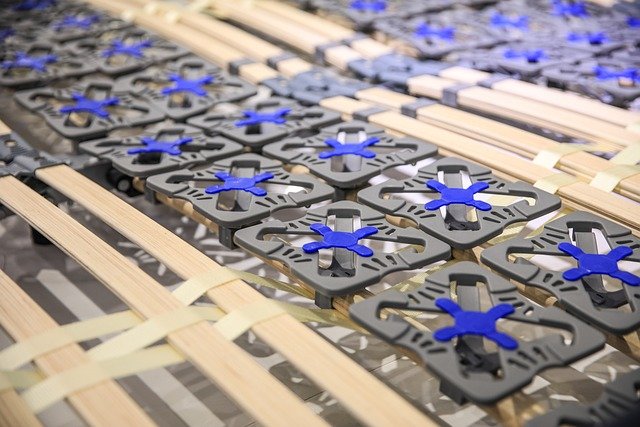

Key Components and Circuit Board Fabrication

Central to the operation of virtually any electronic device is the printed circuit board (PCB), which serves as a fundamental platform providing both mechanical support and crucial electrical connections for all electronic components. These components, which range widely from passive elements like resistors and capacitors to active integrated circuits and microcontrollers, are carefully placed and then soldered onto the designated areas of the PCB. The initial fabrication of these boards itself involves highly specialized processes, including the precise etching of conductive pathways and the accurate drilling of holes for component leads. A comprehensive understanding of the function, characteristics, and intricate interactions of these diverse components is absolutely essential for effective and reliable assembly, contributing significantly to the overall reliability and superior performance of advanced electronic technology.

The Role of Precision and Quality in Production

Within the exacting realm of electronics production, precision is far more than a mere preference; it is an absolute and fundamental requirement that underpins the entire manufacturing process. The increasingly miniature scale of modern components and intricate circuits necessitates extreme accuracy in every single step of the assembly process. Maintaining exceptionally high quality standards is paramount to actively prevent defects, ensure the long-term longevity of products, and consistently meet stringent industry specifications and regulatory compliance. This unwavering focus on both precision and quality extends comprehensively to visual inspections, rigorous functional testing, and strict adherence to established manufacturing protocols, all of which are meticulously designed to deliver reliable electronic devices that perform consistently and flawlessly across a wide array of demanding applications within the global industry.

Surface Mount Technology (SMT) and Advanced Techniques

Modern circuit board assembly extensively utilizes and relies upon Surface Mount Technology (SMT), a highly efficient method where electronic components are mounted directly onto the surface of the PCB, rather than being inserted through holes. This innovative technique allows for significantly higher component density, which in turn leads to improved electrical performance, reduced manufacturing costs, and the creation of much more compact and lightweight designs compared to older, traditional through-hole technology. SMT processes typically involve highly automated pick-and-place machines that precisely position tiny components with incredible accuracy, followed by a controlled reflow soldering process. The proficient application of such advanced manufacturing techniques requires specialized knowledge, continuous training, and sophisticated equipment, clearly highlighting the continuous evolution within the electronics industry and the constant demand for highly skilled technician roles capable of operating and maintaining these complex systems.

The Circuit Board Assembly Technician’s Contribution to Industry

Individuals working diligently as circuit board assembly technicians are absolutely vital contributors to the success and advancement of the broader electronics industry. Their comprehensive expertise spans various critical aspects of modern manufacturing, ranging from accurately interpreting complex technical diagrams and operating sophisticated automated assembly machinery to performing detailed visual inspections, conducting functional testing, and effectively troubleshooting potential issues. These dedicated professionals ensure that each PCB is assembled according to exact, precise specifications, thereby playing a direct and indispensable role in determining the overall quality, reliability, and functionality of electronic products worldwide. Their essential work underpins and supports numerous critical sectors, including telecommunications, automotive, medical devices, defense, and consumer electronics, fundamentally driving the advancement of modern technology through diligent application of engineering principles in the production environment.

The meticulous process of circuit board assembly remains a fundamental cornerstone of global technological progress and innovation. From the initial precise fabrication of PCBs to the careful placement of minute components using advanced techniques like SMT, every single stage requires a sophisticated blend of specialized skill, unwavering attention to detail, and a deep understanding of electronics engineering principles. The unwavering dedication to quality and precision throughout the entire manufacturing process ensures the reliability, performance, and safety of the countless electronic devices that permeate and shape our modern world, unequivocally highlighting the ongoing critical importance of this specialized industry role.