Driving Innovation Through Electronic Structure Creation

The intricate world of modern electronics relies heavily on the skilled hands and keen eyes of circuit board assemblers. These professionals are fundamental to bringing technological innovations to life, transforming raw materials and discrete components into functional electronic devices. Their work ensures the precise integration of countless tiny parts, forming the backbone of everything from consumer gadgets to advanced industrial machinery, thereby enabling the digital age.

The Core Role in Electronics Manufacturing

Circuit board assemblers play a pivotal role in the electronics industry, serving as the essential link between design and a tangible product. Their contribution is central to the entire manufacturing pipeline, where they are responsible for the physical construction of printed circuit boards (PCBs). These boards are the foundational elements for nearly all modern hardware and devices, from smartphones and computers to sophisticated medical equipment and automotive electronics systems. Through careful production processes, assemblers ensure that the conceptual designs of engineers are accurately translated into functional electronic structures.

Their work is critical in large-scale production environments, where efficiency and accuracy directly impact the output of electronic goods. By meticulously assembling PCBs, they enable the creation of the complex digital and analog circuits that power contemporary technology. Without their expertise in transforming raw components into integrated systems, the advancements we see in various sectors would not be possible, highlighting their indispensable contribution to the technological landscape.

Essential Skills and Assembly Processes

The role of a circuit board assembler demands a specific set of practical skills, with manual assembly at its core. These professionals are adept at handling a wide array of electronic components, which can range from microscopic surface-mount devices (SMDs) to larger through-hole parts. A key technique in their repertoire is soldering, a process requiring steady hands and a keen eye to create durable electrical connections between components and the circuit board. This often involves both traditional hand soldering and operating automated soldering machinery.

Beyond just placing parts, integration is a crucial aspect of their work. Assemblers must carefully follow detailed blueprints, schematics, and work instructions to ensure that each component is positioned correctly and connected according to precise specifications. This attention to detail is vital for the proper functioning of the final electronic devices. The ability to work methodically and understand the sequence of assembly steps is paramount for successful circuit board fabrication.

Precision, Quality, and Technical Expertise

Precision is not merely a desirable trait for circuit board assemblers; it is an absolute necessity. The minute scale of many electronic components means that even slight deviations in placement or soldering can lead to critical failures in the final product. Assemblers must maintain exceptional accuracy, often working under magnification, to ensure every connection is sound and every component is correctly oriented. This meticulous approach directly contributes to the reliability and longevity of electronic devices.

Furthermore, quality control is an inherent part of the assembler’s responsibilities. They are often tasked with performing visual inspections at various stages of the fabrication process, identifying defects such as poor soldering joints, misaligned components, or incorrect part placement. This proactive approach to quality assurance helps prevent faulty products from progressing further down the production line. The role demands a technician mindset, requiring a foundational understanding of how electronic circuits operate and an ability to troubleshoot minor issues, often collaborating with engineering teams to refine processes and improve product integrity.

Tools and Environment in Circuit Board Assembly

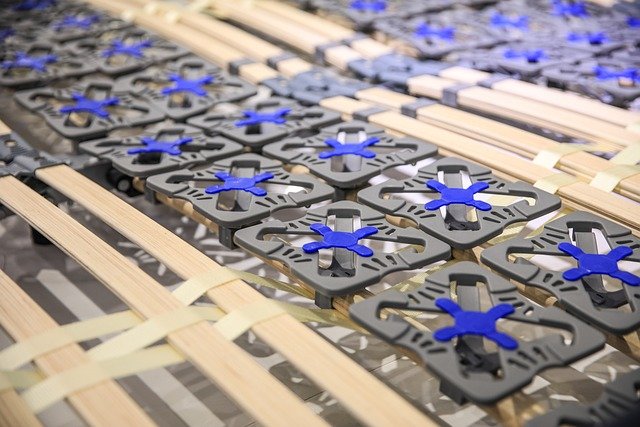

Circuit board assemblers work in environments specifically designed to facilitate the intricate nature of their tasks while maintaining high quality standards. They regularly utilize a range of specialized tools, including precision soldering irons, hot air rework stations, and stereomicroscopes for detailed inspection and assembly of tiny components. Specialized fixtures and jigs are also common, designed to hold circuit boards steady during the fabrication process, ensuring consistent precision and reducing the likelihood of errors.

The work environment often includes controlled conditions to protect sensitive electronics from contaminants and electrostatic discharge (ESD). Assemblers typically work at dedicated workstations equipped with ESD-safe mats, wrist straps, and grounding mechanisms. Cleanroom conditions may also be present in facilities handling highly sensitive devices. Adherence to strict safety protocols and operational guidelines is standard, ensuring both worker safety and the integrity of the delicate electronic components being handled during production.

The role of a circuit board assembler is integral to the advancement and functionality of modern technology. Their careful assembly of electronic components and dedication to precision and quality underpin the creation of countless devices that shape our daily lives. From the initial fabrication to final integration, their technical skills and meticulous approach are essential in bringing complex engineering designs to fruition within the manufacturing sector.