Ensuring Precision in Industrial Material Processing

Precision in material processing is a cornerstone of modern industrial operations, particularly when it comes to shaping metals. The ability to accurately cut and form various metal types is fundamental for producing reliable components across numerous sectors. From automotive parts to aerospace structures and construction elements, the foundational processes of metal cutting dictate the quality, integrity, and functionality of finished products. Understanding the diverse methods and technological advancements in this field is crucial for maintaining high standards in manufacturing and engineering disciplines globally.

Exploring Core Metal Cutting Techniques

Metal cutting encompasses a wide array of techniques, each suited for different materials, thicknesses, and desired precision levels. Mechanical cutting methods, such as shearing, sawing, and punching, rely on physical force to divide or shape metal. Shearing, for instance, is commonly used for straight cuts on sheet metal, while band saws are versatile for various profiles. Thermal cutting techniques, including plasma cutting, laser cutting, and oxy-fuel cutting, utilize heat to melt and remove material. Plasma cutting is effective for electrically conductive metals, offering good speed and quality. Laser cutting provides exceptional precision and fine detail, suitable for intricate designs and a broad range of materials. Waterjet cutting, a non-thermal method, uses a high-pressure stream of water mixed with abrasive particles to cut through virtually any material, minimizing heat-affected zones and maintaining material integrity.

The Role of Precision in Modern Metalwork

Precision is paramount in contemporary metalwork, directly influencing the performance and assembly of components. Achieving high levels of accuracy in cutting ensures that parts fit together seamlessly, reducing waste and rework in subsequent fabrication stages. Advanced machinery integrates computer numerical control (CNC) systems, allowing for programmed, repeatable cuts with minimal human error. This technological integration is vital for industries where tight tolerances are non-negotiable, such as aerospace engineering, medical device manufacturing, and the production of complex components. The pursuit of precision extends beyond the cut itself, encompassing material handling, machine calibration, and environmental controls within the workshop to ensure consistent quality.

Industrial Fabrication and Production Efficiency

In industrial settings, metal cutting is a critical step in the broader fabrication process, directly impacting production efficiency and throughput. The choice of cutting technique and machinery can significantly influence operational costs and lead times. High-speed laser and plasma cutters, for example, can process large volumes of material rapidly, supporting mass manufacturing requirements. Automation plays a key role in optimizing these processes, with robotic systems often integrated to load materials, operate cutting tools, and unload finished parts. This not only boosts efficiency but also enhances safety by minimizing human interaction with hazardous machinery. Streamlined material processing and efficient division of tasks are essential for meeting tight production schedules and maintaining a competitive edge.

Essential Safety Measures in Metal Processing Workshops

Safety is a non-negotiable aspect of any metal processing environment. Operating powerful metal cutting tools involves inherent risks, including exposure to high temperatures, intense light, flying debris, and noise. Comprehensive safety protocols are essential to protect personnel. This includes mandatory use of personal protective equipment (PPE) such as safety glasses, hearing protection, gloves, and protective clothing. Machinery must be regularly inspected and maintained, with all safety guards and interlocks functional. Proper ventilation systems are crucial to remove fumes and dust generated during cutting operations. Training for all operators on safe machine operation, emergency procedures, and material handling is fundamental to preventing accidents and ensuring a secure workshop environment.

Advancements in Metal Cutting Machinery and Technology

The landscape of metal cutting machinery is continuously evolving with technological advancements aimed at improving speed, accuracy, and versatility. Modern tools incorporate sophisticated sensors, real-time monitoring, and artificial intelligence to optimize cutting parameters, predict maintenance needs, and reduce material waste. Fiber laser technology, for instance, offers superior energy efficiency and cutting speeds compared to traditional CO2 lasers, expanding capabilities for various metal types and thicknesses. The integration of software for design and simulation allows engineers to optimize cuts before physical production, further enhancing precision and efficiency. These innovations contribute significantly to the manufacturing sector’s ability to produce increasingly complex components with greater reliability and at lower operational costs.

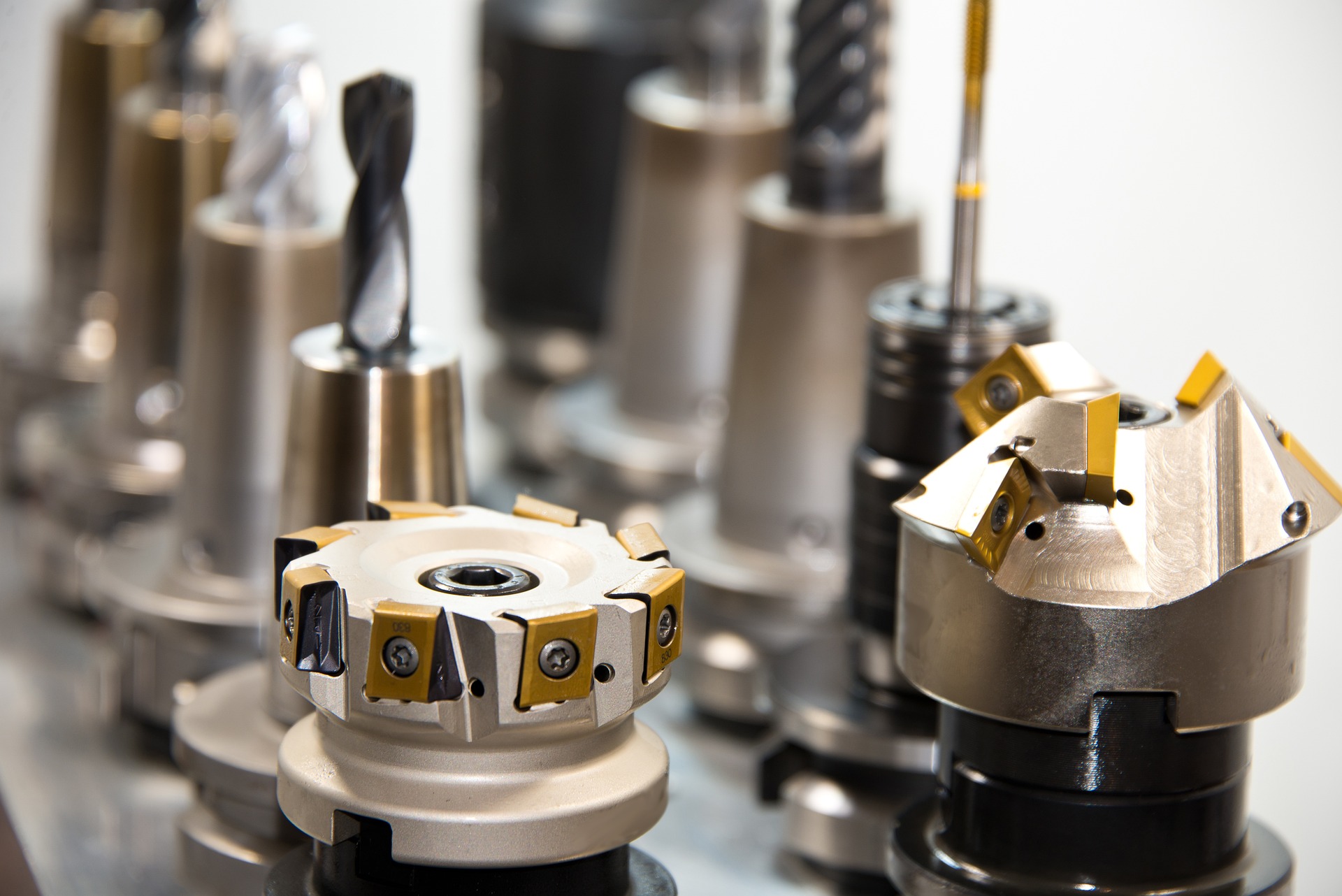

Diverse Types of Metal Cutting Machinery

Metal cutting machinery varies significantly in its application and underlying technology. Shearing machines are robust industrial tools designed for straight-line cutting of sheet metal, often used in initial material preparation. Band saws, available in horizontal and vertical configurations, provide versatility for cutting various metal profiles and shapes. Plasma cutters utilize an ionized gas stream to cut electrically conductive metals, offering a balance of speed and cut quality for medium-thickness materials. Laser cutting machines, particularly fiber lasers, are known for their high precision and ability to process thin to thick metals with intricate geometries. Waterjet cutters excel in cutting heat-sensitive materials and very thick sections, as they do not generate a heat-affected zone. Each type of machinery is selected based on specific project requirements, material properties, desired finish, and production volume, reflecting the ongoing division of labor and specialization in metal processing.