Guiding principles for metal part creation

Creating metal parts involves a blend of technical knowledge, precise execution, and an understanding of material properties. From initial design to the final product, each step demands careful consideration to ensure functionality, durability, and adherence to specifications. This process encompasses various techniques and methodologies, all aimed at transforming raw metal into components essential for countless industries. Mastering these principles is fundamental for anyone involved in metalwork, industrial manufacturing, or advanced fabrication, laying the groundwork for successful and reliable outcomes in diverse applications.

Understanding Metal Fabrication and Materials

Metal fabrication is the overarching process of constructing metal structures by cutting, bending, and assembling. It involves a wide array of techniques, and the choice of material is often the first critical decision. Different metals, such as steel, aluminum, copper, and titanium, possess unique properties regarding strength, weight, corrosion resistance, and workability. Understanding these characteristics is vital for selecting the appropriate material that can withstand the intended operational stresses and environmental conditions. Proper material selection directly impacts the part’s longevity and performance.

The initial stages of fabrication often involve preparing the raw material, which might include cleaning, deburring, or pre-forming. The specific application dictates the material’s form, whether it be sheets, plates, bars, or tubes. Consideration for the material’s response to heat, stress, and subsequent processing steps is crucial. For instance, some alloys require specific heat treatments before or after cutting to prevent cracking or to achieve desired hardness, highlighting the importance of a comprehensive understanding of metallurgy in metal part creation.

Precision Machining and Cutting Techniques

Precision is paramount in modern metal part creation, ensuring components fit together accurately and perform as intended. Machining involves removing material from a workpiece using various tools to achieve a desired shape, size, or surface finish. Common machining operations include turning, milling, drilling, and grinding, each contributing to the final form and tolerances of the part. Advanced computer numerical control (CNC) machines are widely used in industrial settings to automate these processes, achieving high levels of accuracy and repeatability.

Cutting techniques are diverse, ranging from traditional methods like sawing and shearing to more advanced processes such as laser cutting, plasma cutting, and waterjet cutting. Laser cutting uses a focused high-power laser beam to melt and vaporize material, offering exceptional precision for intricate designs and various material thicknesses. Plasma cutting employs an accelerated jet of hot plasma, effective for cutting thicker metals quickly. Waterjet cutting uses a high-pressure stream of water, often mixed with an abrasive, suitable for materials sensitive to heat or those that are extremely hard, ensuring versatility in metal processing.

Essential Industrial Tools and Workshop Equipment

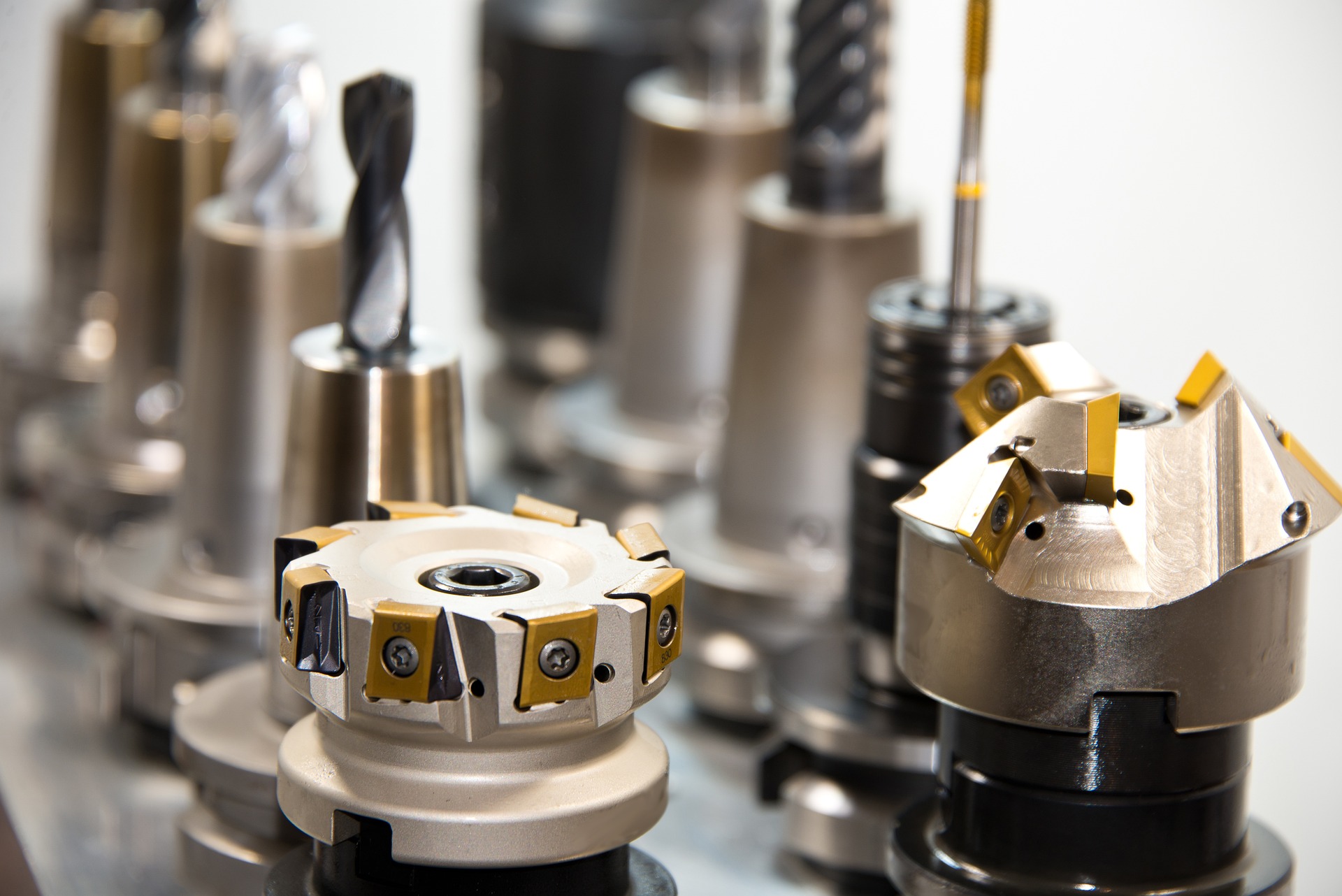

A well-equipped workshop is foundational for effective metal part creation. The range of tools and equipment required varies significantly based on the scale and complexity of the projects. Basic tools include measuring instruments like calipers and micrometers, hand tools for marking and fitting, and various clamps and vises for securing workpieces. Power tools such as angle grinders, drills, and band saws are indispensable for many cutting and shaping tasks.

For industrial applications, larger and more specialized equipment becomes necessary. This includes heavy-duty presses for bending and forming, welding machines for joining components, and sophisticated machining centers like multi-axis CNC mills and lathes. Specialized metal cutters are designed for specific tasks, from abrasive saws for robust material removal to specialized shears for clean, straight cuts on sheet metal. The maintenance and calibration of all equipment are crucial for maintaining accuracy and operational safety.

Prioritizing Efficiency and Safety in Metalwork

Efficiency in metal part creation is achieved through optimized workflows, appropriate tool selection, and minimizing waste. Planning the sequence of operations, nesting parts for efficient material usage, and utilizing automated systems can significantly reduce production time and costs. Regular maintenance of machinery and tools also contributes to efficiency by preventing breakdowns and ensuring consistent performance. Investing in training for personnel on efficient operating procedures can also yield substantial benefits in productivity.

Safety is non-negotiable in any metalwork environment due to the inherent risks involved with heavy machinery, sharp tools, and hot materials. Implementing strict safety protocols, providing personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection, and ensuring proper ventilation are critical. Machine guarding, emergency stop mechanisms, and regular safety training sessions help mitigate hazards. A culture of safety awareness among all personnel is essential to prevent accidents and ensure a secure working environment.

Optimizing Metal Processing and Manufacturing

Optimizing metal processing and manufacturing involves a holistic approach that considers every stage of production. This includes design for manufacturability, where parts are designed to be easily and efficiently produced, reducing material waste and complex operations. Implementing lean manufacturing principles can help identify and eliminate waste in the production flow, from material handling to final assembly. Quality control measures, such as dimensional inspections and material testing, are integrated throughout the process to ensure that all parts meet required specifications and standards.

Continuous improvement is a key aspect of optimizing manufacturing. This involves regularly reviewing processes, adopting new techniques, and integrating advanced equipment to enhance performance. For example, exploring additive manufacturing (3D printing) for certain metal parts can offer new possibilities for complex geometries and rapid prototyping, complementing traditional subtractive methods. The goal is to achieve a balance between speed, cost, and quality, adapting to technological advancements and market demands to maintain a competitive edge in the industrial landscape.

Creating metal parts is a multifaceted discipline that requires a deep understanding of materials, precise execution of techniques, and a commitment to safety and efficiency. By adhering to established principles in material selection, machining, cutting, and overall manufacturing processes, it is possible to produce high-quality components that meet the rigorous demands of various industries. The continuous evolution of technology and methodologies further refines these principles, driving innovation and improving the capabilities of metal part creation.