Key Considerations for Metal Construction Projects

Metal construction projects demand careful planning and execution, particularly when it comes to the precise cutting and shaping of materials. The integrity and functionality of any metal structure heavily rely on the quality of its components, which are often formed through various metal cutting processes. Understanding the different techniques, equipment, and material properties involved is fundamental for achieving durable and reliable results in fabrication and assembly stages, ensuring project success and longevity.

Understanding Metal Cutting in Fabrication

Metalwork and fabrication are foundational to many industries, from construction to automotive. At the heart of these operations is the process of cutting, which transforms raw metal stock into usable components. The accuracy of these initial cuts directly influences the quality of the final product, affecting how parts fit together during assembly and the overall structural integrity. Whether creating straight edges for beams or intricate shapes for custom designs, selecting the appropriate cutting method is crucial for minimizing material waste and ensuring that every piece meets exact specifications for the engineering requirements.

Achieving Precision in Industrial Shearing

Industrial shearing represents a vital method for efficiently processing sheet metal and plates. This technique involves using a straight blade to cut metal with high force, resulting in clean, straight edges. Precision in industrial shearing is paramount, especially in large-scale manufacturing and processing where even minor inaccuracies can lead to significant material loss or structural weaknesses. Modern shearing equipment often incorporates advanced controls and measuring systems to achieve high-tolerance cuts, ensuring consistency across vast quantities of material. This level of accuracy is essential for subsequent fabrication steps and the overall success of metal construction projects.

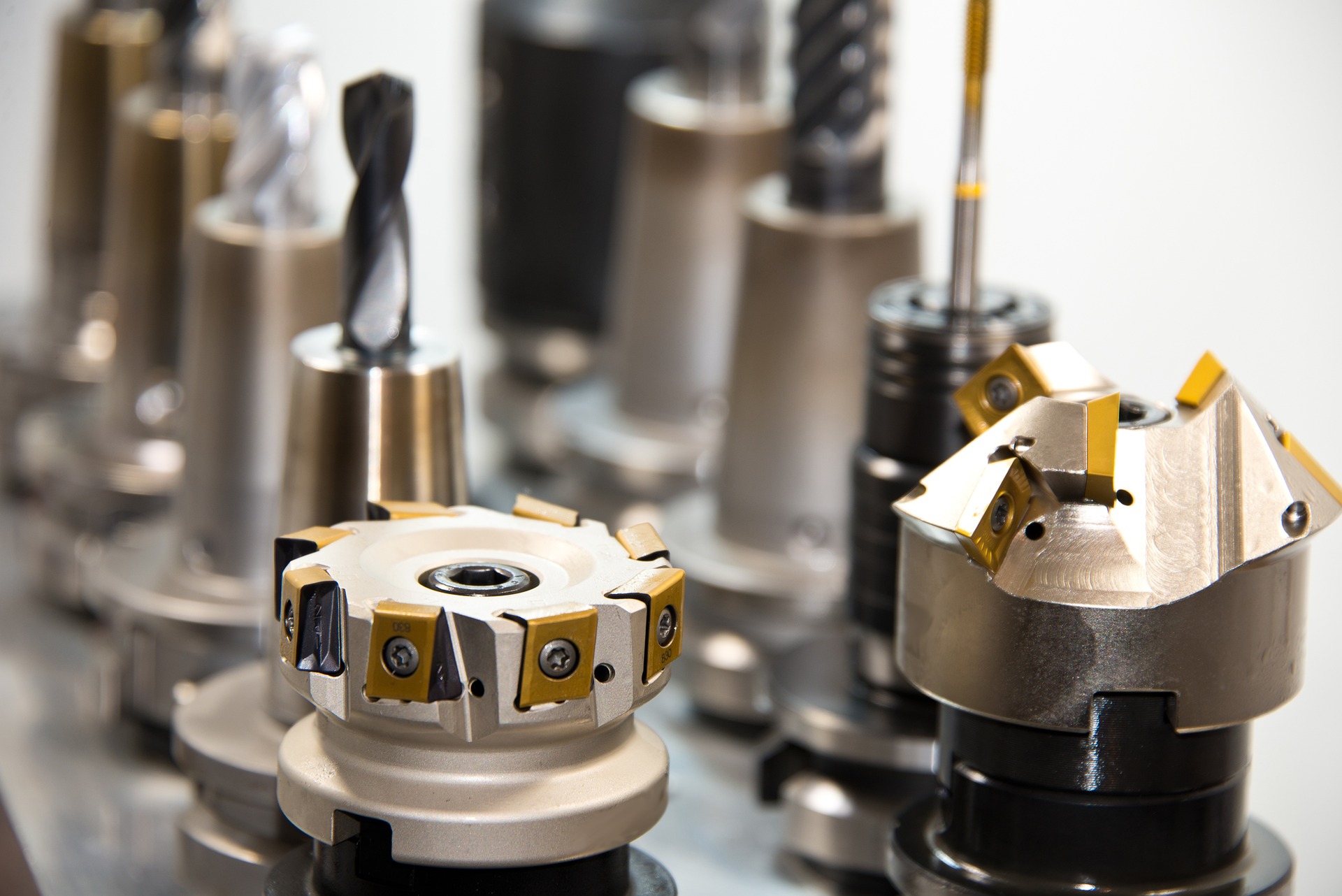

Essential Tools and Equipment for Metal Workshops

Equipping a metal workshop with the right tools and equipment is central to effective metal processing. Beyond basic hand tools, power tools such as angle grinders, portable band saws, and abrasive chop saws are common for various cutting and shaping tasks. For more advanced machining and fabrication, specialized equipment like plasma cutters, laser cutters, and waterjet cutters offer capabilities for high-precision, intricate cuts on a wide range of metal materials. The choice of equipment depends on the type of material, desired precision, volume of work, and specific engineering demands, all contributing to a productive and safe workshop environment.

Techniques for Severing Various Metal Materials

The diverse properties of metal materials like steel, aluminum, and copper necessitate different severing techniques. Steel, known for its strength, might be cut using plasma, laser, or oxy-fuel methods, depending on thickness and required edge quality. Aluminum, being softer and more thermally conductive, often benefits from plasma or laser cutting, which minimize heat distortion. Copper, with its high thermal conductivity, requires careful consideration to prevent melting, often favoring laser or waterjet cutting for precision. Understanding these material characteristics is key to selecting the most effective and efficient cutting process, ensuring optimal results without compromising material integrity or project timelines.

Optimizing Metal Processing for Engineering Projects

Efficient metal processing is a critical factor in the successful execution of engineering projects. From the initial cutting to subsequent machining, bending, and welding, each step must be optimized to ensure quality and adherence to schedules. This involves not only selecting the right cutting tools and techniques but also implementing robust quality control measures throughout the fabrication process. Regular inspection of cut edges, dimensional accuracy, and material integrity helps prevent defects and rework. By streamlining metal processing, engineering projects can achieve their objectives more reliably, deliver structures that meet stringent performance standards, and maintain overall project efficiency.

| Product/Service Name | Provider (General Type) | Key Features | Cost Estimation |

|---|---|---|---|

| Angle Grinder | Handheld Power Tool | Versatile for small cuts, grinding, and deburring; portable. | $50 - $200 |

| Portable Band Saw | Handheld or Benchtop Tool | Clean cuts on various profiles; less sparks than grinders; quieter. | $200 - $800 |

| Plasma Cutter | Specialized Equipment | Fast, precise cuts on conductive metals (steel, aluminum, copper); portable and industrial models. | $500 - $5,000+ |

| Abrasive Chop Saw | Benchtop Power Tool | Quick, straight cuts on metal stock; generates heat and sparks. | $100 - $500 |

| Hydraulic Shear Machine | Industrial Equipment | High-volume, straight-line cutting of sheet metal; high precision. | $10,000 - $100,000+ |

| Fiber Laser Cutter | Advanced Industrial System | Extremely high precision and speed; minimal material distortion; versatile for complex shapes. | $50,000 - $500,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, the success of metal construction projects hinges on a thorough understanding of metal cutting principles and practices. From the fundamental role of cutting in fabrication to achieving precision in industrial shearing, selecting the right tools and techniques for various materials, and optimizing overall processing, each consideration contributes significantly to the final outcome. Careful planning and execution in these areas ensure that metal components are produced accurately, efficiently, and to the highest standards, laying a solid foundation for durable and reliable structures in diverse engineering applications.