Liquidity Detection: Methods and Technologies for Liquid Sensing

Detecting the presence, level, or movement of liquids is a practical challenge across laboratories, manufacturing, environmental monitoring, and safety systems. Liquidity detection refers to a set of methods and tools used to confirm whether liquid is present, to measure its quantity or level, and to monitor properties relevant to a process. Approaches range from hands-on lab techniques to automated sensor networks tied to data systems. This article outlines common methods, practical considerations for sampling and instrumentation, and how data and computers are used to interpret liquid-related signals.

Pipette: role in liquid sampling

A pipette remains one of the most fundamental tools in laboratory liquidity detection workflows. It transfers small, controlled volumes, enabling assays and measurements that determine whether a liquid contains specific constituents or meets a defined volume threshold. For many scientific tests, a pipette’s accuracy and technique directly affect detection outcomes: poor pipetting can introduce air bubbles, cross-contamination, or volume errors. When using a pipette for liquidity checks, standard practices include calibrating equipment, using the correct tip size for the sample volume, and following single- or multi-step dilution procedures to bring measurements into an instrument’s reliable range.

Scientific factors affecting liquidity tests

Scientific considerations determine which detection approach is appropriate. Viscosity, surface tension, density, conductivity, and chemical composition all influence sensor selection and method sensitivity. Temperature and pressure alter liquid properties and may change sensor response. Validation against reference standards and repeatability testing are necessary to interpret results reliably. In regulated contexts, documented standard operating procedures and traceable calibration are required. Error sources—evaporation of volatile samples, sorption to tubing, or particulate matter—should be addressed in study design to produce defensible data.

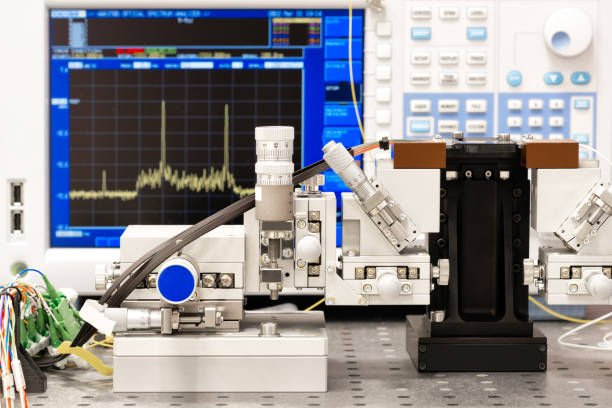

Sensor types for detecting liquids

Several sensor families are commonly used to detect liquids or measure levels: optical (infrared, laser, or photodiodes), capacitive, ultrasonic, float/level switches, conductivity probes, and pressure-based sensors. Optical sensors can detect surface presence or droplets by changes in reflected or transmitted light. Capacitive sensors sense changes in dielectric constant when a liquid approaches. Ultrasonic sensors measure distance to a liquid surface without contact, useful in tanks. Each sensor type has trade-offs in sensitivity, contact/non-contact operation, required maintenance, and compatibility with the liquid’s chemical properties. Selecting the right sensor depends on environment, required resolution, and potential fouling.

Sample handling and preparation

A representative sample is essential for accurate liquidity detection, especially when chemical or microbiological properties are assessed. Sample volume, container material, preservatives, and transport conditions influence integrity. For small volumes, pipettes and microtubes are common; for bulk fluid, automated samplers or inline taps may be used. Filtration or dilution may be necessary to prevent clogging sensors or exceeding instrument dynamic ranges. Consistency in sample collection—timing, depth, and mixing—reduces variability. Documentation of chain-of-custody and storage conditions also supports reliable interpretation of measured results.

Computer integration and data analysis

Modern liquidity detection systems increasingly pair sensors with computers for data acquisition, signal processing, and decision rules. A data logger or embedded microcontroller can record sensor output, apply filters to remove noise, and implement thresholds or alarms. Software can combine multiple sensor inputs (for example, temperature and conductivity) to improve confidence in detection and reduce false positives. Machine learning approaches may be used in complex applications to recognize patterns indicative of leaks or contamination, though they require labeled training data and validation. Attention to cybersecurity, data integrity, and backup is important when detection systems influence safety or automated controls.

Conclusion

Liquidity detection spans straightforward manual checks to integrated sensor networks with computer-driven analysis. Choosing an effective approach requires matching sensor type and sampling method to the liquid’s properties, the operational environment, and the required confidence level of results. Robust scientific practices—appropriate sampling, calibration, and documented procedures—remain central to reliable detection regardless of technology. As systems evolve, combining complementary sensors with careful data analysis can improve detection accuracy while maintaining traceability and repeatability.