Manufacturing Jobs and Career Paths in the UK Industry

Manufacturing jobs cover a wide range of roles across production, quality control, engineering and logistics. For people considering a career in manufacturing, understanding the typical tasks, required skills and workplace environment can help match ambitions to available roles. This article outlines what manufacturing work looks like, common career routes, the UK employment context, skills and technology expectations, and what to expect in factory roles and training options.

Manufacturing: what does the work involve?

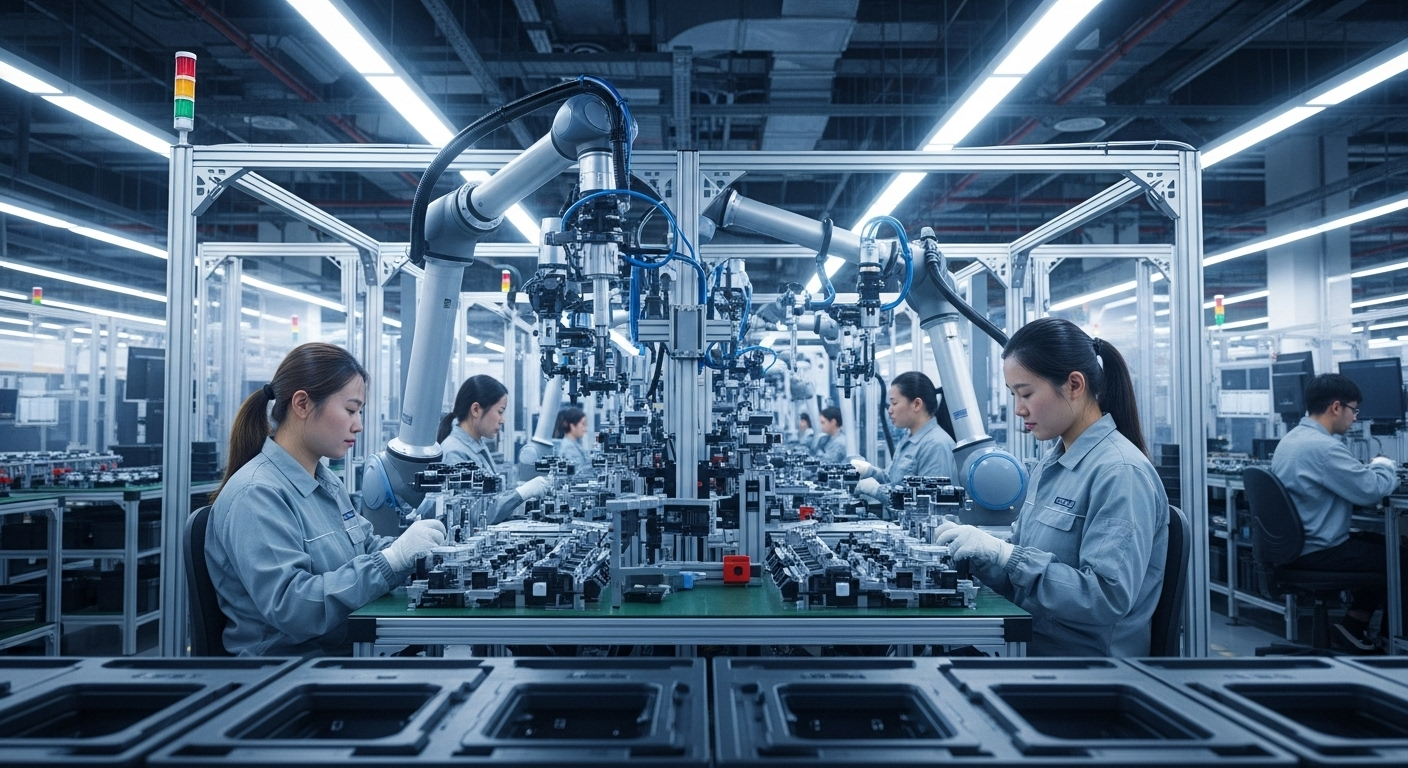

Manufacturing work typically centres on producing goods from raw materials through a sequence of processes. Tasks can include machine operation, assembly, monitoring production lines, quality inspection and basic maintenance. Many roles require following safety procedures and production schedules, reading technical drawings, and working with measurement tools. Work can be manual, semi-automated or fully automated depending on the production environment. Practical problem‑solving, attention to detail and consistent quality focus are common day‑to‑day requirements.

Career paths in manufacturing

A manufacturing career can progress along technical, supervisory or specialist routes. Entry-level positions often lead to roles such as machine operator, skilled technician, or inspector. With experience and qualifications—such as vocational certificates or apprenticeships—workers can move into team lead, engineering, maintenance, production planning, or quality assurance roles. Some people transition into supply chain, health and safety, or engineering design. Continuous learning and obtaining industry-recognised qualifications help with progression and open pathways into management and technical specialist roles.

UK employment landscape for the industry

The UK manufacturing sector includes a mix of automotive, aerospace, food and drink, pharmaceuticals and general engineering firms. Employment opportunities can vary regionally, with clusters near industrial hubs or ports. Employers often seek candidates with practical skills, basic numeracy, and familiarity with manufacturing processes. Apprenticeships and vocational training remain important entry routes. For those relocating or searching locally, consider local services such as college courses, training providers and employer-supported apprenticeships that connect candidates to vacancies and hands-on experience.

Industry skills, technology and standards

Modern industry increasingly blends traditional skills with digital and technical abilities. Knowledge of health and safety standards, lean manufacturing principles, and basic IT for production systems is valuable. Familiarity with CNC machines, PLCs, robotics or quality management systems can be a significant advantage in certain sectors. Employers also value soft skills—communication, teamwork and adaptability—because production environments often require coordination across shifts and departments. Ongoing upskilling is common as factories adopt new automation and data-driven quality controls.

Factory roles, shifts and working conditions

Factory roles vary from manual assembly and packing to technical maintenance and process engineering. Many factories operate shifts to provide continuous production; shift patterns can include early, late and night shifts, and employers typically outline shift expectations in job descriptions. Working conditions depend on the product and plant: some environments are climate‑controlled and low-noise, while others may involve heavier manual handling or exposure to industrial processes. Health and safety training, proper personal protective equipment and clear supervision are standard controls to manage workplace risk.

Conclusion

Manufacturing jobs offer a broad spectrum of roles for different interests and skill sets, from hands-on production work in factories to technical and managerial careers in the wider industry. In the UK, apprenticeships, vocational courses and local training services provide practical pathways into the sector, while ongoing skill development supports career progression as technology and processes evolve. Understanding typical duties, expected skills and working patterns can help candidates choose the right entry point and plan their next steps.