Mastering Electronic Component Placement

Electronic component placement is a foundational process in the creation of virtually all modern electronic devices. It involves the precise positioning and attachment of various components, from tiny resistors to complex integrated circuits, onto a printed circuit board (PCB). This intricate work requires a combination of technical skill, attention to detail, and often specialized equipment to ensure the functionality and reliability of the final product. Understanding the nuances of this process is crucial for anyone involved in the manufacturing or development of electronics, highlighting the critical role played by skilled assemblers in bringing technological innovations to life.

How Electronics Assembly and Manufacturing Works

Electronics assembly is a sophisticated process that transforms raw materials and individual components into functional electronic products. This involves several stages, beginning with the design of the circuit board and culminating in the final testing of the assembled device. The manufacturing environment for electronics often utilizes both automated machinery and skilled manual labor, particularly for intricate or specialized tasks. The goal is to achieve high precision and consistency across all units produced, which is essential for the performance and longevity of electronic devices. Each step in the assembly line contributes to the overall quality and reliability, making attention to detail paramount.

Understanding Circuitry and Component Production

At the heart of any electronic device lies its circuitry, which dictates how electricity flows and how components interact. Printed circuit boards (PCBs) serve as the physical foundation for this circuitry, providing conductive pathways and mounting points for various components. The production of these components themselves, ranging from surface-mount devices (SMDs) to through-hole components, involves complex fabrication processes. Understanding the characteristics and functionalities of these individual components is essential for effective placement and assembly. The careful selection and handling of each part directly impact the circuit’s ability to perform its intended function, emphasizing the importance of a meticulous approach.

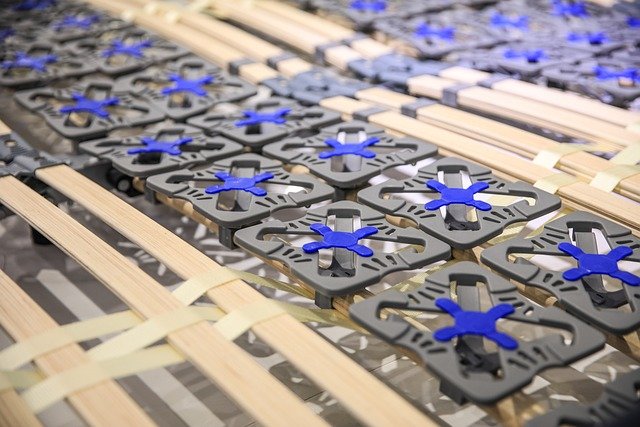

Key Technologies in Hardware Fabrication

Modern hardware fabrication relies heavily on advanced technology to achieve the necessary speed, accuracy, and miniaturization. Automated pick-and-place machines are central to high-volume assembly, capable of precisely positioning thousands of components per hour. These machines are programmed to follow exact specifications, ensuring consistent placement on the circuit board. Beyond automation, technologies like reflow soldering ovens, wave soldering machines, and advanced inspection systems (such as Automated Optical Inspection or AOI) are integral to the production line. The integration of these technologies allows for efficient and reliable manufacturing of complex electronic devices and systems, pushing the boundaries of what is technically possible in electronics.

The Role of Soldering and Precision in Assembly

Soldering is a critical process in electronic assembly, creating the electrical and mechanical connections between components and the circuit board. Whether through manual hand soldering or automated techniques like reflow and wave soldering, the quality of these connections directly impacts the device’s performance and durability. Precision is not merely a desirable trait but a fundamental requirement in this field. Misaligned components or poor solder joints can lead to electrical shorts, open circuits, or intermittent failures. Assemblers must demonstrate exceptional dexterity and a keen eye for detail, ensuring every connection meets stringent quality standards to prevent defects and ensure the long-term reliability of the electronic product.

Applying Engineering Principles to Electronic Devices and Systems

The work involved in electronic component placement is deeply rooted in engineering principles. From reading schematics and blueprints to understanding the thermal and electrical properties of materials, a solid grasp of fundamental engineering concepts is invaluable. Assemblers often work closely with design engineers, providing feedback on manufacturability and identifying potential issues during the production phase. This collaborative approach ensures that the design translates effectively into a physical product. The continuous drive to create more compact, powerful, and efficient electronic devices and systems means that the principles of electrical engineering, mechanical engineering, and materials science are constantly applied and refined throughout the assembly and manufacturing process.

General Insights into Assembly Tooling and Equipment

While specific costs or provider comparisons are not applicable to the nature of this discussion, understanding the general categories of equipment used in electronic assembly provides valuable context. The tooling ranges from basic hand tools for manual tasks to sophisticated automated systems. For manual assembly and rework, essential items include soldering irons, tweezers, magnifiers, and various cutting tools. These allow for precise handling and manipulation of small components. For higher volume or more complex production, specialized machinery such as automated pick-and-place machines, stencil printers, and reflow ovens are standard. These systems represent significant investments, reflecting the need for accuracy and efficiency in modern electronics manufacturing. The choice of equipment often depends on the scale of production, the complexity of the circuit boards, and the specific types of components being assembled.

Electronic component placement is a cornerstone of the electronics industry, demanding a blend of technical knowledge, practical skills, and unwavering attention to detail. The process is a testament to precision manufacturing, where each component’s correct positioning and secure attachment contribute to the functionality of complex electronic systems. As technology continues to advance, the methods and tools used in assembly will also evolve, but the fundamental need for careful, accurate component placement will remain a critical aspect of bringing new electronic innovations to the world.