Sustaining performance in demanding linear drive applications

Hydraulic cylinders are fundamental components in a vast array of industrial and mobile applications, providing the robust linear force necessary for demanding operations. Their ability to convert hydraulic fluid pressure into precise and powerful linear motion makes them indispensable across various sectors, from heavy construction equipment to intricate manufacturing processes. Understanding the principles behind their operation and the factors influencing their sustained performance is crucial for operational efficiency and reliability in these critical systems.

Understanding Hydraulic Actuation in Industrial Machinery

Hydraulic actuation is a cornerstone of modern industrial machinery, enabling the movement and control of heavy loads with remarkable power. Hydraulic cylinders, as the primary actuators, are central to this capability, converting the energy of pressurized fluid into a powerful linear force. This mechanical advantage allows industrial systems to perform tasks such as lifting, pushing, pulling, and clamping with high precision and significant force, making them essential in sectors like manufacturing, mining, and construction. Their robust design ensures reliability even in the most challenging operational environments.

Principles of Linear Motion and Fluid Power Systems

At the core of hydraulic cylinder operation are the principles of fluid power systems. These systems utilize an incompressible fluid, typically oil, to transmit force from one point to another. When a pump pressurizes the fluid, it creates hydraulic energy that is then directed to the cylinder. Inside the cylinder, this pressure acts on a piston, driving it linearly along the barrel. This controlled linear motion is vital for many applications, offering advantages in terms of force density and the ability to hold a load without continuous power input, contributing to overall system stability and performance.

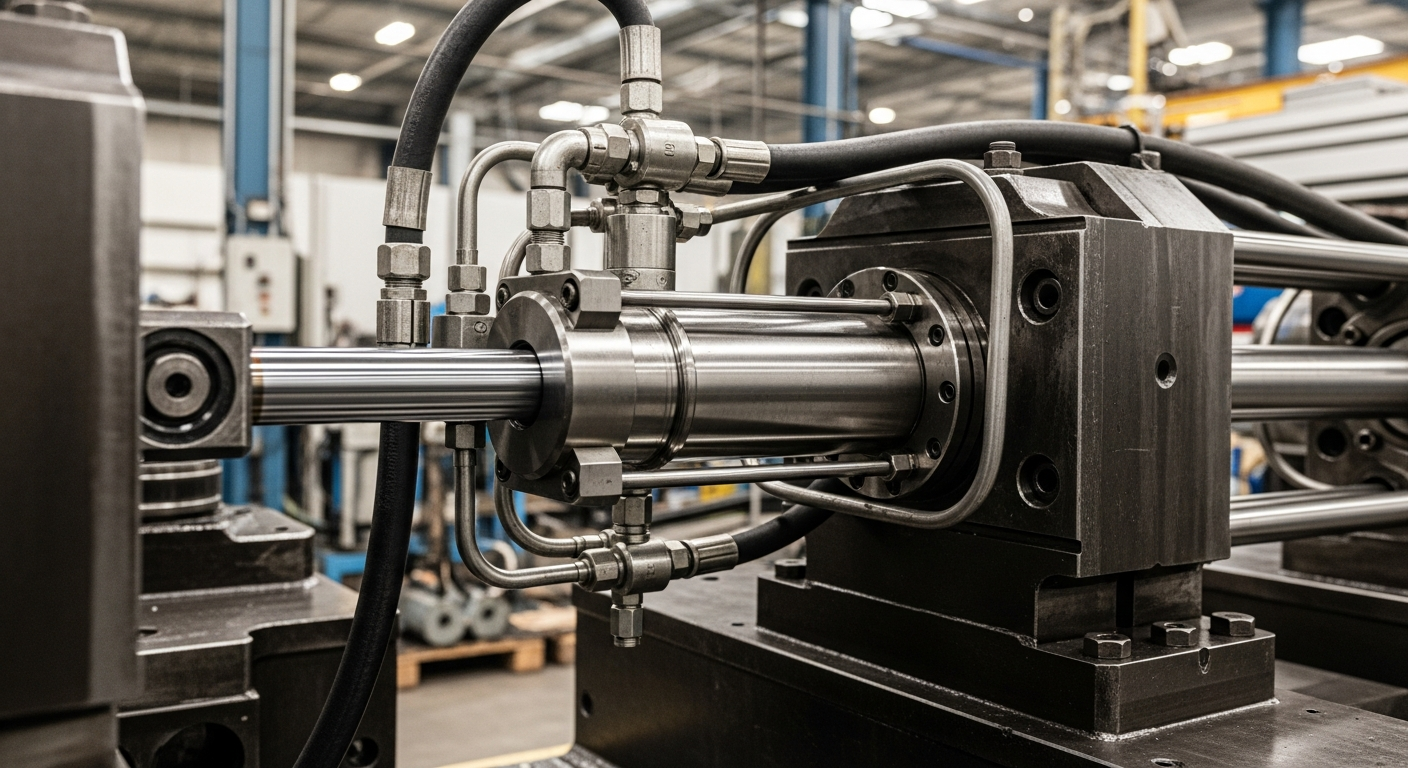

Key Components and Engineering Design for Performance

The sustained performance of a hydraulic cylinder is heavily reliant on its key components and their meticulous engineering design. Essential parts include the cylinder barrel, piston, piston rod, end caps, and various seals. The material selection for these components, such as high-strength steel for barrels and rods, is critical for durability and resistance to wear and fatigue. The design of the seals, in particular, plays a pivotal role in preventing leaks and maintaining system pressure, directly influencing the cylinder’s efficiency and longevity. Advanced engineering focuses on optimizing these elements for specific application demands, ensuring reliable operation.

Enhancing Efficiency and Control in Drive Mechanisms

Efficiency and precise control are paramount in modern hydraulic drive mechanisms. Hydraulic cylinders contribute significantly to this by offering a high degree of controllability over speed and force. Integrating them with sophisticated control systems, such as proportional valves and feedback mechanisms, allows for fine-tuned adjustments to the linear motion, enabling complex and precise operational sequences. This level of control not only optimizes the performance of the equipment but also enhances safety and reduces energy consumption by ensuring that only the necessary power is applied for each task.

The Role of Hydraulic Cylinders in Automation Equipment

In the realm of automation, hydraulic cylinders are indispensable for tasks requiring substantial force and consistent performance. They are widely used in automated assembly lines, material handling systems, and robotic applications where repetitive, high-force operations are common. Their inherent power density allows automation equipment to handle heavy workpieces or exert significant clamping force, contributing to increased productivity and reduced manual labor. The reliability and durability of these cylinders ensure continuous operation in automated industrial settings, minimizing downtime.

Maintaining Force and Mechanics for Sustained Operation

Maintaining the required force and mechanical integrity of hydraulic cylinders is crucial for their sustained operation in demanding applications. This involves regular inspection and maintenance, including checking for seal wear, rod damage, and proper fluid levels and quality. The mechanics of the cylinder, such as the alignment of the piston rod and the integrity of mounting points, directly influence its ability to consistently deliver force without undue stress or premature failure. Adherence to manufacturer guidelines for service intervals and the use of appropriate hydraulic fluids are key practices for ensuring long-term performance and reliability.

Hydraulic cylinders remain vital for a wide range of demanding linear drive applications, underpinning the functionality of heavy machinery and advanced automation systems globally. Their ability to provide powerful, controlled linear motion is a testament to the robust principles of fluid power and precision engineering. By understanding their fundamental mechanics, carefully considering their design, and implementing diligent maintenance practices, industries can ensure the sustained performance and reliability of these essential components, supporting operational efficiency across diverse sectors.