The Role of Actuators in Modern Manufacturing

Actuators are fundamental components in the landscape of modern manufacturing, serving as the crucial link between control signals and physical movement. They are responsible for converting various forms of energy, such as fluid pressure or electrical current, into mechanical force and motion. This capability allows machinery to perform tasks ranging from precise positioning to heavy lifting, making them indispensable across virtually all industrial sectors globally. Understanding their function and diverse applications is key to appreciating the sophistication and efficiency of contemporary production processes.

Understanding Actuation in Industrial Engineering

Actuation is the process of putting something into motion or action, and in industrial engineering, it refers to the operation of a device that controls a mechanism or system. These devices, known as actuators, are vital for automation and the precise control of industrial machinery. They enable equipment to perform specific tasks, translating signals from a control system into physical linear motion or rotational movement. This capability is at the heart of modern manufacturing, where precision, speed, and reliability are paramount for efficient production and operation.

Exploring Diverse Actuator Systems

Actuators come in several forms, each suited for different applications based on their power source and operational characteristics. The primary types include hydraulic, pneumatic, and electric actuators. Hydraulic systems utilize an incompressible fluid, typically oil, under pressure to generate significant force. This fluid power is highly effective for heavy-duty applications requiring substantial force and precise control, making them common in construction equipment and heavy industrial machinery. Pneumatic systems, on the other hand, use compressed air to generate movement and force. They are often favored for their cleanliness, speed, and suitability in environments where fire hazards are a concern. Electric actuators convert electrical energy into mechanical movement using motors, offering high precision, easy integration with digital control systems, and energy efficiency, particularly for applications not requiring extreme force.

Generating Linear Motion and Force

Central to an actuator’s function is its ability to generate controlled linear motion or rotational movement and apply specific force or pressure. In the context of linear motion, actuators extend or retract along a straight line, pushing or pulling a load. This is achieved through various mechanics, such as pistons within cylinders for fluid-powered systems or lead screws driven by electric motors. The amount of force an actuator can exert is directly related to its design and the pressure or power supplied to it. For instance, in a hydraulic system, the fluid pressure acting on the piston’s surface area determines the output force, enabling the manipulation of heavy objects or the application of significant clamping pressure in industrial processes.

Essential Components and Control Dynamics

Actuator systems are comprised of several key components that work in concert to achieve desired movements and control. For fluid power systems (hydraulic and pneumatic), these include cylinders, valves, pumps or compressors, and reservoirs. The control systems, often electronic, regulate the flow of fluid or electricity to the actuator, dictating its speed, direction, and position. The dynamics of these systems involve careful calibration to ensure stable, repeatable, and precise movement. Advanced control mechanisms, such as proportional valves and feedback sensors, allow for highly accurate positioning and force control, which is critical for complex industrial processes and automation tasks.

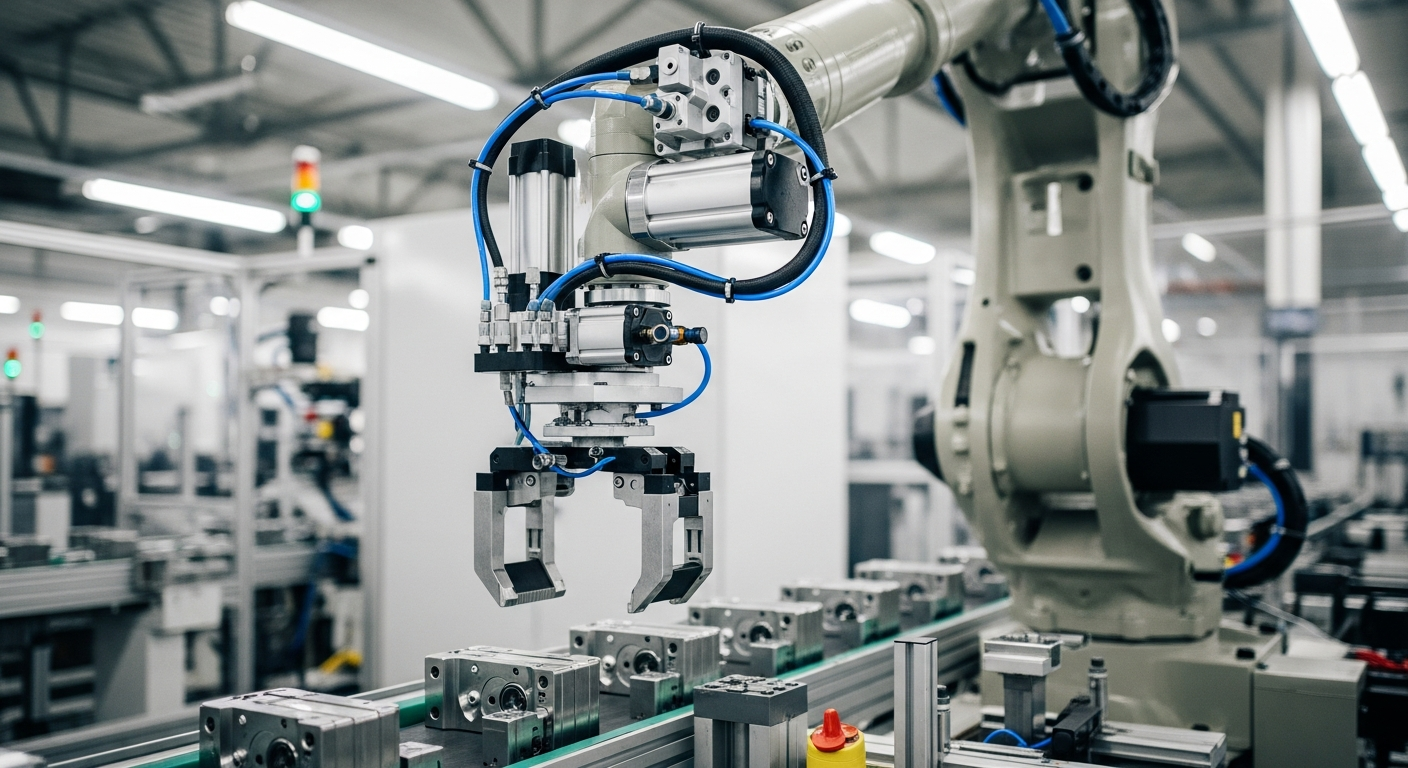

Actuators in Modern Automation and Equipment

Actuators are integral to the advancements in automation and the development of sophisticated industrial equipment. Their ability to precisely control movement and force allows for the mechanization of repetitive tasks, significantly improving efficiency and reducing human error in manufacturing processes. From robotic arms on assembly lines to automated valves in process control systems, actuators are the muscles of modern industrial operations. They facilitate the movement of components, the operation of tooling, and the precise positioning of workpieces, contributing to the overall productivity and capability of contemporary industrial systems across various sectors, including automotive, aerospace, food processing, and material handling.

The Mechanics of Actuator Movement

The underlying mechanics of actuator movement involve the conversion of stored or supplied energy into kinetic energy to produce work. Whether it’s the expansion of compressed air, the flow of pressurized hydraulic fluid, or the rotation of an electric motor, the principle remains consistent: a controlled energy input results in a predictable mechanical output. The design of an actuator, including its size, material, and internal configuration, dictates its performance characteristics such as speed, stroke length, and maximum force. Understanding these mechanical principles is crucial for engineers in selecting and designing effective actuation systems that meet the specific demands of diverse industrial applications and ensure optimal operation and longevity of equipment.

Actuators are foundational elements in the architecture of modern manufacturing. Their diverse types and operational principles allow for a wide range of applications, from delicate precision tasks to robust heavy-duty operations. As industrial processes continue to evolve towards greater automation and efficiency, the role of actuators will remain central, driving innovation and enabling the next generation of sophisticated machinery and production systems.