The Vital Role of Electronic Production Specialists

Electronic production specialists, often known as circuit board assemblers, are fundamental to the creation of virtually every modern electronic device. From the simplest household appliances to complex aerospace systems, their meticulous work ensures the functionality and reliability of the underlying circuitry. These professionals are at the core of the manufacturing process, transforming raw components into integrated systems that power our digital world and enable technological advancements across various industries.

The landscape of modern technology is built upon a foundation of intricate electronic components, and at the heart of their creation are electronic production specialists. These skilled individuals are responsible for the precise assembly of circuit boards, ensuring that each component is correctly placed and connected to form functional electronic devices.

Understanding Electronics Assembly and Components

Electronics assembly involves bringing together a multitude of individual components—resistors, capacitors, microchips, and more—onto a printed circuit board (PCB). This process requires a deep understanding of each component’s function and its correct orientation. Specialists must be adept at interpreting complex schematics and blueprints, which serve as the roadmap for assembly. The accurate placement of these minute parts is critical, as even a slight misalignment can compromise the entire circuitry and the performance of the final product. This foundational work in electronics is where the journey of a device truly begins, laying the groundwork for its eventual operation and integration into larger systems.

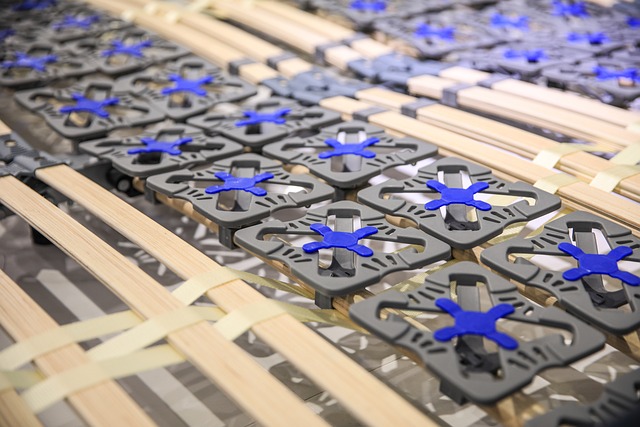

Precision and Quality in Circuitry Manufacturing

Precision is paramount in the realm of circuitry manufacturing. Electronic production specialists often work with extremely small components, demanding steady hands and meticulous attention to detail. The methods of assembly can range from manual soldering for prototypes or specialized applications to operating sophisticated automated machinery for high-volume production. Regardless of the method, the goal remains consistent: to achieve flawless connections and robust structures. Adherence to strict quality control standards is integral, involving visual inspections, electrical testing, and other verification processes to detect and correct any imperfections. This rigorous approach ensures the reliability and longevity of the devices once they are deployed.

The Evolution of Production Technology and Devices

The field of electronic production has undergone significant transformation, driven by rapid advancements in technology. Specialists today utilize a wide array of tools, from advanced soldering stations and microscopes to automated pick-and-place machines and reflow ovens. The continuous evolution of electronic hardware means that production techniques must also adapt, often requiring specialists to learn new processes and equipment. This dynamic environment necessitates ongoing professional development to stay current with the latest innovations in manufacturing. From consumer electronics to industrial control units, the methods of fabrication are constantly refined to meet the demands of increasingly complex and miniaturized products.

Essential Skills for Industrial Fabrication

For those working in electronic industrial fabrication, a specific set of skills is crucial. Manual dexterity, excellent hand-eye coordination, and keen vision are fundamental, especially for tasks involving fine motor skills. A strong grasp of technical documentation, including schematics and work instructions, is essential for accurate assembly. Problem-solving abilities are also highly valued, as specialists may need to diagnose and rectify issues during the production process. Furthermore, an understanding of safety protocols and electrostatic discharge (ESD) prevention is vital to protect both the components and the personnel involved. These competencies contribute directly to the efficiency and integrity of the manufacturing line.

Innovations and Integration in Modern Systems

Modern engineering principles increasingly focus on the seamless integration of electronic components into larger, more complex systems. Electronic production specialists play a critical role in this, ensuring that individual circuit boards are not only functional on their own but also compatible and reliable when combined with other modules. This often involves working with multi-layered PCBs, surface-mount technology (SMT), and through-hole technology (THT), sometimes within the same production run. The drive for smaller, more powerful, and energy-efficient devices pushes the boundaries of what is possible in manufacturing, making the specialist’s role in bringing these designs to fruition more significant than ever.

Electronic production specialists are indispensable contributors to the technological landscape, bridging the gap between design and functional reality. Their expertise in assembly and fabrication ensures that the intricate circuitry underpinning countless devices is brought to life with the necessary precision and quality. The demands of this role highlight a combination of technical skills, attention to detail, and adaptability to evolving technology and innovations within the industrial sector.