Understanding Pressure-Driven Mechanical Systems

Pressure-driven mechanical systems are fundamental to numerous industrial and mobile applications, enabling the generation of substantial force and precise motion. At the heart of many such systems lies the hydraulic cylinder, a seemingly simple device that converts fluid power into linear mechanical force and movement. This technology is critical for tasks ranging from heavy lifting and pressing to intricate positioning, highlighting its versatility and importance across various sectors worldwide.

Understanding Fluid Power and Actuation

Fluid power systems utilize pressurized fluid, typically oil, to transmit energy. Within this context, hydraulic cylinders serve as the primary actuators, converting the hydraulic pressure into mechanical work. This process involves the controlled flow of fluid into a cylinder, pushing a piston, which in turn extends or retracts a rod. The fundamental principle leverages Pascal’s law, where pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. This efficient energy transfer allows for the generation of significant force from relatively modest input pressures, making them indispensable in heavy-duty applications.

Generating Linear Motion with Precision

Hydraulic cylinders are specifically designed to produce linear motion, making them ideal for pushing, pulling, lifting, and clamping operations. The smooth and controlled movement of the piston within the cylinder bore allows for precise positioning and speed control, which is a critical aspect in many industrial engineering applications. Engineers can finely tune the speed and force of extension and retraction by adjusting the flow rate and pressure of the hydraulic fluid. This capability for controlled linear motion is what sets hydraulic systems apart for tasks requiring both power and accuracy, contributing to enhanced performance in automated systems.

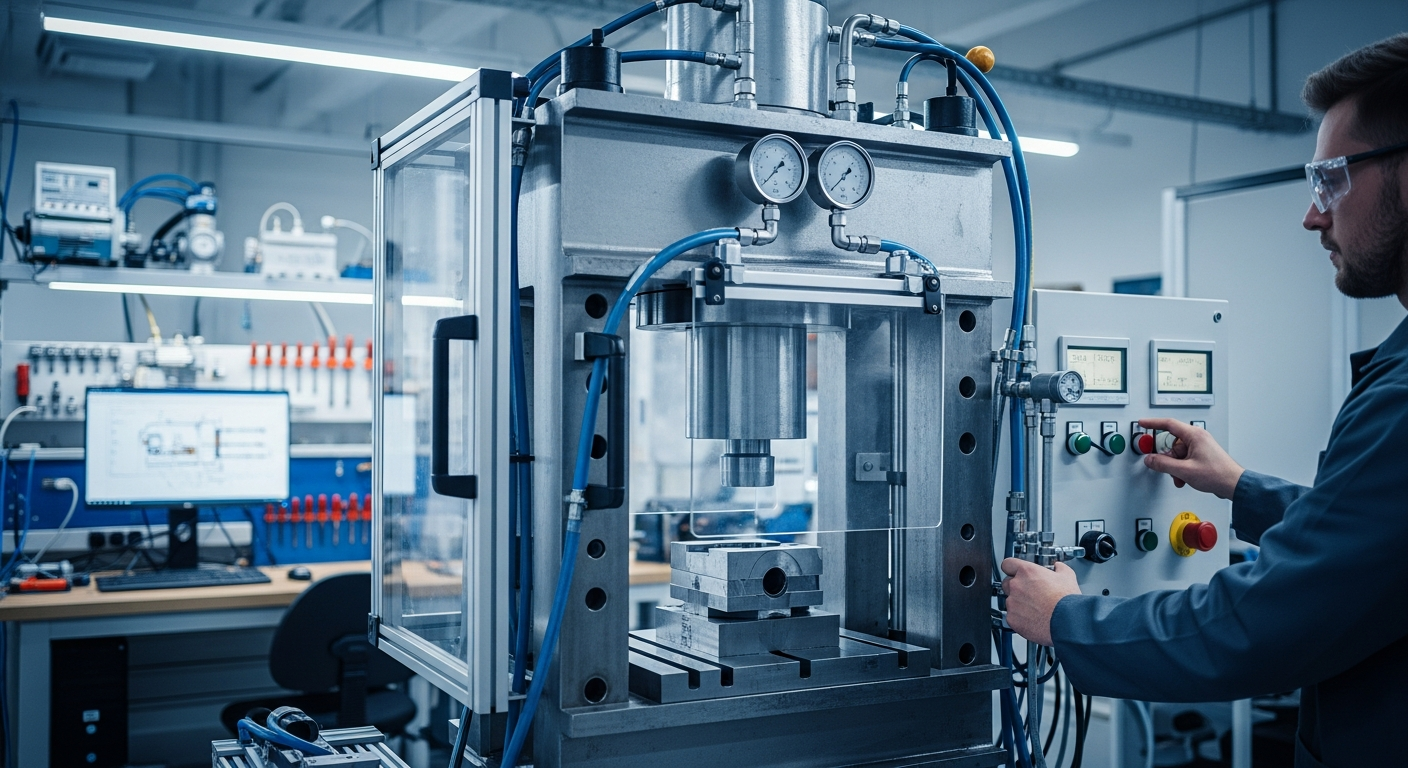

Role in Industrial Machinery and Equipment

From construction equipment like excavators and bulldozers to manufacturing machinery such as presses and injection molding machines, hydraulic cylinders are ubiquitous. Their robust design and ability to withstand high pressure make them suitable for demanding environments where consistent force and reliable movement are paramount. In industrial settings, these components are often integrated into complex automation systems, providing the muscle required for repetitive tasks, material handling, and assembly processes. The durability of these systems ensures long operational lifespans, reducing downtime and maintenance needs.

Managing Force, Pressure, and Control

The effective operation of hydraulic cylinders relies heavily on the meticulous management of force and pressure. Hydraulic pumps generate the necessary pressure, while valves regulate the direction and flow rate of the fluid, thereby controlling the cylinder’s action. This sophisticated control mechanism allows operators to precisely dictate the speed, position, and applied force of the cylinder rod. Advanced hydraulic systems incorporate sensors and electronic controllers to achieve even greater precision and responsiveness, crucial for modern manufacturing and robotics. Understanding these components is key to optimizing system performance and ensuring operational safety.

Key Components and System Performance

A typical hydraulic cylinder consists of several main components: the cylinder barrel, piston, piston rod, end caps (head and cap), and seals. Each part plays a vital role in the cylinder’s overall performance and durability. The barrel contains the fluid and guides the piston, while the piston separates the pressure zones, and the rod transmits the force. High-quality seals are crucial to prevent fluid leakage and maintain pressure integrity, ensuring efficient power transfer. The choice of materials and manufacturing processes significantly impacts the cylinder’s resistance to wear, corrosion, and fatigue, directly affecting its lifespan and reliability in demanding applications.

Diverse Applications and Movement Precision

Hydraulic cylinders find applications across a vast array of industries due to their ability to deliver powerful and controlled movement. In agriculture, they operate implements like plows and loaders. In aerospace, they are used in landing gear and flight control surfaces. The marine industry employs them for steering gears and cargo handling. Their inherent precision makes them suitable for delicate tasks such as in robotics, where accurate actuation is essential for intricate manipulations. This widespread adoption underscores the adaptability and efficiency of hydraulic cylinder systems in meeting diverse operational requirements globally.

Conclusion

Hydraulic cylinders are fundamental enablers of modern mechanical systems, transforming fluid power into linear motion with impressive force and precision. Their robust design and versatile applications contribute significantly to industrial engineering, machinery, and automation across numerous sectors. By understanding the principles of fluid power, pressure, and control, and appreciating the role of each component, one can grasp the essential contribution of these devices to technological advancement and operational efficiency worldwide.