Active cooling and airflow strategies for sustained high-power laps

Sustaining high-power laps in electric karts requires deliberate cooling and airflow strategies to protect components and preserve performance. Effective management of battery and motor temperatures reduces power roll-off, preserves range, and supports regeneration systems. This article outlines practical approaches—from shrouds and directed ducting to sensor-driven cooling and modular component design—while integrating telemetry, diagnostics, safety considerations, and infrastructure needs for tracks and teams.

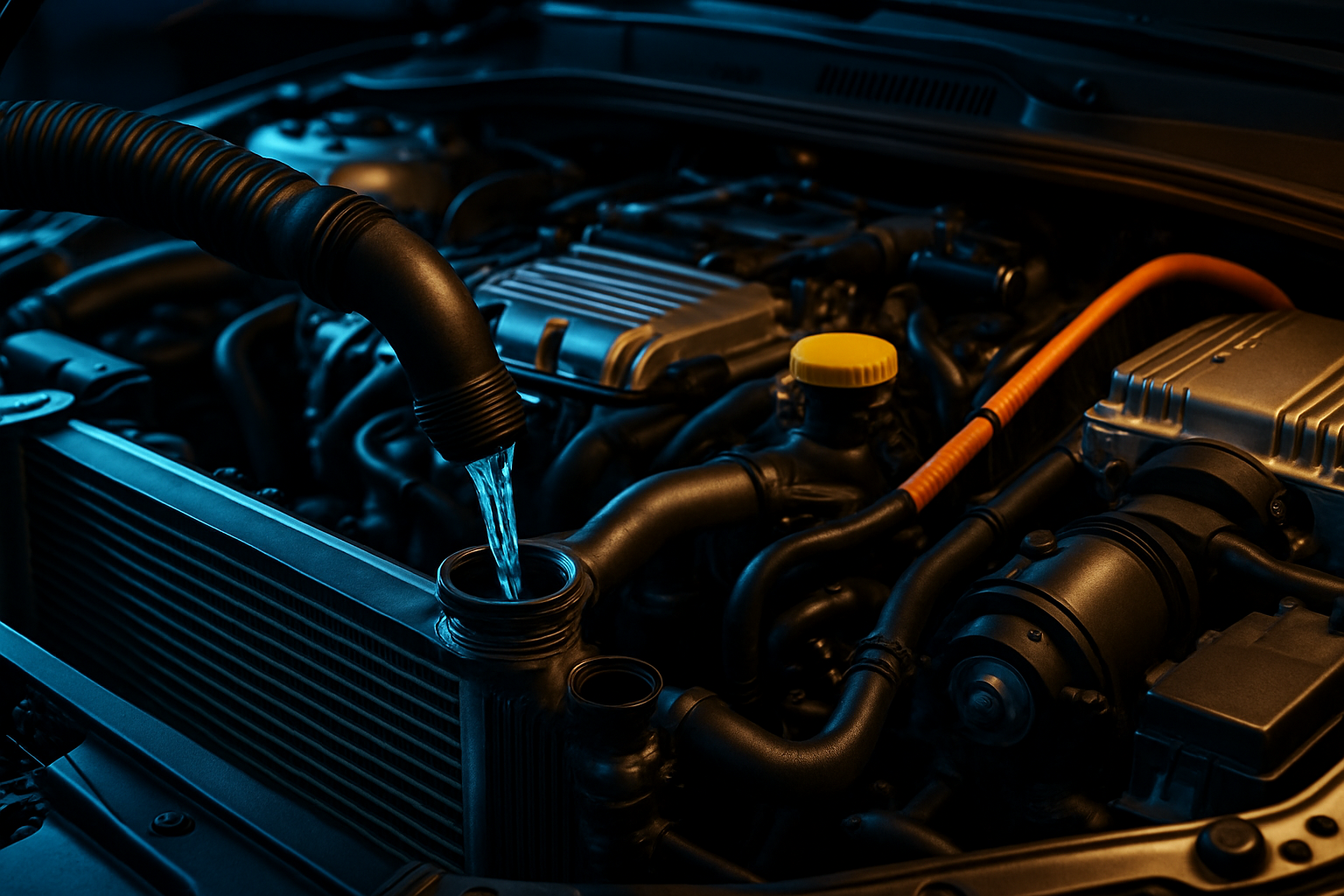

Cooling strategies for sustained power

Active cooling should focus on maintaining consistent component temperatures through a combination of airflow management and targeted heat extraction. Directed ducting and intake shrouds channel ambient air to batteries and motor housings during high-speed sections, while vented fairings avoid trapping heat in straights or corners. Forced-air options—small electric blowers or fan packs—can augment passive flow during slow laps or pit sequences. Acoustic trade-offs matter: fan-induced noise can affect driver communication and track acoustics, so balance fan RPM and duct geometry. Integrating cooling outlets with safety-compliant clearances and track infrastructure minimizes debris ingestion and complies with regulations.

Battery temperature and range effects

Battery thermal control directly influences range and peak power delivery. Keeping cells within an optimal band reduces internal resistance and supports consistent regeneration during braking. Active liquid cooling or phase-change surfaces stabilize temperatures across the pack, while simple air paths manage short, high-power runs with lower complexity. Charging infrastructure at the circuit and diagnostics that monitor state-of-health help teams plan thermal cycles between sessions. Proper thermal management during charging also shortens cool-down windows and preserves battery life, which affects maintenance scheduling and modular pack swaps.

Motors and powertrain thermal management

Motors and associated powertrain electronics experience concentrated heat during repeated high-load laps. Heat conduction paths from stator and inverter assemblies to dedicated heat sinks, combined with airflow across fins or radiators, reduce thermal throttling. Consider modular powertrain housings that allow quick replacement and facilitate preventive maintenance. Regenerative braking systems must be coordinated with thermal limits so that returned energy does not exacerbate inverter or battery heating. Diagnostics embedded in the drivetrain can trigger mapped derating strategies before components exceed safe temperatures, preserving reliability without unexpected shutoffs.

Telemetry, diagnostics, and acoustics

Real-time telemetry and onboard diagnostics are critical to active cooling strategies. Telemetry streams for cell temperatures, motor winding heat, inverter junction temps, and inlet/outlet airflow allow engineers to adjust cooling tactics session-to-session. Acoustic monitoring helps detect abnormal fan behavior or rattling ducts early, improving safety and reducing maintenance burden. Combining thermal maps with lap-by-lap telemetry enables predictive cooling—raising fan speeds or opening vents only when needed—reducing unnecessary power draw and maintaining quiet operation where track rules limit noise.

Safety, regulations, and infrastructure

Cooling and airflow implementations must meet safety and regulatory requirements for any venue. Designs should prevent loose components, avoid exposed hot surfaces, and maintain fire containment strategies around battery enclosures. Track infrastructure—such as pit-side charging and cooling rigs—affects strategy choices; some circuits provide conditioned air or electrical hookups that support liquid chillers, while others require self-contained systems. Compliance with local regulations on noise, emissions from ancillary equipment, and electrical safety is essential; document cooling system changes and diagnostics to demonstrate adherence during scrutineering.

Modularity, maintenance, and charging

Modularity simplifies thermal management across a fleet. Swappable battery modules and modular motor mounts let teams precondition components off-cart, reducing pit dwell time and easing maintenance cycles. Routine maintenance should include duct inspection, fan bearing diagnostics, and coolant checks where liquid systems are used. Charging protocols that stagger sessions and use thermal-aware charge algorithms reduce peak temperatures and extend component life. Planning maintenance intervals around thermal profiles, telemetry alerts, and regeneration behavior keeps lap performance consistent without excessive overhaul costs.

Conclusion Sustained high-power laps demand a systems-level approach that blends directed airflow, active cooling, and data-driven control. Integrating battery and motor thermal strategies with telemetry and diagnostics preserves range, supports regeneration, and aligns with safety and infrastructure constraints. Emphasizing modularity and scheduled maintenance further ensures reliable lap-to-lap performance while meeting regulatory and acoustic considerations.