Cartoning Machine: Types, Operation, Selection, and Maintenance

A cartoning machine packs products into cartons efficiently, improving throughput and consistency across packaging lines. Whether you're running a small production cell or a high-speed manufacturing line, understanding how cartoning equipment works and which features matter can cut downtime, reduce waste, and ensure a professional finished package. This article explains core types, operation principles, typical use cases, selection advice, and upkeep best practices for industrial and semi-automatic cartoning machines.

What is a cartoning machine and why use one?

A cartoning machine automates placing products into cartons, folding and sealing the cartons as needed. They replace manual packing for repetitive tasks, boosting speed and uniformity while lowering labor costs and human error. Common carton formats include tuck-top, crash-lock base, and sleeve-style cartons, each requiring specific machine settings. Industries such as pharmaceuticals, cosmetics, food, and consumer goods rely on cartoning machines to meet regulatory labeling, hygiene, and presentation standards while maintaining high throughput.

How do cartoning machines operate?

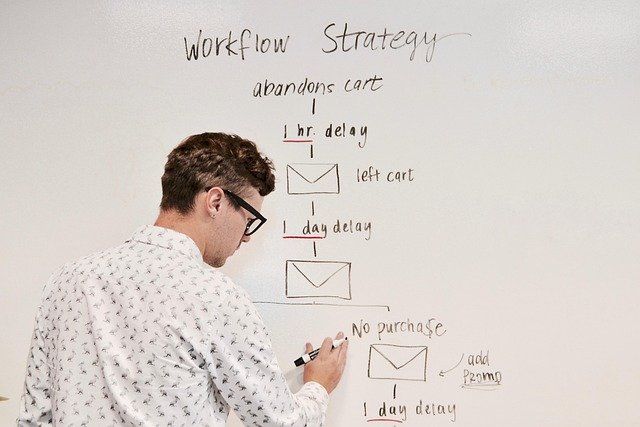

Most cartoning machines follow a common sequence: carton erecting, product insertion, carton closing, and sealing. Mechanisms vary—some use rotary systems for high-speed operation while others are intermittent for precise handling. Product insertion can be manual, semi-automatic with pick-and-place, or fully automatic with infeed conveyors and feeding systems. Closing and sealing may employ adhesive, tuck-flap, or hot-melt systems depending on carton design. Controls typically include PLCs and HMI panels for adjusting speeds, timing, and diagnostic alerts to simplify changeovers and troubleshooting.

What types and configurations are available?

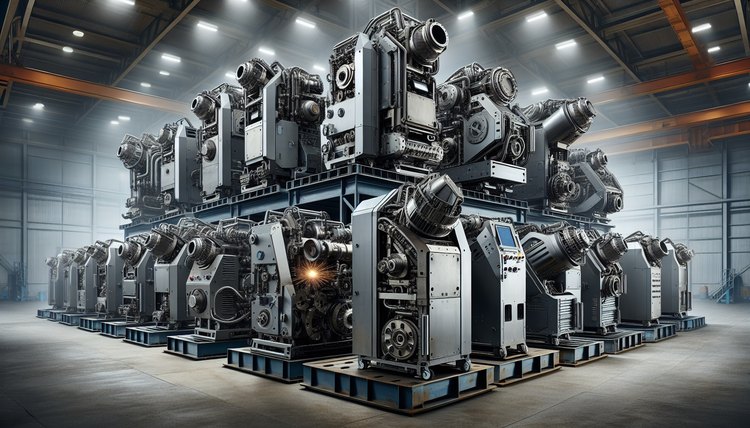

Cartoning machines come in several configurations: horizontal vs. vertical, intermittent vs. continuous (rotary), and benchtop vs. inline systems. Horizontal cartoners are common for single items and flow-wrap products; vertical cartoners suit multiple small items stacked into cartons. Modular designs allow integration with upstream and downstream equipment like fillers, labelers, and case packers. Material handling options—vibratory feeders, servo pick-and-place, or robotic arms—determine how well the machine handles fragile, irregular, or blister-packed products.

What to consider when selecting a cartoning machine

Choosing the right machine depends on production speed, carton type, product fragility, and available floor space. Evaluate changeover time, tooling cost, ease of cleaning, and regulatory needs (e.g., cleanroom compatibility for pharma). Consider automation level—semi-automatic units reduce capital cost but need more labor; fully automatic systems maximize throughput but require higher initial investment and integration. Check vendor support, spare parts availability, and whether local services can perform installation and maintenance in your area to minimize downtime.

Integration, safety, and quality control features

Modern cartoners include safety guards, interlocks, and emergency stops to meet workplace regulations. Integration with vision systems or sensors ensures correct product orientation, label presence, and fill accuracy, reducing customer complaints and recalls. Data logging and connectivity options (Ethernet/IP, OPC-UA) enable production monitoring and traceability. Evaluate how the machine will connect to your existing MES or SCADA systems to streamline line control and quality reporting without creating data silos or complex retrofits.

Maintenance, troubleshooting, and lifecycle considerations

Planned maintenance extends machine life and preserves uptime: routine lubrication, belt and guide inspections, belt tension checks, and periodic software updates are essential. Keep a small inventory of wear parts—seals, belts, sensors—to shorten repairs. Train operators on quick changeover procedures and basic troubleshooting (jam clearing, sensor recalibration). When considering lifecycle costs, include expected uptime, spare parts pricing, and potential obsolescence if a manufacturer discontinues support; modular machines with common electrical standards often offer longer practical service lives.

In summary, a cartoning machine is a core piece of packaging equipment that can transform efficiency and consistency for many industries. Selecting the right type involves balancing speed, flexibility, and total cost of ownership while ensuring the machine integrates with your line and meets safety and quality requirements. Proper maintenance and vendor support complete the equation, helping ensure reliable operation and a strong return on investment.