Comparing Soft-Top and Hardfold Roof Materials and Durability

This article compares soft-top and hardfold convertible roofs, focusing on material composition, expected longevity, and how roof mechanics influence maintenance and weatherproofing. It examines effects on noise, insulation, aerodynamics, storage, safety and resale value, and outlines routine care considerations and typical failure points.

Soft-top and hardfold convertible roofs present distinct advantages and maintenance needs based on their materials and mechanical designs. This article compares fabric-based soft-top systems and rigid hardfold or retractable roofs, emphasizing how material choices influence weatherproofing, noise levels, insulation, aerodynamic behavior, storage packaging, resale considerations, and overall safety. Understanding these differences helps owners and buyers evaluate trade-offs between simpler fabric upkeep and the mechanical complexity of hard panels.

How do soft-top materials perform?

Soft-top roofs generally use layered textiles: an outer weather-resistant fabric (commonly acrylic or coated canvas), a waterproof membrane, and an inner lining. Acrylic fabrics resist UV fading and breathe better, while coated vinyl is heavier but can be less expensive. Seams, adhesives, and the quality of the stitching determine long-term weatherproofing and vulnerability to leaks. Regular cleaning, fabric protectants, and inspected stitching extend service life; untreated fabric commonly shows abrasion, fading, and seam deterioration earlier than rigid panels.

How do drop-top and open roof designs differ?

Drop-top configurations emphasize compact stowage and lighter weight, often favoring soft-top materials for reduced packing volume. Open roof setups may include partial glass panels or larger retractable hard panels for a sunroof-like experience. Drop-top fabric can increase wind noise and reduce thermal insulation compared with rigid options, while open roof designs with glass or hard panels generally offer better climate control and quieter cabins. Aerodynamic stability depends on seals, panel fit, and how the roof integrates with the vehicle’s body.

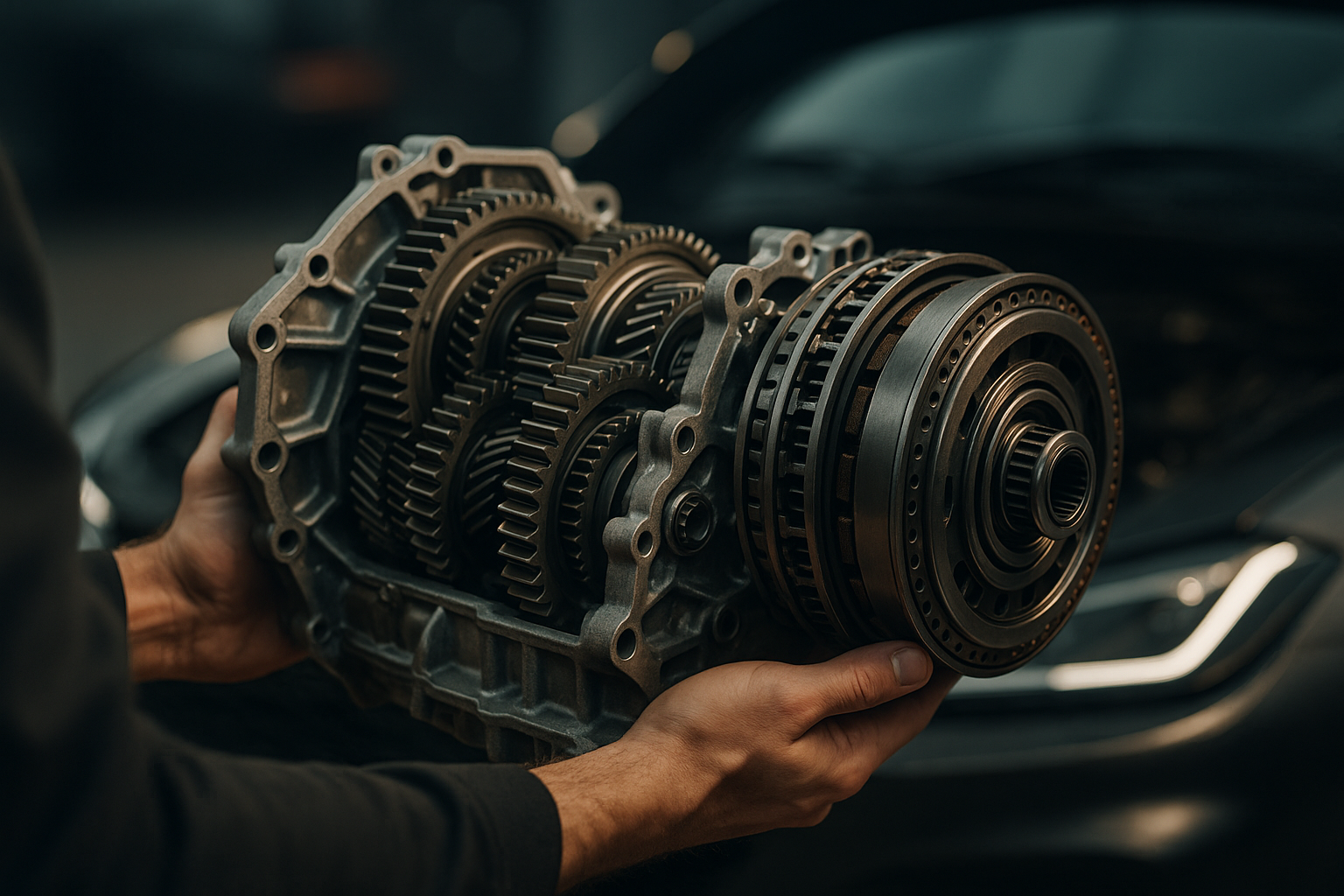

What materials are used in retractable hardfold roofs?

Retractable hardfold roofs combine metal panels (steel or aluminum), composites, and polymer trims with seals and drain channels. Panels add stiffness and insulation, improving security and noise control, and composites reduce weight and corrosion risk. However, the presence of hinges, actuators, and multi-part seals increases the number of components that can wear or misalign. Quality of materials, corrosion protection, and precision in assembly determine whether these systems remain durable over many years without expensive repairs.

How do roof mechanics affect safety and longevity?

Roof mechanics — hinges, latches, actuators, and seal systems — are central to both soft-top and hardfold performance. In soft-top frames, tensioning and frame integrity ensure good water shedding and aerodynamics. In hardfold systems, synchronized actuators and secure latching prevent panel flex, reduce cabin noise, and maintain structural stability. Regular inspection of mechanical linkages, drainage channels, and latch engagement reduces the risk of leaks, unexpected failures, or compromised occupant safety during operation.

What maintenance and weatherproofing are essential?

Maintenance varies by roof type: soft-top care focuses on fabric cleaning, UV protectants, seam inspections, and periodic water-repellent treatments. For hardfold roofs, attention to seals, hinge lubrication, actuator function, and corrosion prevention is important. Both systems benefit from covered storage to limit UV degradation and moisture exposure. Promptly addressing pinholes, torn seams, damaged seals, or malfunctioning actuators prevents water ingress, mold growth, and interior damage that can accelerate material degradation and depress resale value.

How do materials influence noise, insulation, aerodynamics, storage and resale?

Material choice directly affects cabin comfort and practicality. Hardfold roofs usually provide better thermal insulation and lower road or wind noise, which can make vehicles more attractive at resale. Soft-top systems are lighter and can allow smaller storage envelopes when stowed, but they often sacrifice some insulation and generate more wind noise at speed. Aerodynamic impacts depend on roof shape and seal quality; poor sealing increases buffeting and drag. Well-documented maintenance records and good condition of either roof type typically influence resale more than the roof choice alone.

Conclusion Selecting between a soft-top and a hardfold/retractable roof involves weighing material characteristics against expected maintenance and daily use. Soft-top roofs can be lighter and simpler to store but require diligent fabric care to remain weatherproof and attractive. Hardfold systems offer improved insulation, noise reduction, and perceived durability but introduce more complex roof mechanics that need periodic attention. Assessing local climate, storage options, and tolerance for mechanical upkeep helps determine which roof material and design best align with long-term durability and ownership expectations.