Design Approaches for Repairable and Upgradable Electronics

Designing electronics for repairability and upgradability requires attention to hardware, software, and lifecycle factors from the start. Practical design choices—covering processors and semiconductors, firmware practices, connectivity, sensors, and thermal systems—can extend device life, reduce waste, and simplify maintenance without compromising performance.

Designing electronics for repairability and upgradability requires attention to hardware, software, and lifecycle factors from the start. Practical design choices—covering processors and semiconductors, firmware practices, connectivity, sensors, and thermal systems—can extend device life, reduce waste, and simplify maintenance without compromising performance.

Processors and semiconductors: how to design for upgrades

Selecting processors and semiconductor packages with future-proofing in mind helps enable upgrades. Designers can favor socketed or replaceable processor modules where thermal and mechanical constraints allow, and choose standardized pinouts and power rails to ease substitution. Documenting electrical interfaces and maintaining compatibility matrices for semiconductors reduces the risk of obsolescence. Where fully integrated system-on-chip (SoC) choices are unavoidable, consider partitioning functions so performance-critical elements and general-purpose compute can be separated for later replacement.

Firmware and cybersecurity: maintainable software layers

Firmware strategy is central to upgradability and secure repair. Modular firmware design, clear bootloader separation, and support for field-upgradeable images allow non-invasive updates. Secure update mechanisms—signed images, rollback protection, and verification checks—preserve cybersecurity while enabling long-term maintenance. Exposing diagnostic interfaces for local or remote troubleshooting, combined with careful access controls, helps technicians apply fixes without exposing the device to undue risk. Maintainable release notes and versioned APIs are helpful for third-party service and component replacement.

Edge and connectivity: enabling modular expansion

Edge compute placements and connectivity choices affect how devices evolve. Designing clear expansion headers or standardized communication buses (USB-C, PCIe, M.2, or well-documented serial interfaces) lets additional modules add sensors, accelerators, or network options. Connectivity strategies should balance local edge processing and cloud integration to minimize the need for wholesale hardware replacement when workloads change. Providing configurable network stacks and modular drivers makes it easier to swap radios, add edge accelerators, or change connectivity layers as standards shift.

Sensors and displays: accessible replacement and calibration

Sensors and displays are common repair points; designing for access and calibration streamlines servicing. Use replaceable modules with standardized connectors and documented calibration routines so a technician can swap a sensor and apply calibration without full system rework. For displays, modular frames, accessible cable routes, and spare-part listings aid reparability. Include on-device or software-guided calibration tools to ensure replacement components meet performance expectations without needing specialized factory equipment.

Modularity and repairability: mechanical and electrical strategies

Mechanical and electrical modularity go hand in hand. Mechanical design that prioritizes captive fasteners, clear service panels, and labeled connectors reduces the risk of damage during repair. Electrically, adopting modular PCBs, daughtercards, and cable harnesses isolates subsystems so one failing element can be replaced rather than the entire assembly. Standardizing parts—fasteners, screws, connectors—across product lines reduces spare-part complexity. Documentation, repair manuals, and clear part numbering facilitate local services and third-party repair shops in your area.

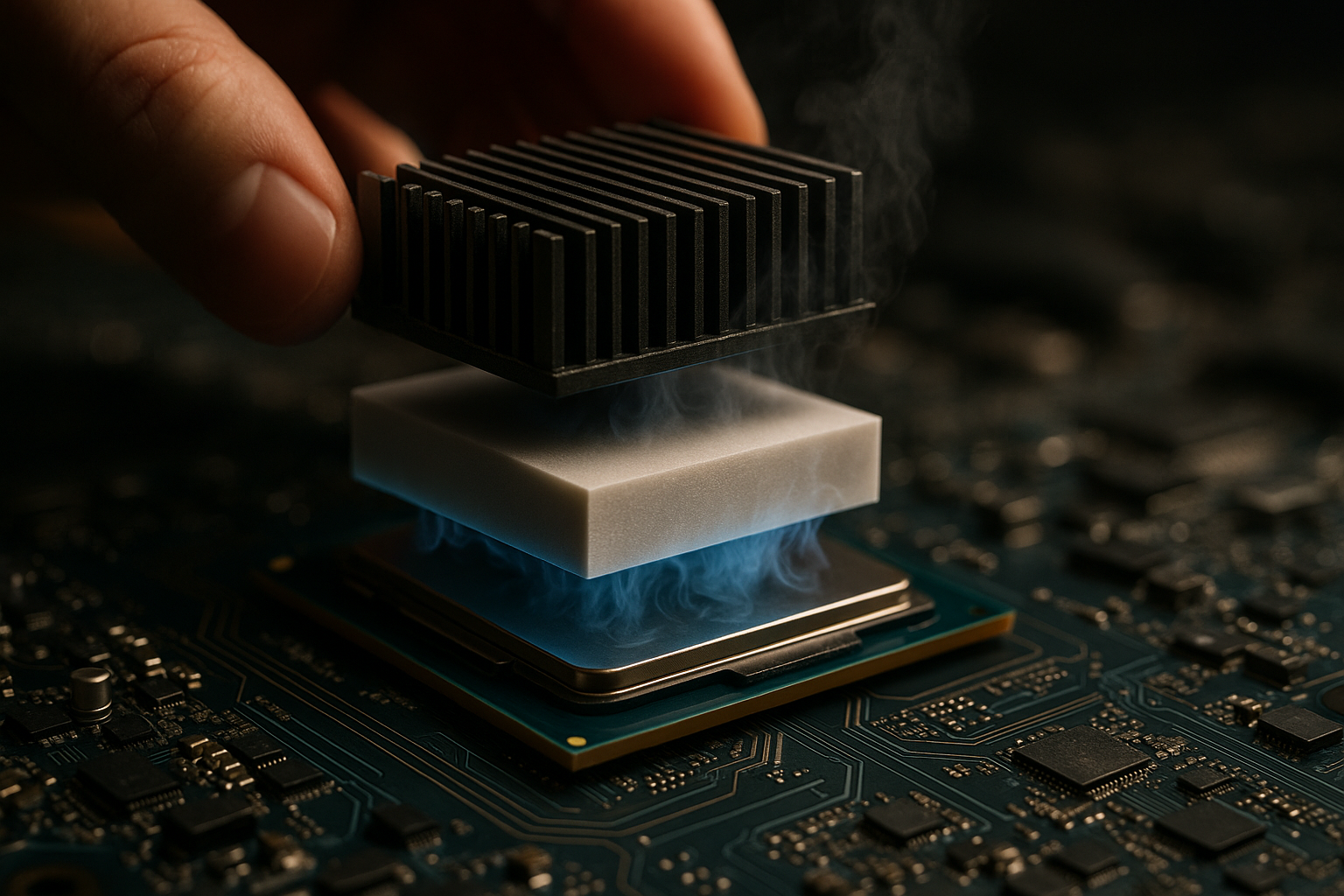

Thermal and sustainability: longevity considerations

Thermal management affects both reliability and upgradeability. Designing adequate cooling margins, removable heat sinks, and modular airflow paths allows higher-performance modules to be added later without redesigning the entire chassis. Use thermal interfaces and mechanical mounting solutions that support repeated service cycles. Sustainability considerations—material selection, recyclability, and access to spares—should be integrated with thermal strategies to ensure that end-of-life handling and component replacement minimize environmental impact while maintaining device function.

Design for repairability and upgradability improves resilience across hardware and software layers. Combining processor and semiconductor planning with modular firmware, secure update paths, flexible connectivity, accessible sensors and displays, and thoughtful thermal design reduces waste and supports longer device lifecycles. Clear documentation and standardized mechanical and electrical interfaces allow local services and third-party technicians to perform maintenance and upgrades without risking device integrity. When these design approaches are applied consistently, they help create electronics that adapt to evolving requirements while supporting sustainability and practical field maintenance.