DIY Pitfalls: Why Improper Chip Treatments Fail

Many vehicle owners attempt DIY fixes when a small windshield chip appears, hoping to avoid inconvenience or cost. While some kits can temporarily improve appearance, improper preparation, wrong materials, or missed damage beneath the surface often mean the repair fails or the pane weakens, creating safety and visibility issues down the line.

A single small chip can feel urgent but manageable, and DIY kits promise fast fixes. The reality is that a windshield is an engineered safety component: laminated glass, embedded interlayers, and precise optical properties all matter. When a treatment is applied incorrectly—contaminated surfaces, incomplete resin flow, or improper curing—the result can be a cosmetically improved spot that still spreads into a structural crack or reduces optical clarity.

How do windshield chips turn into cracks?

Chips commonly start from stone strikes or road debris and damage only the outer layer of the laminated windshield. Left untreated or treated poorly, stresses from temperature changes, road vibration, and further impacts cause micro-fractures to propagate. Tiny air pockets, moisture, or trapped dust at the damage site act as stress concentrators. Over time these weaken the immediate area, turning a localized chip into a radial crack or star pattern that compromises the pane’s integrity and the vehicle’s crash performance.

Why resin and adhesive repairs sometimes fail

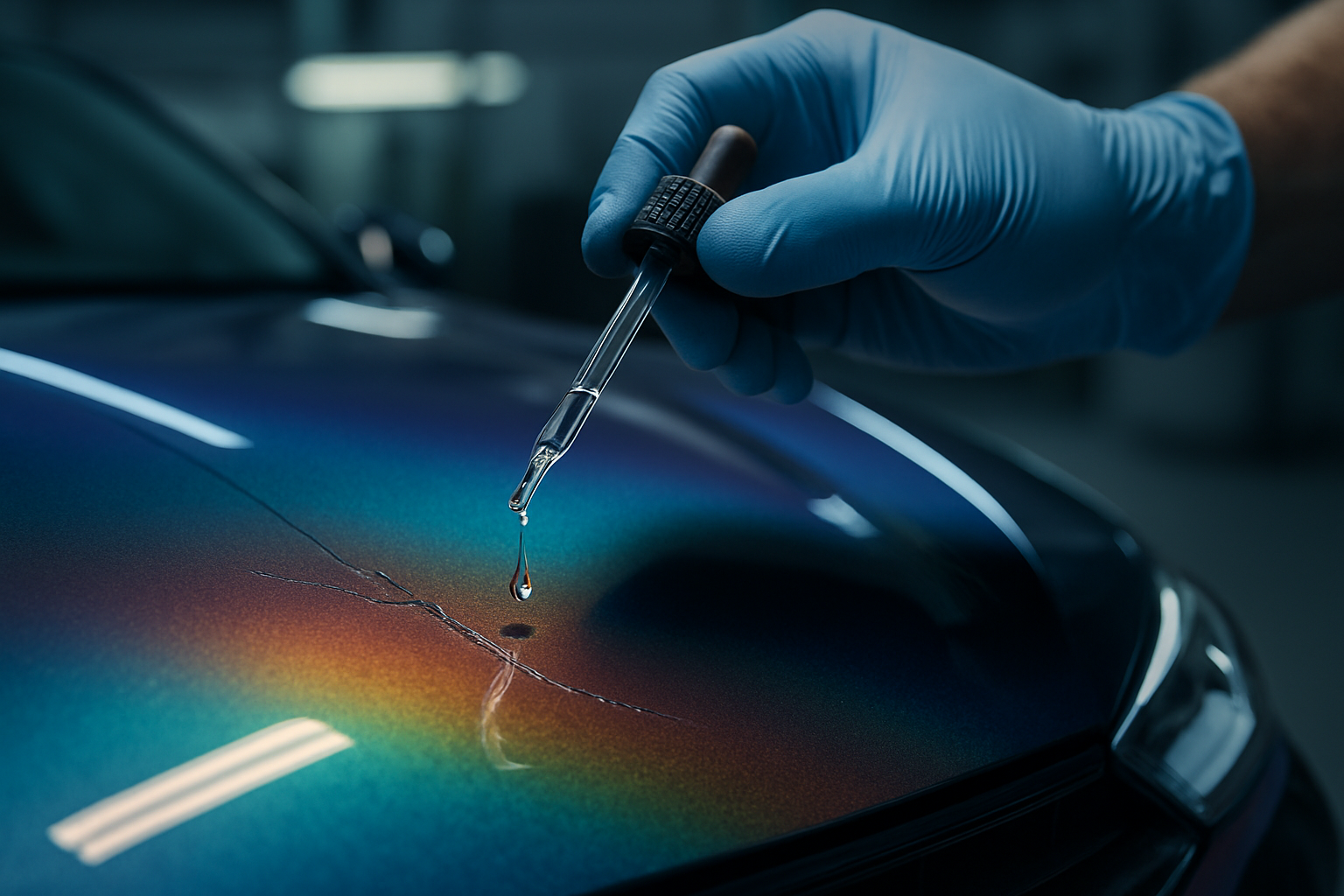

Repair resins and adhesives are formulated for specific fracture patterns and glass types. Failure often stems from using the wrong viscosity resin, poor injection technique, or inadequate curing under the correct light or pressure conditions. If resin doesn’t fully penetrate the fracture path, voids remain and visual defects persist. Adhesives that don’t match original specifications may lack bonding strength or optical clarity, so the pane may look improved but still performs poorly under stress.

Common DIY mistakes that worsen cracks

A frequent DIY mistake is skipping surface preparation: grease, silicone, and road grime prevent proper resin adhesion. Overpressurizing an injection can force contaminants deeper into cracks. Inadequate curing—either by time or incorrect light source—leaves resin soft and prone to shrinkage, which reintroduces gaps. Using a kit on a chip already connected to a long crack or a damaged interlayer can accelerate failure; some damage requires full replacement, not patching.

Can DIY or mobile fixes affect pane calibration?

Modern vehicles sometimes require windshield-related calibration for driver-assistance systems after glass work. A rushed mobile fix or an imprecise replacement can misalign cameras or sensors mounted in or near the windshield. Even when repair preserves the glass, incorrect adhesive selection or uneven bonding can change optical paths or sensor mounting points. Technicians who understand calibration steps and follow manufacturer procedures reduce the risk of degraded system performance.

Insurance, replacement options, and visibility risks

Insurance policies vary in how they handle chip repair versus full replacement, and some insurers prefer repair to avoid the higher cost of replacement. However, a failed DIY repair that later requires replacement can affect claims and coverage. Visibility is another factor: improper repairs often leave distortions or refractive inconsistencies that distract drivers in direct sunlight or at night. Where safety systems rely on a clear optical path, compromised visibility can reduce effectiveness even if the pane remains intact.

Maintenance, safety practices, and technicians’ role

Routine maintenance—prompt inspection after a chip, keeping the area clean, and avoiding rapid temperature changes—helps prevent propagation. Qualified technicians assess depth, interlayer damage, and impact location to determine whether resin repair is appropriate or full replacement is safer. Professional repair uses controlled injection tools, proper resins, and curing protocols; replacement follows OEM adhesive and calibration practices. That expertise preserves structural performance and reduces the chance of repeated failures.

In summary, DIY chip treatments can appear convenient but carry risks: incomplete resin penetration, contamination, incorrect adhesives, and missed calibration needs can all lead to failure. Understanding these pitfalls helps owners choose the right path—professional assessment, appropriate repair, or replacement—to maintain visibility and safety without relying on temporary fixes.