Embedding digital twin exercises into operator development plans

Integrating digital twin exercises into operator development plans strengthens practical learning by pairing simulation with real-world tasks. This approach supports automation and robotics literacy, informs maintenance strategies, and helps structure competency assessments for upskilling and reskilling programs.

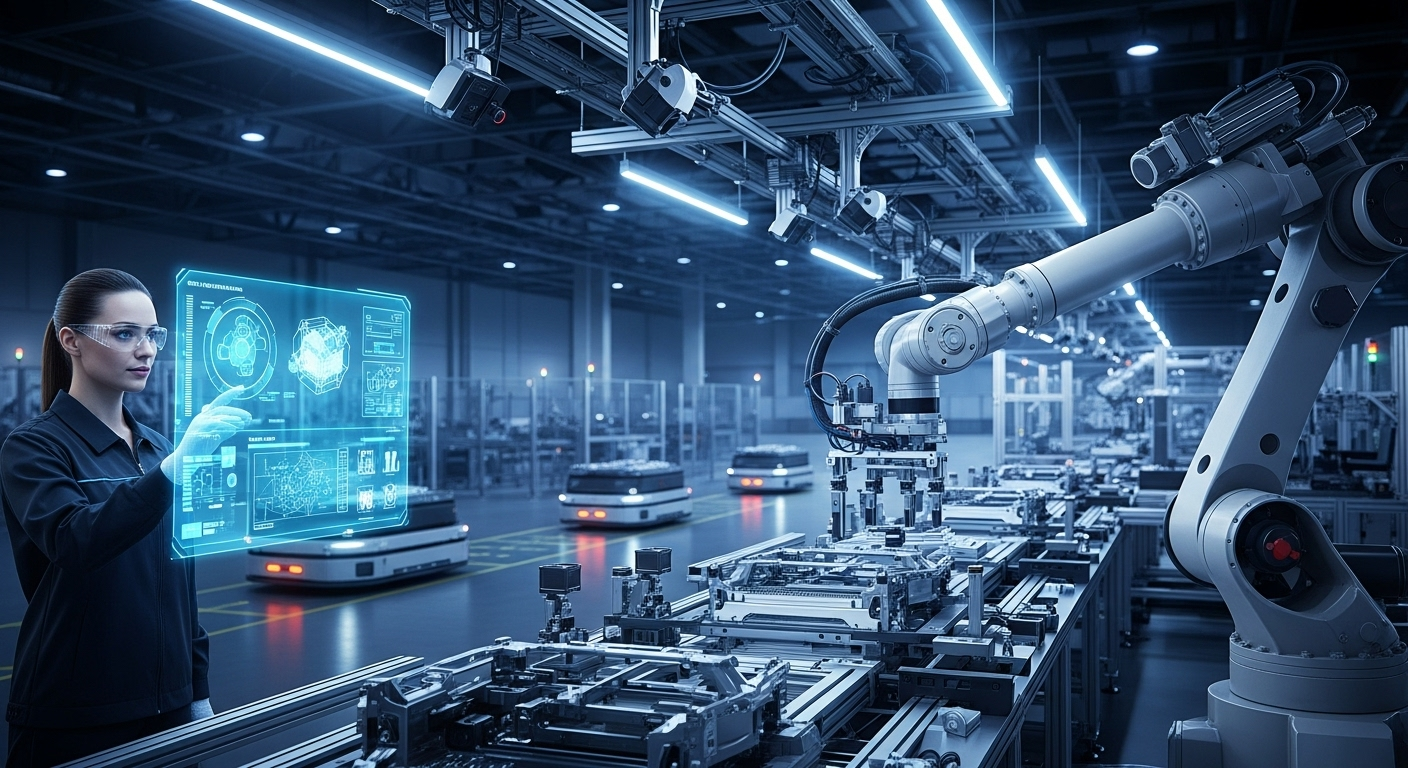

Embedding digital twin exercises into operator development plans requires deliberate alignment between simulated scenarios and on-the-floor responsibilities. A digital twin—a virtual replica of equipment, processes, or entire production lines—enables operators to practice responses to faults, optimize workflows, and build familiarity with automation and robotics systems without putting actual assets at risk. When planned correctly, exercises can support continuous learning, measurable competency, and safer operations while providing data to guide maintenance and predictive strategies.

Automation and digital twin exercises

Digital twins allow operators to interact with automated systems in a controlled environment. Exercises can replicate PLC logic, conveyor interactions, robotic pick-and-place sequences, and automated material flows so operators learn timing, interlocks, and exception handling. Incorporating automation-focused scenarios helps trainees understand cause-and-effect relationships and the limitations of automated control, which improves troubleshooting and decision-making under pressure. Use scenario variation to simulate common faults, sensor failures, and differing production mixes so operators can practice intervention steps before encountering similar events on the plant floor.

Upskilling and reskilling pathways

Design digital twin practicums to align with defined career pathways for both upskilling and reskilling. For upskilling, create layered modules that move from basic monitoring to advanced process tuning and analytical tasks. For reskilling, map core competencies in safety, control systems, and data interpretation to practical simulations that reinforce transferable skills. Tracking completion, time-to-competency, and assessment results helps learning teams adapt curricula and supports HR and workforce planning for evolving roles around automation and robotics.

Simulation, practicum, and remote training

Simulation-based practicums let operators rehearse hands-on tasks without occupying physical equipment, and digital twins support remote training for distributed teams. Remote sessions can combine live instructor guidance with recorded scenario playbacks, allowing learners to experience complex events asynchronously. Maintain realistic HMI layouts, alarm behavior, and timing in simulations so that practicum exercises translate effectively into real-world proficiency. Blended delivery—combining on-site shadowing with remote simulation—reduces downtime impact while broadening access to developer plans across locations.

Competency, assessment, and measurable outcomes

Embed clear competency frameworks into each digital twin exercise so assessments target observable behaviors and technical outcomes. Use objective metrics such as task completion time, error rates, alarm response accuracy, and corrective action quality to evaluate performance. Pair automated logging from the twin with structured debrief sessions to provide qualitative feedback. By linking assessments to certification levels or badges, organizations can document operator readiness for specific responsibilities involving automation, predictive maintenance tools, and robotics interfaces.

Maintenance and predictive use cases

Digital twins can mirror equipment degradation modes and failure progressions, making them valuable for maintenance training and predictive practice. Exercises can simulate bearing wear, seal failures, or control drift and require operators to interpret diagnostic data, schedule maintenance, or execute temporary mitigations. Integrating condition-monitoring data into twin scenarios teaches operators how predictive alerts map to physical interventions, and helps maintenance teams coordinate with operations to minimize downtime while preserving safety and product quality.

Safety, robotics, and operational readiness

Safety should be integral to every exercise. Simulate hazardous scenarios, emergency stops, interlock failures, and safe robot-human collaboration zones so operators gain muscle memory for protective actions. Robotics-focused exercises must emphasize safe programming checks, collaborative robot (cobot) boundaries, and recovery procedures after an unexpected stop. Operational readiness drills using digital twins can rehearse shift turnovers, multi-asset coordination, and outage responses without risking personnel or equipment, reinforcing a culture of safety and preparedness.

Conclusion

Embedding digital twin exercises into operator development plans bridges virtual learning and physical operation by providing repeatable, measurable, and safe practice. When exercises are aligned to competency frameworks and include realistic automation, maintenance, safety, and robotics scenarios, they support upskilling and reskilling while improving assessment quality and operational resilience. Thoughtful integration of simulation and remote practicum elements ensures training is scalable and relevant across facilities and roles.