Factory Jobs: Roles, Skills, and Production Trends

Factory work covers a wide range of roles in production settings where materials and components are transformed into finished goods. This article outlines common factory roles, typical production processes, worker skills, and aspects of manufacturing in Japan, and it explains what applicants and employees can generally expect. It does not list specific current job openings or provide location-specific vacancy information.

Factory roles and typical duties

Factory roles vary from entry-level production operators to machine technicians and supervisory staff. Common duties include operating machinery, assembling parts, maintaining equipment, conducting quality checks, and following safety protocols. Many factories divide responsibilities across stages of a production line, so individual tasks can be repetitive but focused on consistent output and defect prevention.

Shift patterns, team sizes, and specialization depend on product type and automation level. In highly automated plants, roles emphasize machine oversight and programming, whereas in manual assembly settings, dexterity and attention to detail are more important. Health and safety training is typically part of onboarding.

How manufacturing processes shape production

Manufacturing processes — such as stamping, molding, machining, welding, and assembly — determine factory layout, throughput, and quality control needs. Process selection depends on volume, tolerances, and material choices. Continuous processes suit high-volume commodities, while discrete manufacturing fits varied, smaller-batch products.

Production planning, inventory control, and preventive maintenance are key to minimizing downtime. Lean manufacturing methods and quality systems (for example, standardized work and root-cause analysis) are widely used to reduce waste and improve consistency. Understanding the flow from raw material to finished product helps workers see how daily tasks contribute to overall output.

Working conditions faced by a factory worker

Working conditions can include shift work, exposure to noise, physical demands, and repetitive tasks. Employers commonly provide personal protective equipment (PPE), safety training, and ergonomics assessments to reduce risks. Variation in temperature, chemical exposure, or heavy lifting depends on the industry and production technology.

Many factories have formal procedures for reporting hazards and near-misses, and regulatory frameworks set minimum standards for occupational safety. For prospective workers, reviewing employer safety records, training programs, and shift arrangements can clarify expectations before accepting a position. This article does not provide specific employer safety ratings or job listings.

Japan’s manufacturing sector and production practices

Japan has a long-established manufacturing sector characterized by precision engineering, automotive production, electronics, and strong supplier networks. Emphasis on continuous improvement (kaizen), quality management, and skilled craftsmanship influences factory organization and training. Small and medium manufacturers often collaborate within regional clusters supplying larger assemblers.

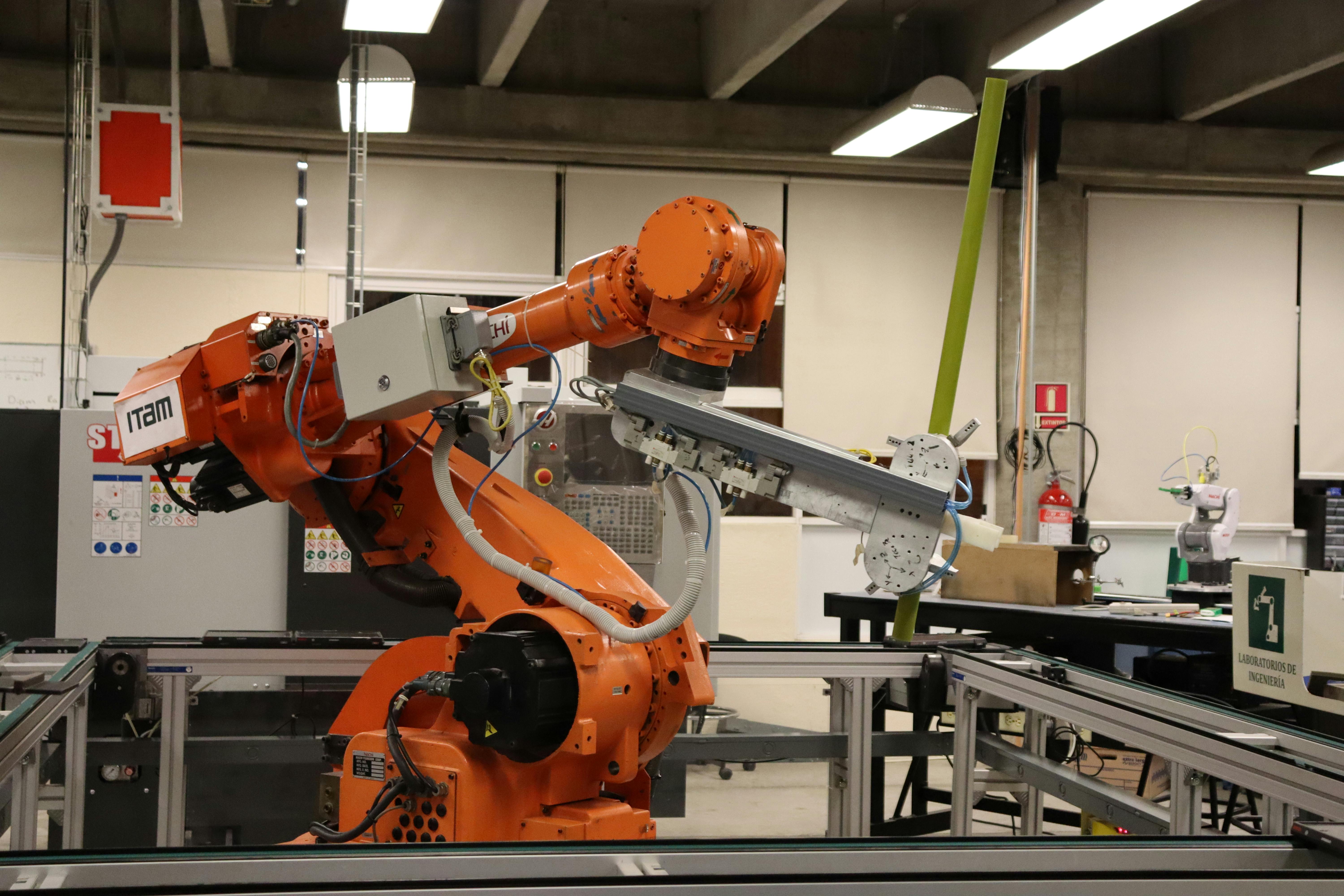

The balance between automation and skilled labor varies by industry. In some advanced plants, robots perform high-precision tasks while human workers handle inspection, problem-solving, and final assembly. Economic and demographic factors also shape workforce availability and training initiatives in Japan’s manufacturing regions.

Skills, training, and career pathways in production

Key skills for factory positions include mechanical aptitude, attention to quality, basic troubleshooting, and teamwork. Technical training can be acquired through vocational schools, apprenticeships, or on-the-job programs. Familiarity with reading technical drawings, using measuring tools, and following standardized procedures is frequently valued.

Career pathways often move from operator roles to technician, process improvement, or supervisory positions. Additional certification in areas like welding, CNC operation, or quality control can open advancement opportunities. Employers may offer internal training and external course support to develop required competencies.

Conclusion

Factory jobs are a broad and varied category encompassing manual assembly, machine operation, technical maintenance, and supervisory roles. Production practices, worker responsibilities, and training differ by industry and region, with Japan offering notable examples of high-quality manufacturing practices. This article provides general information and does not present specific job vacancies or location-based listings; readers seeking openings should consult official employer sites or established job platforms for verified opportunities.