Guide to Insulation Sheets: Types, Selection, and Installation

Insulation sheets are a practical way to improve a building’s thermal performance, reduce energy use, and increase comfort year-round. Available in multiple materials and thicknesses, they suit walls, roofs, floors, and specialist applications. This guide explains common types, how they work, selection criteria, safe installation, and maintenance to help you make informed decisions.

What are insulation sheets?

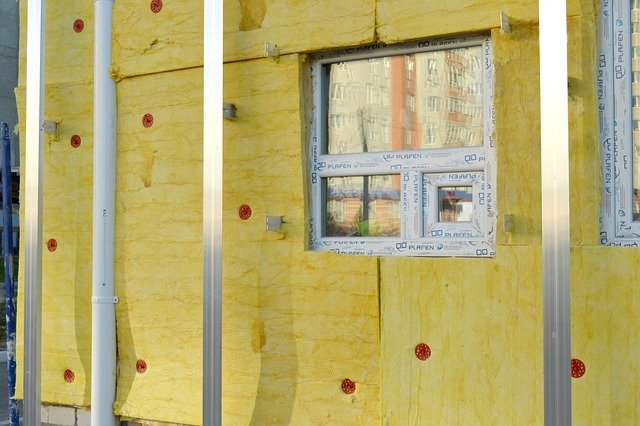

Insulation sheets are rigid or semi-rigid panels made from materials designed to resist heat flow. Unlike loose-fill or batt insulation, sheets provide a stable, continuous layer that is easy to cut and fit to flat surfaces. Common uses include external wall insulation, underfloor layers, roof decks, and cavity fills where a compact, durable material is required. Their form factor makes them particularly useful where space is limited or where a neat, uniform installation is desired.

What types of insulation sheets are available?

Several materials are commonly manufactured as sheets. Expanded polystyrene (EPS) is lightweight and economical for many structural uses. Extruded polystyrene (XPS) offers higher compressive strength and moisture resistance, good for below-grade or under-slab use. Polyisocyanurate (PIR/PUR) boards have higher thermal performance per inch and are widely used for walls and roofs. Mineral wool boards deliver good fire resistance and sound insulation. Reflective foil-faced boards reduce radiant heat transfer in some assemblies. Each material carries performance trade-offs in R-value, moisture tolerance, fire behavior, and cost.

How do insulation sheets perform (R-value and thermal properties)?

Performance is commonly expressed as R-value, which indicates resistance to heat flow; higher values mean better thermal resistance. R-value depends on both the material and thickness: for example, PIR typically delivers a higher R-value per inch than EPS. Thermal bridging, air gaps, and compression reduce effective performance, so continuous coverage and properly sealed joints are important. Some boards also incorporate facings, like foil or vapor-control layers, which can improve performance when matched to the building’s moisture and ventilation strategy.

How to choose the right insulation sheet for your project?

Begin by identifying the application—roof, wall, floor, or foundation—then consider the required thermal performance, moisture exposure, and fire-safety requirements. For below-slab or high-moisture areas, choose boards with good compressive strength and low water absorption (e.g., XPS). For limited cavity depth where high R-value is needed, PIR may be appropriate. If fire performance or acoustic control matters, mineral wool is often preferred. Always check compatibility with existing assemblies, local building codes, and whether additional vapor barriers or breather membranes are needed.

How to install insulation sheets safely and effectively?

Proper installation preserves performance. Measure and cut boards accurately to minimize gaps; stagger joints where possible and seal seams with compatible tape or foam to reduce air leakage. Use mechanical fasteners or adhesive specified for the material and substrate; follow manufacturer guidance for fixing patterns and edge clearances. Ensure contact with cladding or finishes is compatible—some materials must be separated from certain finishes by a ventilation gap. Wear gloves, protective eyewear, and a dust mask when cutting boards, and follow site safety regulations regarding fire and handling.

Sustainability, maintenance, and local services in your area

Consider the environmental profile: manufacturing impacts, recyclability, and embodied carbon differ by material. Mineral wool and some polyiso products may have recycled content; foam boards vary in recyclability. Inspect insulation periodically for moisture intrusion, compression, or physical damage, and replace compromised sections promptly to maintain thermal performance. For supply and installation, consult local services such as certified insulation installers, building envelope contractors, or energy auditors to assess needs and confirm compatibility with local codes. Ask providers about product datasheets, warranty terms, and proof of certification.

Conclusion

Insulation sheets offer a flexible, space-efficient solution for improving thermal comfort and reducing energy consumption across many building elements. Choosing the right type depends on application, moisture exposure, fire safety, and required thermal performance; proper installation and maintenance are key to preserving benefits over time. Working with knowledgeable local services and checking technical specifications will help ensure the best outcome for your project.