How routine inspections prevent cold-weather breakdowns

Routine inspections are a key prevention measure that help household heating systems run reliably through cold months. A planned inspection catches wear, clogged filters, calibration issues and combustion problems before they cause a breakdown, protecting comfort and safety. Regular checks also support efficiency and can lower the likelihood of emergency repair calls during peak demand.

How does inspection protect furnaces and boilers?

Routine inspection of a furnace or boiler reveals early signs of wear such as cracked heat exchangers, corroded components, or failing ignition systems. Technicians check burners, pilot assemblies, and pressure elements to ensure combustion and heat transfer are operating correctly. Catching small issues before they escalate reduces the risk that either system will fail on the coldest nights, and helps extend the appliance’s service life while maintaining consistent indoor temperatures.

Why check thermostat and calibration?

A thermostat that isn’t calibrated correctly can cause short-cycling, inefficient runtimes, or insufficient heating even when equipment is healthy. During an inspection a technician will verify settings, test accuracy, and inspect wiring or programmable schedules. Proper calibration influences overall system efficiency and comfort by ensuring the furnace or boiler responds correctly to setpoints. It also prevents unnecessary wear from frequent on/off cycles driven by misread temperature sensors.

How do filters and airflow affect efficiency?

Clogged or improperly sized filters restrict airflow, which forces the system to work harder and reduces heat delivery. Inspections include checking filter condition and recommending replacement intervals based on actual use and environmental factors. Technicians also evaluate airflow through vents and returns to identify blockages or imbalances. Maintaining clean filters and unobstructed airflow supports heat transfer efficiency, reduces energy consumption, and lowers the chance of overheating or flame rollout situations.

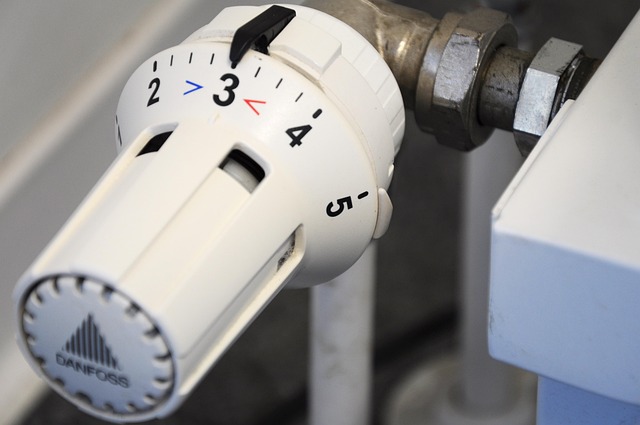

What should be inspected in ductwork and radiator systems?

Inspection of ductwork looks for leaks, disconnected seams, insulation gaps, and areas that impede airflow. Sealed, well-insulated ducts preserve conditioned air and prevent uneven heating. For radiator or hydronic systems, checks include valve operation, bleed points, pressure, and signs of hidden leaks or corrosion. Addressing these issues during routine servicing avoids cold spots, pressure loss, and the need for more extensive repair work during freezing weather.

How are combustion and safety risks addressed?

A core element of heating inspection is verifying safe combustion and venting. Technicians examine burner settings, flame patterns, exhaust flue connections, and combustion air supply to reduce carbon monoxide and combustion instability risks. Safety controls, such as limit switches and pressure relief valves, are tested to confirm they function under fault conditions. Properly executed combustion testing and safety checks are essential for protecting occupants and meeting code or manufacturer recommendations.

When to schedule servicing, repair, and consider zoning?

Most manufacturers and service professionals recommend annual inspections before the heating season. During a routine visit, servicing tasks—cleaning burners, replacing filters, calibrating thermostats, lubricating motors, and tightening electrical connections—can be completed to minimize repair needs. Homeowners evaluating comfort issues may also consider zoning adjustments or adding radiator balancing to optimize heat distribution. Local services can advise on system capabilities and whether zoning or minor repairs provide better year-round efficiency.

Conclusion

Systematic inspections reduce the chance of cold-weather failures by identifying degraded components, restoring proper calibration, ensuring safe combustion, and improving airflow and efficiency. Regular servicing preserves performance and comfort while addressing safety concerns before they become emergencies. Scheduling periodic checks with qualified technicians supports predictable operation during winter without relying on reactive repairs or last-minute fixes.