Insulation Sheets: A Practical Guide for Homes and Buildings

Insulation sheets are a straightforward, effective way to control heat flow, reduce energy bills, and improve comfort in residential and commercial buildings. Available in a range of materials and thicknesses, these panels serve different needs from roof and wall cavities to underfloor and external cladding applications. This guide explains types, performance factors, selection tips, and installation best practices so you can make informed decisions for your project.

What are common types of insulation sheets?

Rigid foam boards are among the most widely used insulation sheets. Polyisocyanurate (polyiso) offers a high thermal resistance per inch, making it suitable where space is limited. Expanded polystyrene (EPS) and extruded polystyrene (XPS) are durable, moisture-resistant options often used for below-grade or exterior applications. Mineral wool boards (rock wool) provide both thermal and acoustic insulation plus good fire resistance. Reflective foil-faced boards can reduce radiant heat transfer in ceilings and lofts.

Different sheet materials bring different properties: thermal performance (R-value), water resistance, compressive strength, and fire behavior. When comparing types, consider the installation location (interior, exterior, below slab), exposure to moisture, and whether you need a vapor or air barrier. Manufacturers usually provide R-value per inch and guidance on compatible substrates and adhesives.

How do insulation sheets improve energy efficiency?

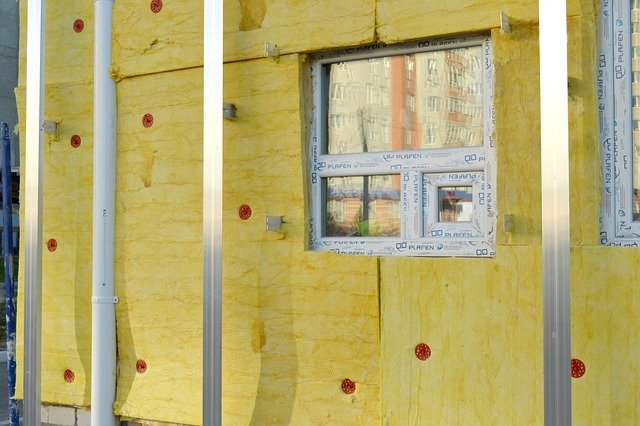

Insulation sheets limit conduction and, in some cases, convective air movement through building envelopes. Higher R-values slow heat transfer, keeping indoor spaces warmer in winter and cooler in summer. In practice, continuous exterior insulation—sheets wrapped over framing or sheathing—reduces thermal bridging where studs or metal fasteners bypass cavity insulation, delivering better whole-wall performance than cavity insulation alone.

Beyond pure thermal resistance, appropriate sheet selection can reduce HVAC cycling, lower peak loads on heating and cooling systems, and improve overall building airtightness when combined with good sealing practices. For retrofit projects, adding insulation sheets to walls or rooflines is often one of the fastest ways to improve energy performance with minimal interior disruption.

How to choose the right insulation sheet for your project?

Start by identifying the primary performance priorities: thermal resistance, moisture management, fire safety, or sound control. For example, below-grade or foundation uses favor XPS or EPS for moisture resistance, while high R-value per inch needs may lead to polyiso. If fire performance is a key concern, mineral wool or treated boards may be preferable because of better non-combustibility characteristics.

Also check compatibility with local building codes and the substrate (concrete, timber, metal). Consider installation method—mechanical fixings, adhesives, or both—and whether you’ll need tapered or profiled boards for drainage or falls. When in doubt, consult local services or certified installers in your area who can assess site-specific conditions, recommend suitable products, and ensure compliance with ventilation and vapor control requirements.

Installation tips and maintenance for insulation sheets

Proper installation impacts both performance and longevity. For continuous exterior applications, stagger joints and tape or seal seams to create a continuous barrier. When installing on internal walls or between rafters, avoid compressing the board and maintain recommended clearances to HVAC ducts or heat sources. When adhesives are used, follow manufacturer cure times and ensure surfaces are clean and dry.

Maintenance is generally minimal: check for signs of moisture intrusion, mechanical damage, or degraded seals around penetrations periodically. For exterior installations, ensure cladding or protective layers remain intact to prevent UV or moisture damage. If you hire professional installers, request documentation of product specifications and warranties so you can track expected service life and replacement intervals.

Sustainability and environmental considerations

Insulation sheets can contribute to lower operational carbon by reducing energy use. However, embodied carbon and end-of-life recycling vary by material. Mineral wool and certain rigid foams have different manufacturing footprints and recyclability. Look for products with environmental product declarations (EPDs), recycled content, or third-party certifications to compare lifecycle impacts. In some markets, manufacturers offer take-back or recycling programs for scrap offcuts; check availability with suppliers or local services.

Consider overall building strategy: pairing insulation sheets with air-sealing, efficient windows, and controlled ventilation often yields the best energy and comfort outcomes. Where possible, prioritize durable materials that maintain R-value over time and minimize moisture-related degradation.

Conclusion

Insulation sheets are versatile components for improving thermal performance, comfort, and durability in buildings. Selecting the right material requires balancing thermal needs, moisture exposure, fire safety, and installation constraints. Proper planning, attention to seams and interfaces, and coordination with local services or qualified installers will help ensure the insulation delivers long-term energy and comfort benefits without unintended moisture or compatibility problems.