Insulation Sheets: Types, Selection, and Best Practices

Insulation sheets are a versatile component in modern construction and retrofit projects, offering a simple way to reduce heat transfer, cut energy bills, and improve comfort. Available in many materials and thicknesses, these sheets are used in walls, roofs, floors, and HVAC ductwork. This article explains common types, how to choose the right sheet for a project, installation tips, and longevity considerations so homeowners, contractors, and specifiers can make informed decisions.

What are insulation sheets?

Insulation sheets are flat panels designed to resist heat flow through conduction, convection, and radiation. They can be rigid boards, semi-rigid panels, or flexible sheets depending on material and application. Typical uses include cavity insulation in walls, under-slab thermal layers, roof insulation, and as liners for mechanical systems. Their performance is commonly expressed by an R-value (thermal resistance) per unit thickness and by properties such as moisture resistance, compressive strength, and fire performance, which influence where each product is best applied.

Common materials and performance

Several materials are used for insulation sheets, each with distinct performance traits. Expanded polystyrene (EPS) is lightweight, cost-effective, and good for compressive loads. Extruded polystyrene (XPS) offers higher moisture resistance and compressive strength. Polyisocyanurate (PIR) and polyurethane (PUR) foam sheets provide high R-values per inch, making them space-efficient. Mineral wool boards are non-combustible and excel at sound absorption as well as thermal resistance. Choice depends on factors like required R-value, exposure to moisture, structural loads, and fire classification.

Thermal ratings and R-values explained

R-value measures a material’s resistance to heat flow; higher R-values mean better thermal performance. Insulation sheets are rated per inch, so thicker boards generally deliver higher R-values, but material type matters more than thickness alone. For example, PIR boards typically have higher R/inch than EPS. When designing assemblies, consider whole-system performance: thermal bridging through studs, joints between sheets, and continuity of the vapor barrier can reduce effective insulation. Also note that real-world conditions (moisture, compression, aging) can lower rated R-values over time.

Choosing the right sheet for your project

Selecting the right insulation sheet requires balancing thermal needs, budget, space constraints, and environmental conditions. For below-grade and floor applications, choose materials with strong moisture resistance and compressive strength like XPS or high-density EPS. For confined cavities where space is limited, high R/inch options such as PIR may be appropriate. In areas with stringent fire codes, mineral wool or appropriately rated foam with fire barriers could be necessary. When sourcing materials, check technical datasheets for R-values, compressive strength, water absorption, and relevant code approvals, and consult local services or suppliers in your area for availability and guidance.

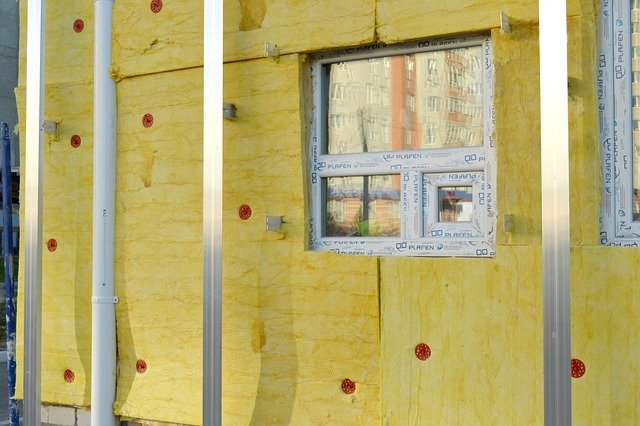

Installation tips and best practices

Proper installation is essential to achieve expected performance. Cut sheets carefully to fit tightly against framing and other sheets to minimize gaps; use compatible sealants or tapes to create a continuous thermal barrier. Avoid compressing insulation, which reduces effective R-value. For exterior applications, provide appropriate weather and vapor control layers as specified by product instructions. When adhering sheets, use adhesives recommended by the manufacturer and allow for expansion where products are sensitive to temperature. Safety precautions — such as protective gear and ventilation — are important when cutting or handling fibrous or foam materials.

Sustainability, durability, and maintenance

Consider lifespan, environmental impact, and end-of-life options when selecting insulation sheets. Mineral-based products are often recyclable and non-combustible, while some foam boards have higher embodied carbon but deliver long-term operational energy savings due to higher R-values. Durability depends on moisture control and mechanical protection; exposed sheets should be shielded from UV and physical damage. Periodic inspection in accessible areas can identify compression, moisture staining, or damaged joints that reduce performance. Choosing products with manufacturer warranties and documented longevity can provide assurance for long-term projects.

Insulation sheets are a practical way to improve building thermal performance when chosen and installed correctly. Understanding material properties, R-values, and installation practices helps ensure expected energy savings and comfort levels are realized while meeting code and durability needs.

Sources