Integrating Automation with Manual Workflows in Small-Scale Production

Small-scale production environments often combine hands-on assembly with automated aids. This article outlines practical approaches to blend automation and manual workflows so assemblers and managers can maintain flexibility, ensure consistent quality, and scale processes without losing craftsmanship or safety standards.

Small-scale production lines frequently rely on experienced assemblers performing hands-on tasks alongside semi-automated equipment. Integrating automation into these workflows requires deliberate planning: identify repeatable tasks, assess component complexity, and design processes that preserve manual skills while improving consistency. The balance between automation and manual labor affects throughput, quality, and worker safety, and it often begins with mapping existing operations in manufacturing and understanding which fabrication steps benefit most from tooling, fixtures, or simple robotics.

Manufacturing and production balance

Achieving the right balance between manufacturing efficiency and flexible production starts with process mapping. For small runs or mixed-model production, maintain modular workstations where assemblers can switch tasks without long retooling. Automation should target repetitive, ergonomically challenging, or precision-limited operations so production flow improves without removing human oversight. Planning for batch sizes, takt time, and the frequency of model changes helps determine whether conveyors, pick-and-place aids, or manual cells with light automation are appropriate for your facility.

Fabrication and components handling

Fabrication and component handling benefit from straightforward mechanical aids that reduce error and speed handling while keeping costs manageable. Use jigs, fixtures, and simple indexing tables to stabilize parts during assembly; these tooling solutions are especially useful when working with small components that require precise alignment. Establish clear receiving and storage procedures for components to minimize contamination and damage. In small-scale settings, flexible fixturing that adapts to multiple components preserves the ability to fabricate varied assemblies without major downtime.

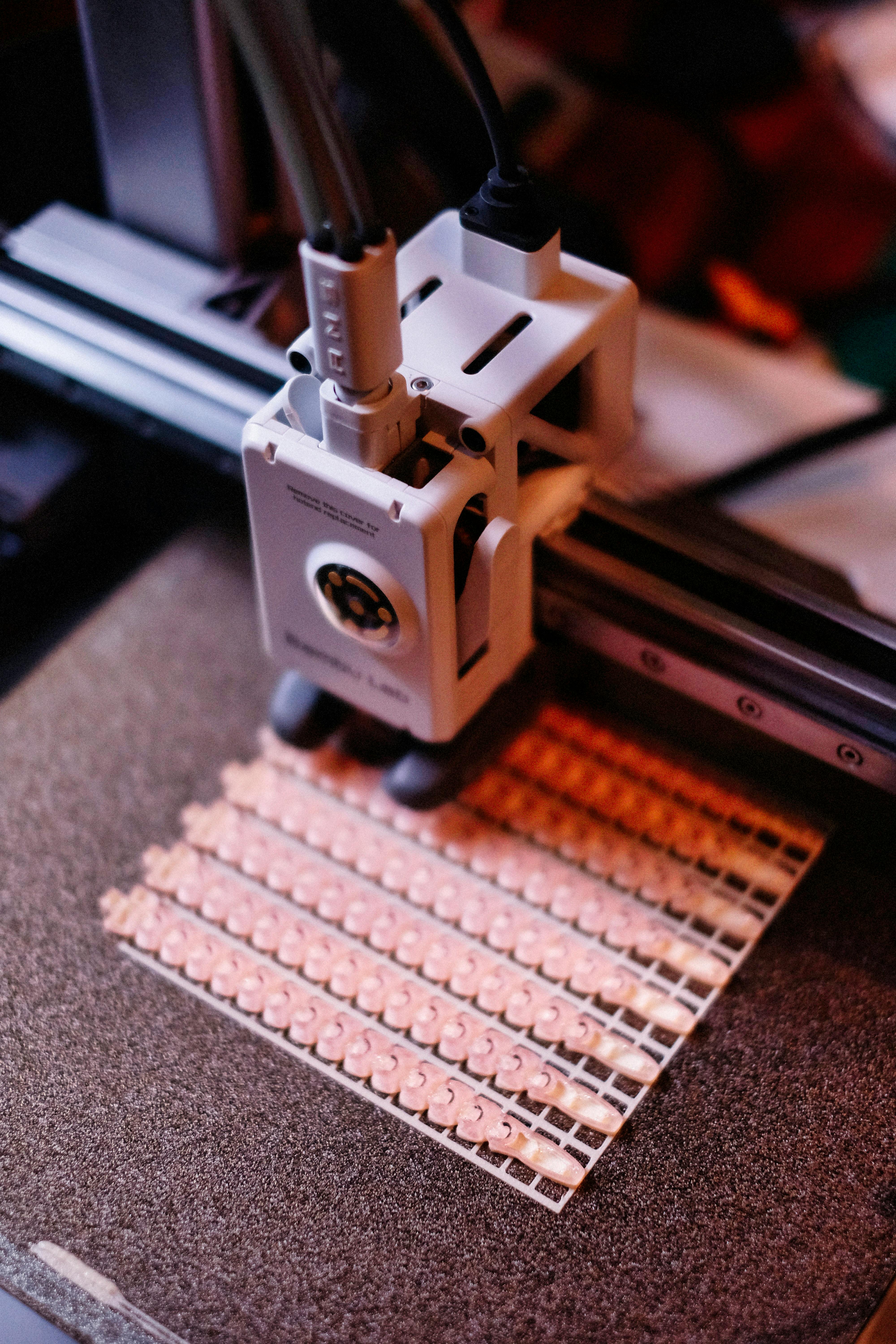

Electronics, soldering, and wiring

Electronics assembly in small production runs often combines manual soldering and wiring with selective automation like solder paste stencils or benchtop reflow ovens. For delicate components, manual soldering may be preferred, but automation can assist with repeatability through fixtures and pre-programmed heating profiles. Implement standardized processes for cable routing and harness assembly so wiring quality stays consistent. Clear assembly documentation and labeled components reduce error rates and support traceability when troubleshooting electronics assemblies.

Quality and inspection practices

Quality and inspection are central to blending manual and automated steps. Define inspection points where human judgment is required and where automated checks (such as vision systems or go/no-go gauges) can verify dimensions or component presence. For small-scale production, lightweight inspection tools—like portable microscopes and checklists—paired with digital records encourage compliance without heavy investment. Establish criteria for when an automated flag requires human review, ensuring inspection steps complement assembler responsibilities and maintain product quality.

Skills, training, and safety

Maintaining a skilled workforce is essential when automating selectively. Provide training that covers new tooling, safe interaction with robots or cobots, and troubleshooting of semi-automated equipment. Cross-training assemblers improves flexibility across production tasks and reduces disruption when workstations change. Safety protocols must be updated to reflect new interactions between humans and machines: establish lockout/tagout procedures, safe loading/unloading steps, and clear separation or collaborative modes for robotics. Emphasize ergonomics when designing manual tasks to lower injury risk and increase consistency.

Automation, robotics, and tooling integration

Introduce automation incrementally, starting with tooling and simple robotics that augment human capabilities. Collaborative robots (cobots) can assist with repetitive lifts or positioning, while programmable fixtures provide repeatability for soldering or fastening. Evaluate integration based on total cost of ownership, ease of programming, and maintenance requirements; choose systems that fit shop-floor skill levels. Keep tooling modular so physical changes are fast, enabling small-scale producers to adopt automation for repetitive sub-operations without committing to full-line automation.

In summary, integrating automation into manual workflows in small-scale production is a strategic exercise in trade-offs. Focus on augmenting human strengths—problem solving, adaptability, and fine motor control—while automating tasks that demand repeatability and precision. By investing in adaptable tooling, targeted training, and pragmatic safety measures, small manufacturers can improve consistency and capacity without sacrificing the flexibility that defines small-batch fabrication and electronics assembly. The outcome should be a resilient production system where assemblers and machines work together to meet quality and delivery goals.