Integrating temporary distribution sites with e-commerce fulfillment

Temporary distribution sites can bridge gaps in peak demand, events, or construction-driven disruptions by offering flexible, modular storage and fulfillment capacity. This article explains how temporary deployment, inventory staging, coldchain handling, and compliance with permits work together to support e-commerce operations while balancing sustainability and operational risk.

Temporary distribution sites offer a practical way to extend e-commerce fulfillment capacity without long-term construction. By combining modular storage units, short-term logistics planning, and clear protocols for inventory and coldchain management, retailers and logistics providers can respond to seasonal spikes, special events, or localized disruptions. Successful integration depends on planning for deployment and relocation, securing appropriate permits, and aligning temporary operations with existing fulfillment platforms and compliance standards while considering sustainability and local service availability.

How does modular temporary storage fit fulfillment?

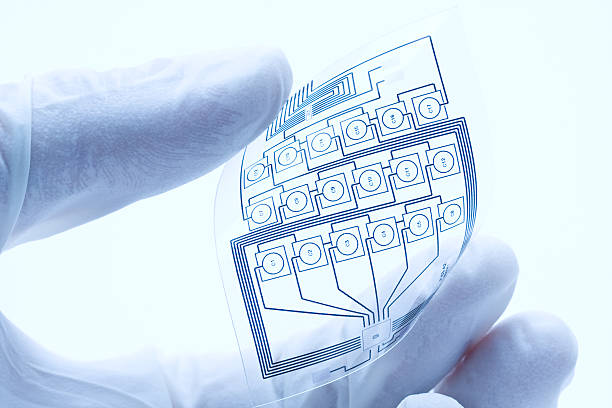

Modular units are designed for quick assembly and can be scaled to match order volume, providing a bridge between centralized warehouses and last-mile needs. For e-commerce fulfillment, modular temporary storage allows near-demand staging of inventory, faster picking for high-turn SKUs, and reduced transit times. Integration requires standardized racking, barcode or RFID systems compatible with warehouse management software, and predictable power and climate controls where needed. Proper layout planning reduces intra-site travel time and supports quicker order throughput while preserving inventory visibility across the network.

Managing logistics and inventory for temporary sites

Logistics for temporary sites focus on inbound replenishment, cross-docking, and outbound parcel consolidation. Clear inventory governance avoids split locations causing stock ambiguity: establish lot-level tracking, set minimum/maximum thresholds for automated replenishment, and designate buffer stock rules. Coordination with carriers for scheduled pickups and returns handling improves fulfillment reliability. Temporary sites also benefit from portable communication infrastructure so logistics teams can maintain visibility into order status, transit times, and exceptions, reducing latency and improving integration with e-commerce order management systems.

Deployment and relocation considerations for distribution

Deployment speed and ease of relocation are key advantages of temporary distribution. Site selection should consider ground preparation, vehicle access, utility hookups, and load-bearing capacity for stored goods and racking. Relocation plans must address packaging of modular units, transfer of inventory records, and continuity of outbound fulfillment during moves. Contractual clarity with providers on lead times, dismantling, and redeployment logistics reduces site downtime. A deployment checklist that includes insurance, temporary staffing, and contingency routing helps mitigate disruptions when moving operations between locations.

Coldchain, permits, and compliance requirements

Coldchain capabilities often dictate the feasibility of temporary distribution for temperature-sensitive goods. Use purpose-built refrigerated modules or portable coldrooms with monitoring and alarm systems integrated into fulfillment software to maintain product integrity. Permits vary by jurisdiction and can include occupancy, health, and fire safety approvals; early engagement with local authorities streamlines approvals. Compliance with labeling, traceability, and storage regulations must be enforced through documented procedures and regular audits to avoid regulatory risk and ensure product safety throughout temporary operations.

Sustainability, events, and construction impacts

Temporary distribution is commonly used for events or during construction-driven displacement of permanent facilities. Sustainable practices—such as reusable modular components, efficient lighting and heating, and optimized transport routing—reduce environmental impact. Short-term sites can support circular logistics by facilitating returns processing or localized redistribution, lowering long-haul movements. During events, temporary sites enable last-mile responsiveness while reducing the need for permanent expansion; during construction, they maintain fulfillment continuity. Evaluate lifecycle impacts of materials and include end-of-use recycling or reuse in planning.

Integration with e-commerce fulfillment platforms

Seamless integration requires data interoperability: inventory levels, order statuses, and shipping confirmations should synchronize in real time with e-commerce platforms and WMS/OMS systems. APIs or middleware can bridge temporary site operations with central systems, enabling automated order routing, pick-ticket generation, and carrier label printing. Define clear SLAs for order cutoffs and exceptions handling so customers receive consistent delivery estimates. Training temporary staff on platform workflows and using mobile scanning devices preserves data integrity and ensures temporary sites function as extensions of the core fulfillment network.

Conclusion

Integrating temporary distribution sites into e-commerce fulfillment provides operational flexibility to manage peaks, events, and facility interruptions while maintaining inventory control and customer expectations. Attention to modular design, logistics coordination, deployment planning, coldchain capabilities, permitting, and sustainability helps temporary sites perform reliably as part of a broader distribution strategy. With proper systems integration and governance, temporary distribution becomes a tactical tool for resilient, responsive e-commerce operations.