Laser Cleaning Technology: Revolutionizing Industrial Machinery Maintenance

Laser cleaning technology is transforming the landscape of industrial machinery maintenance, offering a powerful and efficient alternative to traditional cleaning methods. This innovative approach utilizes high-energy laser beams to remove contaminants, rust, and coatings from various surfaces without causing damage to the underlying material. As industries seek more effective and environmentally friendly cleaning solutions, laser cleaning has emerged as a game-changing tool in the maintenance of industrial machines.

The laser beam can be adjusted in terms of power, wavelength, and pulse duration to suit different cleaning requirements. This versatility makes laser cleaning suitable for a wide range of industrial applications, from removing rust on metal surfaces to cleaning delicate electronic components.

What are the advantages of laser cleaning for industrial machines?

Laser cleaning offers several significant advantages over conventional cleaning methods in industrial settings. Firstly, it is a non-contact process, which means there is no mechanical abrasion or chemical interaction with the surface being cleaned. This reduces the risk of damage to sensitive components and extends the lifespan of industrial machinery.

Additionally, laser cleaning is highly precise and can be automated, ensuring consistent results across large surface areas. It is also environmentally friendly, as it does not require the use of chemical solvents or produce hazardous waste. This makes it an attractive option for industries looking to reduce their environmental impact and comply with strict regulations.

Which industries benefit most from laser cleaning technology?

Laser cleaning technology has found applications across various industries, proving particularly beneficial in sectors that require high precision and cleanliness. The automotive industry uses laser cleaning for removing paint and rust from car bodies and engine components. In aerospace, it is employed for cleaning aircraft parts and preparing surfaces for coating.

The electronics industry benefits from laser cleaning in the maintenance of circuit boards and semiconductor manufacturing equipment. In the energy sector, laser cleaning is used for maintaining power generation equipment and cleaning solar panels. Heritage conservation also utilizes this technology for delicate cleaning of historical artifacts and buildings.

What types of laser cleaning machines are available?

Laser cleaning machines come in various configurations to suit different industrial needs. Handheld laser cleaning tools offer portability and flexibility for spot cleaning or working in hard-to-reach areas. These devices are particularly useful for maintenance technicians who need to perform cleaning tasks in various locations.

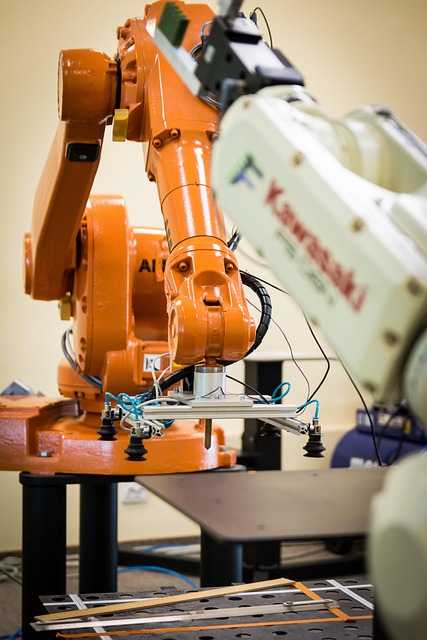

Larger, stationary laser cleaning systems are designed for high-volume industrial applications. These machines often feature automated systems and can be integrated into production lines for continuous cleaning operations. Some advanced models incorporate robotics and AI-driven controls for enhanced precision and efficiency.

How does laser cleaning compare to traditional cleaning methods?

| Method | Precision | Environmental Impact | Speed | Surface Damage Risk |

|---|---|---|---|---|

| Laser Cleaning | Very High | Low | Fast | Very Low |

| Sandblasting | Medium | Medium | Fast | Medium |

| Chemical Cleaning | Low | High | Slow | Medium to High |

| Manual Scrubbing | Low | Low | Very Slow | Medium |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Laser cleaning technology offers superior precision and minimal environmental impact compared to traditional cleaning methods. While the initial investment in laser cleaning equipment may be higher, the long-term benefits often outweigh the costs. Laser cleaning is faster than manual scrubbing and chemical cleaning, and it poses a lower risk of surface damage compared to abrasive methods like sandblasting.

What are the limitations of laser cleaning technology?

Despite its numerous advantages, laser cleaning technology does have some limitations. The initial cost of laser cleaning equipment can be substantial, which may be a barrier for smaller businesses. Additionally, laser cleaning may not be suitable for all types of materials or contaminants. Certain reflective surfaces or materials that are sensitive to heat may not be ideal candidates for laser cleaning.

Safety considerations are also important, as laser equipment requires proper training and protective measures to operate safely. The effectiveness of laser cleaning can also be influenced by the color and composition of the contaminants, as some materials may not absorb laser energy efficiently.

In conclusion, laser cleaning technology represents a significant advancement in industrial machine maintenance. Its precision, efficiency, and environmental benefits make it an increasingly popular choice across various industries. As the technology continues to evolve and become more accessible, it is likely to play an even more crucial role in the future of industrial cleaning and maintenance processes.