Laser Engraving: Applications, Equipment, and Customization

Laser engraving uses a focused light beam to mark or remove material from a surface. It is used across hobby, industrial, and creative contexts to add durable markings, cut parts, or create decorative effects. This article explains how lasers interact with common materials such as acrylic, describes beam behavior and safety considerations, explores crafting uses and customization techniques, and outlines key equipment choices for people seeking local services or planning to set up a workspace.

Acrylic materials and considerations

Acrylic is a popular substrate for laser engraving and cutting because it melts and vaporizes predictably under the right laser wavelengths. Cast acrylic typically yields a frosty, smooth engraved finish; extruded acrylic often burns and melts differently. Working with acrylic requires attention to feed rate, power, and focus to avoid excessive charring or cracking. Ventilation and fume extraction are important because acrylic processing can release irritating vapors. Masking with low-tack tape helps protect surfaces from soot and makes cleanup easier after engraving or cutting.

How a beam interacts with materials

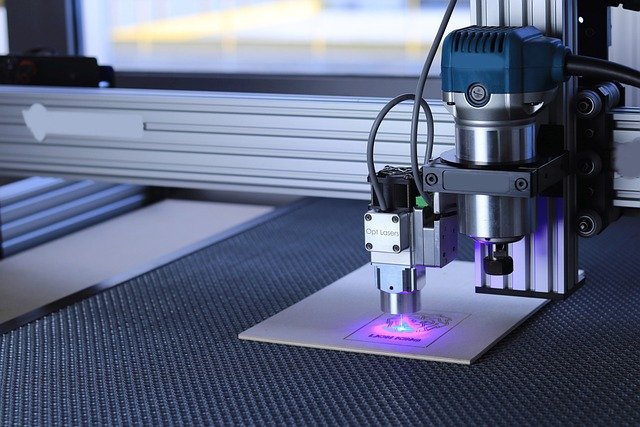

The laser beam’s wavelength, power, and focus determine how it marks or removes material. CO2 lasers (10.6 µm) are commonly used for organic materials and acrylic; fiber lasers (near-infrared) work well for metals and some plastics. Beam quality and focal spot size affect edge sharpness and engraving detail: a tighter focus yields finer lines but reduces the depth per pass. Pulse settings or air assist can reduce heat buildup, improving cut quality and lowering the chance of melt. Understanding these parameters helps operators achieve consistent results across different substrates.

Laser engraving for crafting projects

Crafters use laser engraving for signs, personalized gifts, model parts, inlay components, and small-batch products. Raster engraving produces shaded or photographic details by scanning the beam across the surface, while vector engraving follows paths for outlines and cuts. Combining engraving and cutting in a single job enables layered assemblies from materials like wood, leather, paper, and acrylic. For hobbyists, project planning includes material testing, nesting patterns to maximize sheets, and anticipating finishing steps such as sanding edges, painting, or applying adhesives for multi-layer assemblies.

Customization options and techniques

Customization ranges from simple text and logo engraving to complex multi-layer designs and variable data marking. Depth control allows subtle surface etching or deeper engraving for tactile effects. Techniques include masking to preserve glossy surfaces, applying fill inks for contrast, and using backlighting with engraved acrylic to enhance visibility. For variable personalization—serial numbers, names, or barcodes—software-driven workflows that import CSV or design variables streamline production. When seeking customization through local services, request material tests and sample proofs to confirm appearance before full runs.

Choosing the right equipment

Selecting equipment depends on intended materials, throughput, and workspace constraints. Small desktop CO2 systems are suitable for occasional acrylic work and light crafting; higher-wattage CO2 or fiber machines serve production needs and thicker cuts. Key specs to weigh include bed size, maximum power (watts), focal length options, ventilation requirements, and available accessories such as rotary attachments for cylindrical items. Consider software compatibility, maintenance needs, and available training or support. If you do not own equipment, local services or makerspaces often provide access to machines, training, and safety infrastructure.

Conclusion

Laser engraving offers precise marking, cutting, and decorative possibilities across materials and scales. Understanding how materials like acrylic respond, how the beam and settings affect results, and which tools and customization methods suit your projects helps improve outcomes and safety. Whether working through local services or investing in equipment, planning tests and documenting successful settings will make repeatable production and creative crafting more reliable.