Laser Engraving: Materials, Equipment, and Customization

Laser engraving uses a focused light beam to remove or alter a material’s surface to create precise marks, text, or images. The process is widely used for industrial marking, personalized gifts, and hobby crafting because it can work with many substrates and deliver high resolution detail. Understanding basic principles helps when choosing materials, equipment, and design approaches.

How does a laser beam interact with materials?

A laser beam delivers concentrated energy to a small area, causing localized melting, vaporization, or chemical change depending on the material and laser type. Interaction depends on wavelength, power, pulse duration, and material absorption. Metals, plastics, wood, and glass respond differently: some are ablated, others darken or fracture at the surface. Control of beam speed, focus, and power allows for varied effects such as deep engraving, surface marking, or cutting thin sheets. Proper settings prevent unwanted charring or cracking.

What should you know about engraving acrylic?

Acrylic is a common choice for laser crafting because it cuts cleanly and can produce polished edges. Cast acrylic typically engraves with a frosted, white appearance, while extruded acrylic may melt differently and yield varied finishes. Acrylic gives crisp text and detailed logos but can emit fumes when processed, so ventilation or extraction equipment is important. Thickness, color, and whether the piece is coated or masked also affect outcomes and post-processing needs such as cleaning or flame polishing.

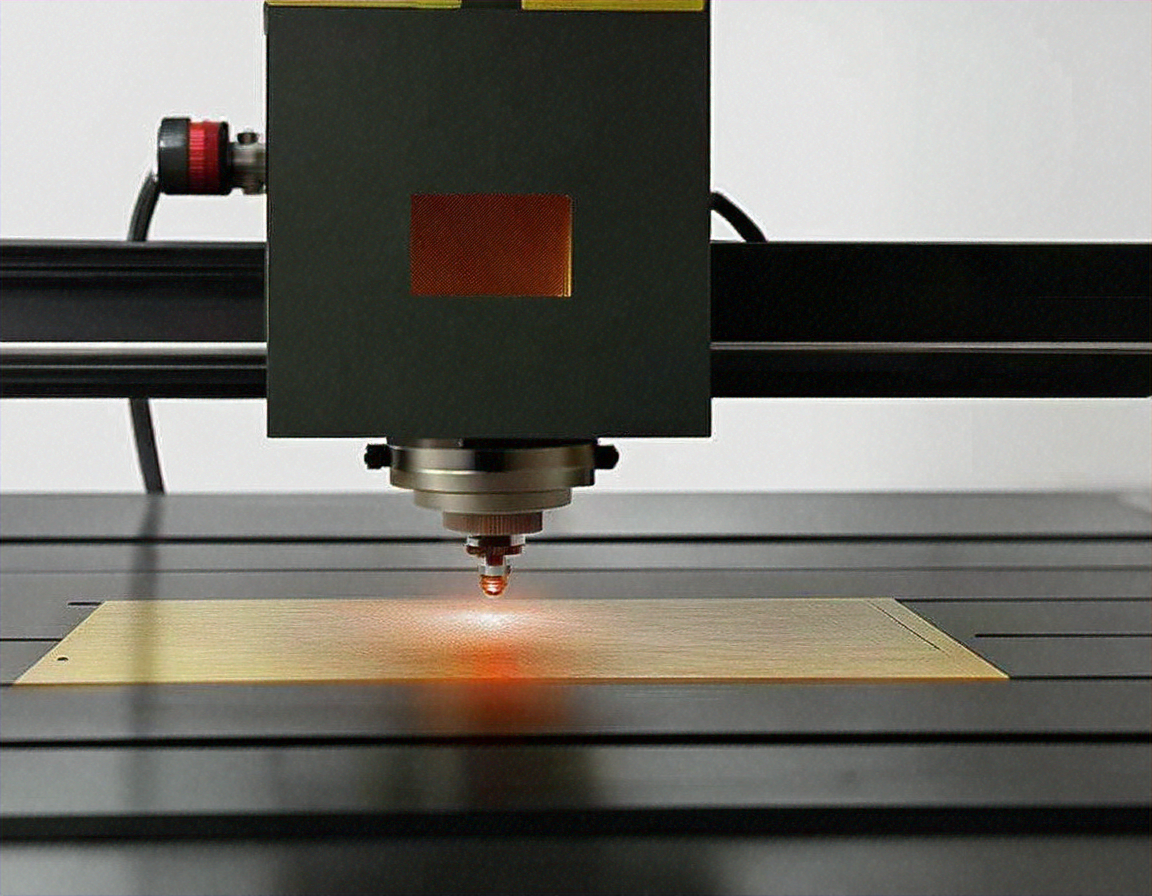

What equipment is used for laser engraving?

Typical equipment choices include CO2 lasers, fiber lasers, and diode systems. CO2 lasers (10.6 µm) are well-suited for organic materials, acrylic, and wood; fiber lasers are effective on metals and some plastics; diode lasers are compact and budget-friendly for light-duty projects. Essential accessories include proper ventilation or fume extraction, a stable workbed, software for vector and raster files, and safety interlocks. Regular maintenance—optics cleaning, alignment checks, and cooling system service—keeps results consistent.

How does customization work in laser engraving?

Customization begins with digital artwork prepared in vector or high-resolution raster formats. Designers set parameters—power, speed, frequency, and passes—to match material and desired depth or contrast. Templates and variable data tools let businesses personalize names, serial numbers, or barcodes at scale. For one-off items or small batches, customizable options include surface finishes, inlaying cut pieces, and combining engraving with other processes such as painting or anodizing for colored accents. Workflow organization and test cuts are critical to predictable customization outcomes.

How does laser engraving support crafting projects?

Laser engraving expands possibilities for hobbyists and makers by allowing precise cut shapes, intricate patterns, and detailed personalization on materials like wood, leather, acrylic, and paper. Crafters use it to produce signage, jewelry components, puzzles, and layered designs. Small-format desktop machines have lowered the barrier to entry, letting makers prototype quickly. Attention to material selection, glue and finish compatibility, and safe workspace ventilation helps ensure crafted pieces meet aesthetic and longevity expectations.

Conclusion

Laser engraving is a versatile technique that combines digital design control with physical material transformation. Familiarity with how the beam interacts with various substrates—especially common choices like acrylic—helps users predict visual outcomes and choose appropriate equipment. Selection between CO2, fiber, and diode systems depends on target materials and production needs, while workflow elements such as artwork preparation, parameter testing, and proper ventilation are essential for reliable results. For crafting and customization, laser engraving offers precise repeatability and options for adding personal or functional details. Whether for prototyping, small business production, or hobby projects, understanding equipment capabilities and material behaviors will lead to better choices and cleaner results.