Laser Engraving: Materials, Process, and Practical Uses

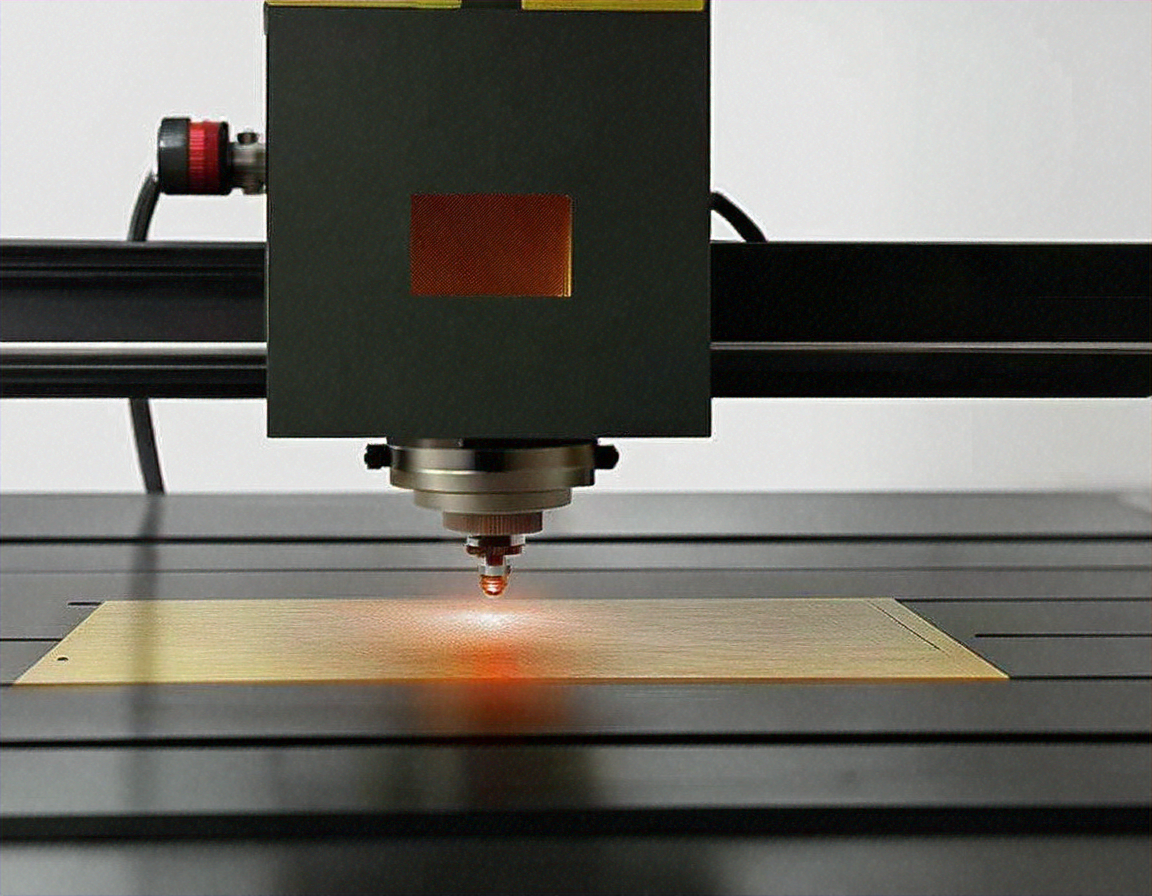

Laser engraving uses a focused light beam to remove or alter the surface of a material, creating marks, text, or images with precision. It is commonly used in manufacturing, crafting, and signage because it can render detailed designs repeatedly. Understanding how different materials respond, what equipment is needed, and how to prepare files helps both hobbyists and businesses decide whether to work in-house or use local services. Safety, ventilation, and correct machine setup are important considerations for consistent, clean results.

How does acrylic respond to laser engraving?

Acrylic, especially cast acrylic, is widely used for laser engraving and cutting because it produces clean edges and crisp engravings. Cast acrylic engraves to a frosted matte finish that contrasts with the clear or colored surface; extruded acrylic behaves differently and may melt more, so test cuts are recommended. When engraving acrylic, adjust power and speed to avoid chipping or melting, and ensure proper ventilation because fumes can be noxious. Masking tape or protective film can reduce surface scratches during handling and improve final visual quality.

What role does the laser beam play in results?

The laser beam’s wavelength, focus, power, and speed determine whether the process engraves, marks, or cuts. CO2 lasers are commonly used for organic materials and acrylic because their wavelength couples well with plastics and wood. Fiber lasers are better for metals and some plastics when marking rather than cutting. Beam focus and spot size affect detail: a smaller spot yields finer lines while higher power at slower speeds cuts deeper. Consistent beam alignment and routine maintenance keep results predictable across jobs.

How is laser engraving used in crafting projects?

Laser crafting opens opportunities for intricate pieces that are difficult to produce by hand: jewelry, inlays, layered signs, and personalized gifts. Designers typically prepare vector files for cutting and raster files for photographic engraving; software can convert images to halftones for shading effects. For makers, small-format desktop lasers make prototyping accessible while modular jigs and rotary attachments expand capability to cylinders and uneven surfaces. Practice on scrap materials to refine settings and to learn how different fillings, paints, or adhesives interact with engraved surfaces.

What customization options should you consider?

Customization starts with file preparation: vectors in SVG, DXF, or AI formats for cutting; high-resolution PNG or BMP for raster engraving. Material choice, color contrast, and post-processing (painting engraved areas, backlighting acrylic, or adding inserts) influence the final look. Consider durable marking methods when items will undergo wear or exposure. For customer-facing customization—names, serial numbers, or logos—implement a workflow that standardizes text sizes, fonts, and spacing to maintain consistent branding across runs. When outsourcing, communicate desired tolerances and finish expectations to local services.

How to choose and maintain laser equipment effectively?

Selecting equipment depends on materials, bed size, and throughput. Hobbyists often start with CO2 desktop units for acrylic and wood; businesses may choose larger CO2 or industrial fiber systems depending on volume and metal work. Key features to review include ventilation ports, exhaust systems, focal adjustment, and safety interlocks. Regular maintenance—cleaning mirrors and lenses, checking belt tension, and verifying beam alignment—prolongs life and maintains cut quality. If acquiring equipment is impractical, many communities offer access through makerspaces or local services where trained operators can run jobs on professional machines.

Conclusion

Laser engraving combines precision light-based machining with a wide range of materials and creative possibilities. Knowing how acrylic responds, how beam characteristics influence outcomes, and how to prepare files for crafting and customization helps users achieve predictable results. Choose equipment and workflows that match project scale, and prioritize safety measures such as adequate ventilation and routine maintenance. Whether working independently or using local services, testing and documentation lead to consistent, high-quality engraving outcomes.