Laser Engraving: Methods, Materials, and Practical Uses

Laser engraving uses a focused laser beam to remove or alter the surface of materials, creating marks, patterns, or cuts with high precision. It’s used across industries and hobbies for customization and fabrication—everything from signage and industrial nameplates to detailed crafting projects. The process depends on factors like the type of material, the laser beam characteristics, design file quality, and the equipment used. Understanding how different materials react, how to prepare artwork, and what equipment fits a project helps makers, designers, and small businesses achieve consistent results while keeping safety and workflow efficiency in mind.

How does acrylic respond to laser engraving?

Acrylic is among the most commonly engraved plastics because it produces clean edges and predictable results. When engraved with a CO2 laser, cast acrylic typically yields a frosted, white mark as the surface vaporizes, while engraved edges remain smooth and often require minimal finishing. Plexiglas (extruded acrylic) may melt differently and can produce more glossy cuts. Masking the surface before engraving helps reduce soot and keeps edges clear. Beware of fumes: acrylic generates volatile organic compounds when cut, so proper ventilation and filtration equipment are essential for safe operation.

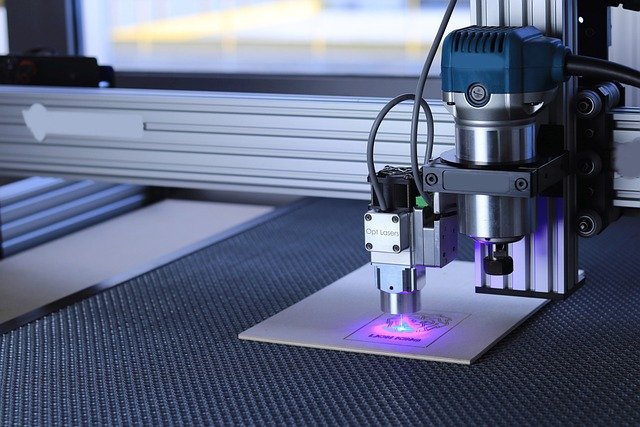

What role does the laser beam play in outcomes?

The beam’s wavelength, power, focus, and pulse characteristics determine how a material is cut or marked. CO2 lasers emit longer wavelengths suited to organic materials and many plastics; fiber lasers are better for metals and some polymers. Beam focus and focal length affect resolution and kerf (material removed), while power and speed settings control depth and heat buildup. Pulse frequency can influence the texture of an engraved surface. Proper alignment and regular beam calibration ensure consistent engraving across batches, and software control of raster and vector modes lets operators choose between marking surfaces and cutting through materials.

How is laser engraving used in crafting projects?

Crafters use laser engraving for fine detailing, layered assemblies, and personalized gifts. Popular crafting applications include engraved ornaments, jewelry components, custom puzzles, stencils, and leather or fabric accents. The technology enables intricate patterning that would be difficult or time-consuming by hand, and it integrates well with other techniques such as inlay, painting, or sublimation. Planning for material thickness, holding fixtures, and post-processing (like edge polishing for acrylic) helps produce professional-looking pieces suitable for sale or exhibition.

What customization options do designers control?

Customization begins with the digital artwork: vector files for cutting and deep engraving, and high-resolution raster images for surface shading and photos. Designers can adjust engraving depth, halftone density, line weight, and font choice to influence legibility and aesthetic. Kerf compensation, nesting parts to reduce waste, and using engraving passes rather than a single deep cut help manage precision. Surface finishing—such as color filling engraved grooves or applying solvent polishing to acrylic—adds another dimension to customization. Communicating file requirements and material tolerances ensures predictable results between designer and operator.

What equipment and safety considerations matter?

Equipment ranges from compact diode or CO2 desktop units for hobbyists to industrial fiber lasers for metalwork. Key accessories include ventilation and fume extraction systems, honeycomb or sacrificial beds, rotary attachments for cylindrical items, and water cooling for higher-power lasers. Regular maintenance—lens cleaning, belt tension checks, and software updates—preserves beam quality. Safety involves enclosure interlocks, appropriate eyewear rated for the laser wavelength, and monitoring for material-specific hazards (for example, PVC produces corrosive gases and should not be laser cut). If you need production help, check local services or providers in your area that offer laser cutting and engraving to inspect samples or run batches.

Conclusion

Laser engraving blends precise optics and material science to deliver durable marks, cuts, and fine detail across a wide range of substrates. Knowing how materials like acrylic react, how beam parameters affect results, the creative possibilities for crafting, and the degree of customization available helps users choose the right approach for their projects. Appropriate equipment selection, routine maintenance, and attention to ventilation and safety complete a reliable workflow that supports both one-off artisan pieces and repeatable production runs.