Manufactured Homes: Design, Residential Use, and Architectural Considerations

Manufactured homes are factory-built dwellings that have evolved significantly in materials, design, and performance. Once associated with single-section trailers, modern manufactured housing now includes multi-section units, higher quality finishes, and features that overlap with site-built homes. Understanding their construction standards, design possibilities, and how they fit into residential contexts helps homeowners, planners, and designers evaluate whether a manufactured home suits their needs.

What is a manufactured home?

A manufactured home is a dwelling constructed in a factory and transported to its site, built according to the federal HUD Code for manufactured housing. Unlike modular homes, which are built to local or state building codes and assembled on site, manufactured homes are produced on a continuous assembly line and certified to HUD standards that cover structural design, fire safety, energy efficiency, and transportability. Factory production allows for consistent quality control, predictable timelines, and the ability to integrate many modern systems before delivery.

How does modern design fit manufactured homes?

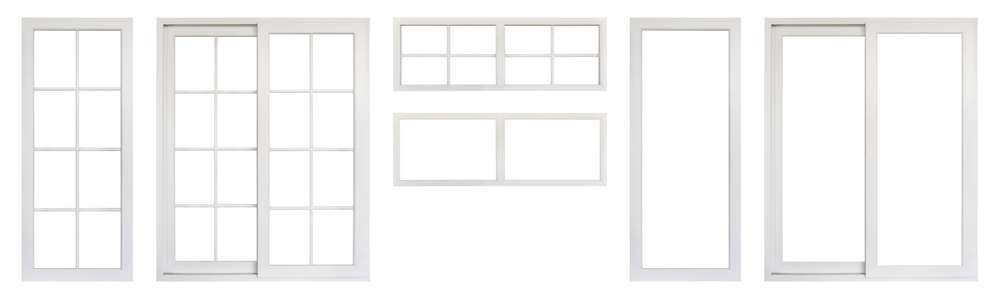

Modern design principles—clean lines, open plans, and efficient use of space—translate well to manufactured homes. Manufacturers increasingly offer customizable floor plans with features such as vaulted ceilings, integrated storage, and larger windows that enhance natural light. Contemporary exterior finishes, varied rooflines, and modular porch or deck attachments can give a manufactured home a modern curb appeal. Advances in insulation, HVAC, and window performance also enable modern manufactured homes to meet higher thermal-efficiency expectations common in site-built contemporary design.

Where do manufactured homes sit in residential planning?

In residential developments and single-family placements, manufactured homes can function as primary residences, secondary dwellings, or part of planned communities. Zoning and local ordinances determine where manufactured homes are permitted; some areas allow them in residential zones or dedicated manufactured-home communities. Foundations range from temporary stand systems to permanent concrete footing foundations that make a unit indistinguishable from on-site construction in appearance and permanence. Because placement and community rules vary, consulting local services or planning offices in your area is a practical step before purchase or installation.

Interior design strategies for manufactured homes

Interior design in manufactured homes focuses on maximizing perceived space and function. Lightweight, multi-functional furniture, built-in shelving, and zoned lighting enhance usability in smaller footprints. Color schemes that use light neutrals and reflective surfaces increase perceived volume, while vertical storage solutions free floor area. Kitchen and bath layouts in modern manufactured units often mirror site-built designs: full-height cabinetry, integrated appliances, and durable surfaces. Incorporating energy-efficient fixtures and smart home controls can improve comfort and reduce operating costs without major structural changes.

Architecture and site considerations for manufactured units

Architectural considerations include integrating the home with its topography, access, and utilities. Site preparation covers foundation type, drainage, utility hookups, and local permitting. Roof pitch, overhangs, and exterior cladding should be chosen to suit local climate and neighborhood context. When placed on a permanent foundation, a manufactured home can meet many architectural expectations of longevity and resale appeal. Transport limitations influence maximum width and section counts, so larger projects may require on-site assembly of multiple modules. Coordination with contractors familiar with manufactured-home set-up helps ensure compliance with both HUD requirements and local building codes.

Manufactured homes can also be adapted for sustainability and resilience. Options include high-performance insulation, heat-recovery ventilation, photovoltaic-ready roofs, and resilient exterior materials. Working with designers and builders who understand both HUD constraints and local architectural norms will yield better integration with the surrounding residential fabric.

Conclusion

Manufactured homes have moved beyond simple, uniform models to become flexible housing options with modern design capabilities, practical interior design strategies, and meaningful architectural choices. Their factory construction offers consistent quality and shorter timelines, while site planning and local regulations shape how they fit into residential areas. Careful attention to design details, foundation choices, and local permitting helps ensure a manufactured home meets both personal needs and neighborhood standards.