Manufacturing Jobs and Careers in the Netherlands

Manufacturing offers a wide range of roles from hands-on production to technical maintenance, design, and management. This article explains typical manufacturing jobs, how careers progress, and what training and education pathways are commonly used — with a focus on opportunities and considerations in the Netherlands. It provides general guidance rather than active job listings or specific openings.

What does manufacturing work involve?

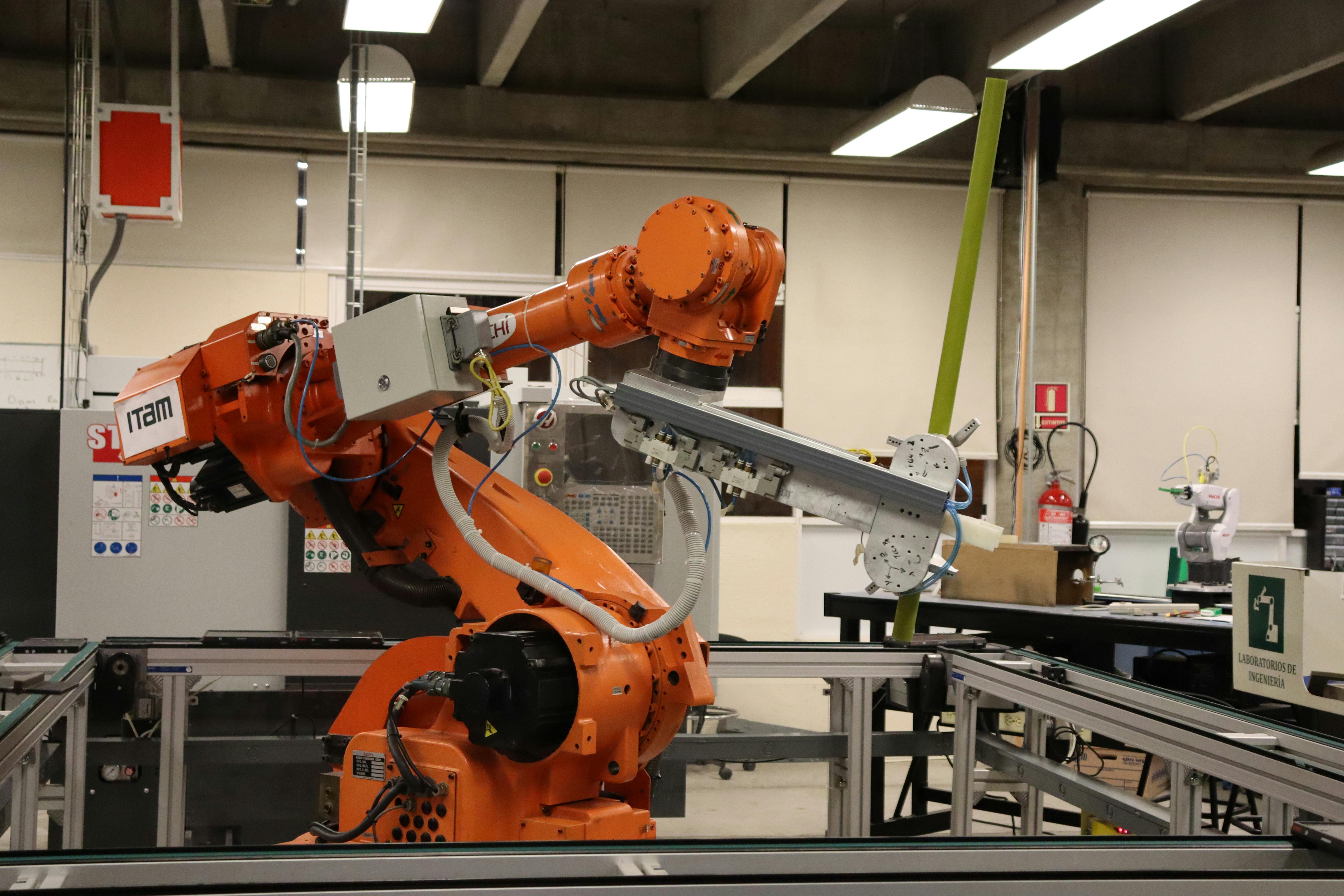

Manufacturing covers activities that transform raw materials into finished goods. Roles can include machine operation, assembly, quality inspection, maintenance, and production supervision. Modern manufacturing increasingly integrates automation, robotics, and industrial software, so workers often combine mechanical skills with basic IT literacy. Work environments vary from cleanrooms and production halls to research and prototyping labs. Safety, process adherence, and teamwork are core aspects across most positions.

Career paths and job levels in manufacturing

A manufacturing career often begins in entry-level production or technician roles and can progress to specialist, supervisory, or engineering positions. Common progression steps include operator → technician → team leader → process engineer → production manager. Parallel technical tracks may lead to roles in quality assurance, maintenance engineering, or automation programming. Soft skills such as problem solving, documentation, and communication become increasingly important at higher levels alongside technical expertise.

Manufacturing jobs in the Netherlands: landscape and guidance

The Netherlands hosts a diverse manufacturing sector that includes precision engineering, food processing, chemicals, and equipment manufacturing. Multinational companies and small-to-medium enterprises both hire locally and internationally. Note: this article offers general background and guidance, not live job listings. For current vacancies, consult company career pages, recognised job boards, trade unions, or local services that support employment. Verify requirements and application details with official employers and recruiters.

Training and apprenticeships for manufacturing roles

Practical training and apprenticeships remain central to many manufacturing roles. On-the-job apprenticeships combine workplace experience with classroom learning, helping trainees develop practical competencies. Short technical courses and vendor-specific certifications (e.g., for PLCs or welding standards) are commonly used to upskill. Employers also value training in safety systems (lockout/tagout, PPE use) and continuous improvement methods like Lean and Six Sigma at an introductory level.

Education and certification options

Formal education ranges from vocational diplomas to university degrees depending on role. Vocational tracks focus on applied skills for operators and technicians, while bachelor’s degrees (engineering, industrial technology) prepare candidates for design and management roles. Professional certificates in maintenance, automation, welding, or quality management can enhance employability. Continuous learning through evening courses or company-sponsored training helps workers adapt to evolving technologies and regulatory standards.

How to search, apply, and advance in manufacturing

When seeking manufacturing roles, combine online searches with local services such as employment centers, vocational schools, and industry associations. Tailor applications to highlight hands-on experience, certifications, and safety training; include measurable outcomes like process improvements or uptime metrics when possible. Networking with local suppliers and attending industry open days can reveal hidden opportunities. Be aware that recruitment cycles and language requirements vary by employer — check job postings for required permits, language levels, and whether relocation support is available.

This article is intended as informational career guidance and does not list or guarantee employment opportunities. To find current, actionable job vacancies, consult established job boards, company career pages, licensed recruiters, or official employment services. Verify all job details, application procedures, and contractual terms with prospective employers before committing.

Manufacturing careers combine practical skills, ongoing education, and adaptability to technology. Whether starting as an operator or moving toward engineering and management, clear training pathways and targeted certifications can help build a stable career in manufacturing in the Netherlands or in your area.