Manufacturing Jobs: Career Paths and Training in the Netherlands

The manufacturing sector offers a wide range of roles from machine operator to process engineer, and it increasingly combines hands-on skill with digital know-how. This article outlines typical manufacturing jobs, routes for building a career, common training options and the role of formal education, with specific context for working in the Netherlands. This is an informational overview only; it does not include active job listings or guarantees of employment and should not be treated as a source of current openings.

What do manufacturing jobs involve?

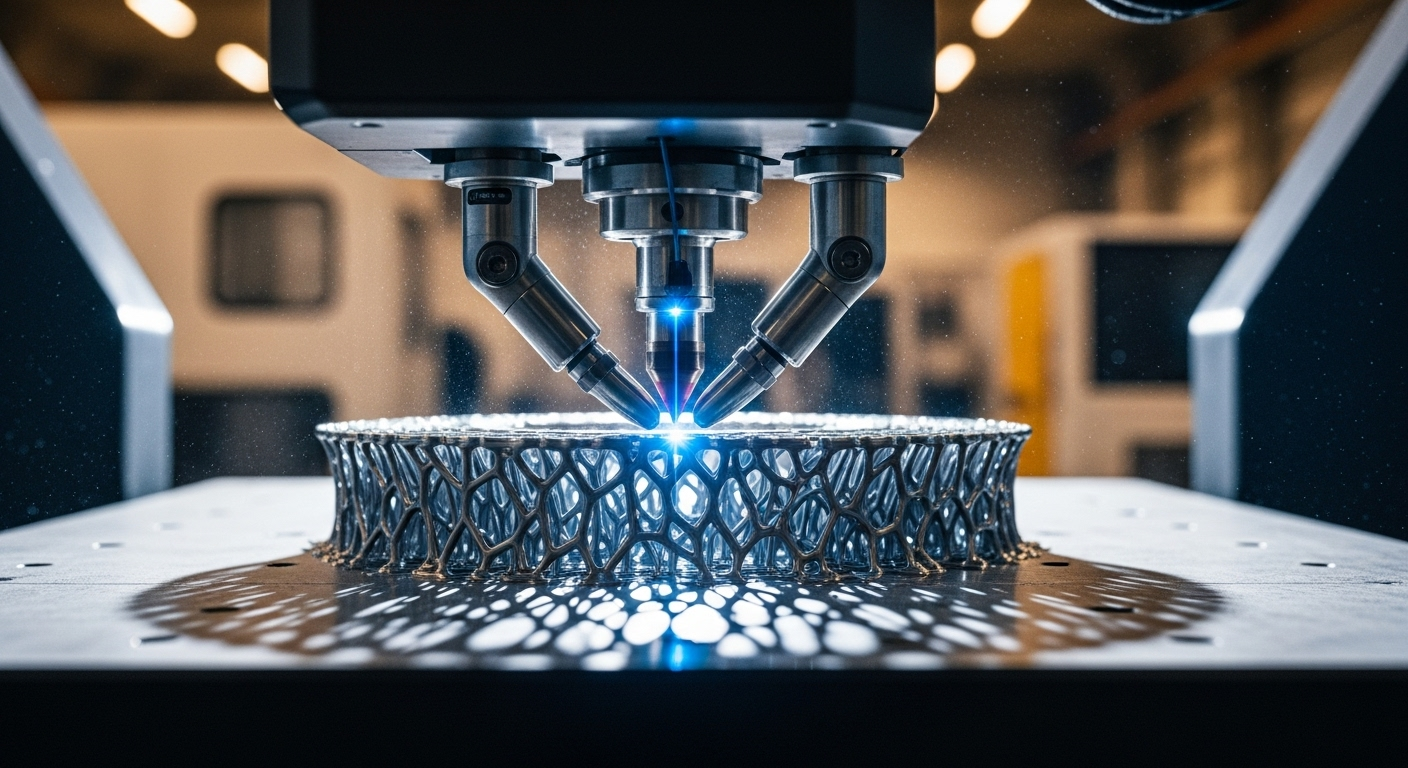

Manufacturing jobs cover production, assembly, maintenance, quality control and logistics. Entry-level roles often include machine operators, production assistants and assembly technicians who follow standard procedures and use basic tools or machines. Mid-level roles include maintenance technicians, process technicians and quality inspectors responsible for troubleshooting, preventative maintenance and ensuring products meet specifications. Senior roles commonly involve production management, process engineering, R&D and supply-chain coordination. Modern manufacturing increasingly involves automation, sensors and data collection, so many positions require both mechanical aptitude and familiarity with computerized control systems.

How can you build a manufacturing career?

A manufacturing career can progress through a mix of on-the-job experience, certifications and structured promotion. Start by gaining practical experience in entry-level roles to learn production rhythm, safety practices and basic machine operation. Seek internal training, cross-training across departments, and targeted qualifications (for example in CNC operation, PLC basics or quality systems). Soft skills—problem solving, communication and teamwork—are important for supervisory or specialist roles. Networking within industry associations or trade partner programs can surface development opportunities. Note that this article does not provide active job vacancies or placement services; it is intended to describe career pathways, not to list openings.

What training is available for manufacturing roles?

Training ranges from short courses to multi-year apprenticeship programs. Common offerings include vocational workshops, manufacturer-led certification (e.g., machine vendor training), health and safety certificates, and courses in lean manufacturing or quality management. Apprenticeships and traineeships pair workplace learning with classroom instruction and are especially common in technically focused industries. Many employers also provide in-house training for specific equipment and software. For workers transitioning into manufacturing from other sectors, modular courses in technical fundamentals (electrical basics, hydraulics, reading technical drawings) can speed up employability.

How does education affect manufacturing jobs?

Education helps determine the type of roles you can access and how quickly you advance. Vocational qualifications and apprenticeships often lead directly into technician and operator roles. Higher professional education (applied sciences or engineering degrees) opens pathways into process engineering, production planning and management. Continuous professional development—short courses, certifications and vendor-specific training—supports moves into automation, maintenance and quality assurance. Employers typically value demonstrable technical skills, safety awareness and hands-on experience as much as formal degrees, so combining education with practical experience is effective.

What is working in the Netherlands like for manufacturing?

The Netherlands hosts a diversified manufacturing base including food processing, high-tech components, metalworking and chemical-related production. Work environments often combine automated production lines with skilled technical maintenance. Dutch vocational pathways commonly include school-based and work-based programs that align with employer needs. Language expectations vary: some international or high-tech firms operate largely in English, while many local workplaces use Dutch for safety briefings and team coordination. Employment conditions, workplace safety regulations and apprenticeship arrangements reflect national standards; the exact terms and requirements depend on the employer and region. This article does not provide specific employer listings or contact details.

Skills, trends and practical considerations

Important skills include mechanical troubleshooting, basic electrical understanding, measurement and inspection techniques, and growing competencies in digital tools such as PLCs, human-machine interfaces and basic data capture. Industry trends affecting jobs include greater automation, predictive maintenance using sensor data, and modular production practices. For job seekers, practical considerations include verifying required certifications, understanding shift patterns, and ensuring training records are up to date. If relocating to the Netherlands, review local credential recognition and language requirements with reputable authorities and employer resources rather than relying on this overview for placement.

In summary, manufacturing jobs present varied entry points and clear development pathways that combine practical experience, targeted training and formal education. The Netherlands offers a mix of traditional and high-tech manufacturing opportunities, with vocational options and employer-led training playing a strong role in career development. This article is descriptive and does not include active job listings or guarantees of employment; consult official employer websites, national education providers or recognised job platforms for current openings and application procedures.