Manufacturing Jobs in Spain: Career Paths, Training, Education

Manufacturing in Spain covers a wide range of industries—from automotive and food processing to pharmaceuticals and electronics—and offers roles for different skill levels. This article explains common types of manufacturing jobs, how a career can begin and progress, what training and education support those paths, and regional considerations in Spain, without implying there are specific job openings.

What roles exist in manufacturing?

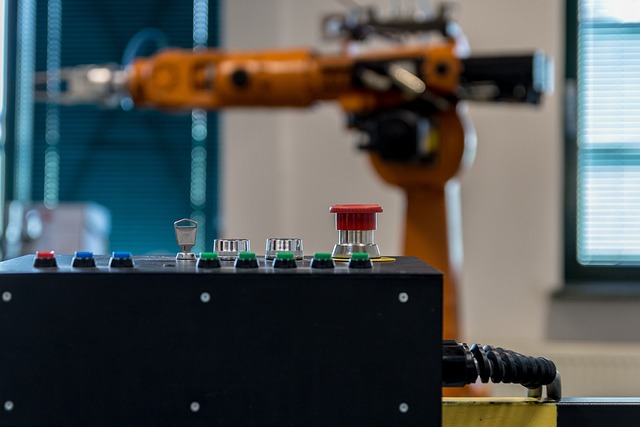

Manufacturing roles range from entry-level production operators to specialised technicians, maintenance staff, quality inspectors, process engineers and product designers. Operators often handle assembly, packaging or machine tending, while technicians work on equipment setup, troubleshooting and preventive maintenance. Engineering roles focus on process optimisation, automation and product development. Logistics, procurement and quality assurance are also integral to factory operations. Many roles require a mix of hands-on skills, familiarity with digital control systems and an ability to follow safety and quality standards.

How can a career start in manufacturing?

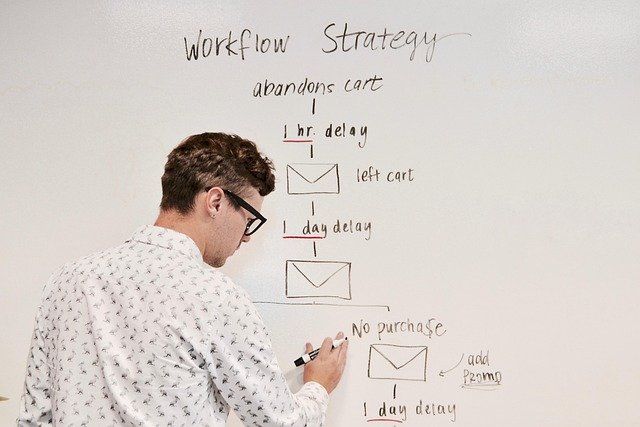

Careers in manufacturing commonly begin through apprenticeship programs, vocational training (Formación Profesional), or entry-level positions on the shop floor. Employers often support on-the-job training to build practical skills before employees move into technical or supervisory roles. Career progression can follow multiple paths—technical specialisation (e.g., CNC, robotics), horizontal moves into logistics or quality, or higher education routes such as engineering degrees. Language skills and basic digital literacy help with advancement, especially in facilities using automated systems and industry-standard software.

What training is needed for manufacturing jobs in Spain?

Training needs vary by role. Basic production work typically requires safety training, machinery-specific instruction and familiarity with standard operating procedures. Technical jobs often call for formal certificates from vocational schools (FP) in areas like industrial maintenance, electronics or mechatronics. Advanced roles may require programming skills for PLCs, robotics, CAD tools and knowledge of manufacturing standards. Training can be obtained through public vocational centres, private academies, company-sponsored programs and online courses. Local services and training centres can help match course offerings to employer needs.

How does education support advancement in manufacturing?

Education supports both entry and upward mobility. Short-term certificates and FP programs provide practical skills for immediate work, while university degrees in engineering, industrial design or materials science open pathways to R&D, process engineering and management. Continuous education—such as micro-credentials, part-time master’s programs or specialised workshops—helps workers adapt to Industry 4.0 trends like automation, data analytics and additive manufacturing. Recognition of qualifications within the EU facilitates mobility for professionals moving between Spain and other member states.

Working conditions and regional differences in Spain

Working conditions in manufacturing vary by company, sector and region. Industrial hubs such as Catalonia, the Basque Country, Valencia, Madrid and Navarre host concentrations of automotive, machinery and food processing plants, which can influence the types of roles and training available locally. Shift work, temporary contracts and collective bargaining agreements are common considerations. Health and safety regulations are regulated nationally and implemented at company level; many employers provide protective equipment and training. Salary levels and career progression opportunities differ regionally and by industry sector.

Conclusion

Manufacturing jobs in Spain encompass a broad spectrum of roles and require diverse combinations of practical skills, formal training and continuing education. Prospective workers and those seeking career progression should assess local training options, industry-specific skill requirements and regional labour market characteristics. This article is informational and does not list or imply active job openings; it focuses on the types of roles, common pathways and educational supports relevant to manufacturing careers.