Manufacturing jobs in the Netherlands: roles, skills, and pathways

Manufacturing remains a major area of employment worldwide, with positions ranging from production operatives to engineers and supervisors. This article outlines common manufacturing jobs, the skills employers often seek, and typical pathways into factory and industry roles in the Netherlands and other countries. It does not list specific vacancies or guarantee employment.

Manufacturing roles and responsibilities

Manufacturing roles cover a broad spectrum of tasks. Entry-level positions often include assembly, machine operation, packing and basic quality checks. Skilled roles can include maintenance technicians, CNC machinists, electricians, and process operators. Supervisory and engineering positions involve process optimisation, product design support, and continuous improvement activities. Responsibilities vary by employer and product type but generally center on producing consistent, safe, and high-quality output.

How to build a career in manufacturing

A manufacturing career typically develops through a combination of on-the-job experience, formal training, and credentialing. Many workers start in production roles to gain practical experience, then move into specialised functions through targeted courses or internal training. Professional development options include technical certificates, apprenticeships, and sector-specific short courses. Soft skills such as communication, problem solving, and adherence to safety standards are commonly valued alongside technical competence.

Working in a factory in the Netherlands

Factory work in the Netherlands reflects both traditional manufacturing and advanced industry segments such as high-tech, food processing, and logistics. Working conditions are influenced by national labour regulations, collective agreements, and company policies; these shape working hours, safety protocols, and worker benefits. Multilingual workplaces are common in international firms. For those considering employment, it is useful to review statutory labour protections, required permits for non-EU nationals, and local industry norms to understand expectations in Dutch factory environments.

Industry skills and qualifications

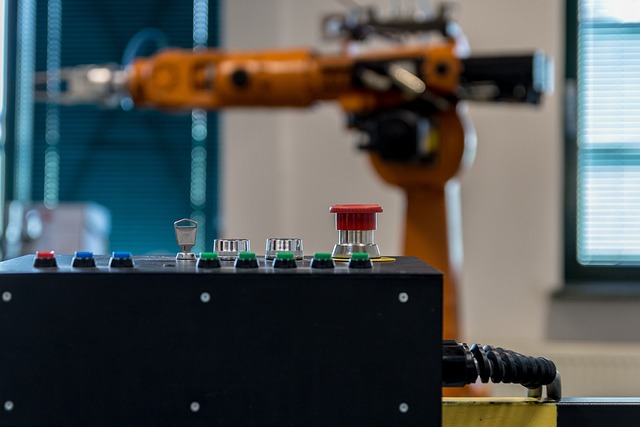

The wider industry often requires a mix of hard and soft skills. Technical skills include machine programming, electrical systems knowledge, welding, and quality assurance techniques (for example, familiarity with ISO standards or Six Sigma basics). Digital literacy is increasingly important as factories adopt automation and data-driven monitoring. Qualifications can range from vocational diplomas to bachelor-level engineering degrees depending on role complexity. Employers increasingly value documented training, safety certifications, and proven experience operating relevant equipment.

Training, apprenticeships, and local services

Training routes commonly referenced for manufacturing careers include vocational programs, apprenticeships, and short technical courses offered by educational institutions and training providers. These programs focus on hands-on skills, safety, and industry-relevant credentials; however, participation does not guarantee job placement. When considering training or local services, review course content, accreditation, and any employer links the provider has. Verify whether a program supplies recognized qualifications and ask about the practical experience component to ensure alignment with desired factory or industry roles.

Career mobility and workplace trends

Manufacturing continues to evolve with automation, sustainability measures, and supply-chain shifts. These trends can affect the types of jobs available and the skills in demand. Workers with a mix of mechanical aptitude, digital capabilities, and adaptability are better positioned for internal mobility or role changes within factories. Lifelong learning and periodic skills updates are common aspects of sustaining a long-term career in the sector. Note that this overview is informational and does not indicate the availability of specific job openings.

Conclusion

Manufacturing jobs span a wide range of responsibilities and require varied skill sets, from practical trade abilities to engineering and digital competencies. In the Netherlands and elsewhere, factory roles reflect local regulations and industry specialisations, and career progression commonly combines experiential learning with formal training. This article provides general information about roles and pathways without offering specific job listings or employment guarantees.