Metamaterial Applications in Automotive Sound Engineering

Metamaterials are revolutionizing automotive sound engineering by offering unprecedented control over acoustic properties in vehicles. These artificially engineered materials manipulate sound waves in ways impossible with conventional materials, enabling automotive engineers to create quieter cabins, enhance audio systems, and improve overall driving experiences. From active noise cancellation to advanced speaker technologies, metamaterial integration represents a significant leap forward in automotive acoustic design and passenger comfort.

Piezoelectric Integration in Sound Control Systems

Piezoelectric materials play a crucial role in modern automotive sound engineering when combined with metamaterial structures. These materials convert mechanical stress into electrical energy and vice versa, making them ideal for active noise control systems. In vehicles, piezoelectric actuators embedded within metamaterial panels can dynamically adjust their acoustic properties in real-time, responding to engine noise, road conditions, and passenger preferences. This technology enables precise sound wave manipulation, creating zones of silence or enhanced audio clarity throughout the vehicle cabin.

Graphene Enhancement in Acoustic Materials

Graphene integration into metamaterial designs has opened new possibilities for lightweight yet highly effective sound dampening solutions. The exceptional strength-to-weight ratio of graphene allows engineers to create ultra-thin acoustic barriers that outperform traditional materials. These graphene-enhanced metamaterials can be strategically placed in door panels, floor sections, and roof linings to significantly reduce external noise penetration while maintaining structural integrity and fuel efficiency through weight reduction.

Biomimetic Design Principles in Vehicle Acoustics

Biomimetic approaches in metamaterial development draw inspiration from nature’s sound management solutions. Engineers study how owls achieve silent flight or how certain marine animals navigate using echolocation to design automotive acoustic systems. These biomimetic metamaterials feature micro-structures that mimic natural sound-absorbing surfaces, creating materials that can selectively filter frequencies while allowing desired sounds to pass through. This selective permeability proves invaluable for maintaining communication clarity while reducing unwanted noise.

Wireless Power Transfer and Acoustic Optimization

Wireless power systems in vehicles require careful acoustic consideration, as electromagnetic fields can generate unwanted noise. Metamaterial shields designed specifically for wireless charging systems help minimize electromagnetic interference while maintaining power transfer efficiency. These specialized materials create acoustic barriers that prevent charging-related sounds from entering the passenger compartment, ensuring that convenience features don’t compromise the quiet cabin environment that modern drivers expect.

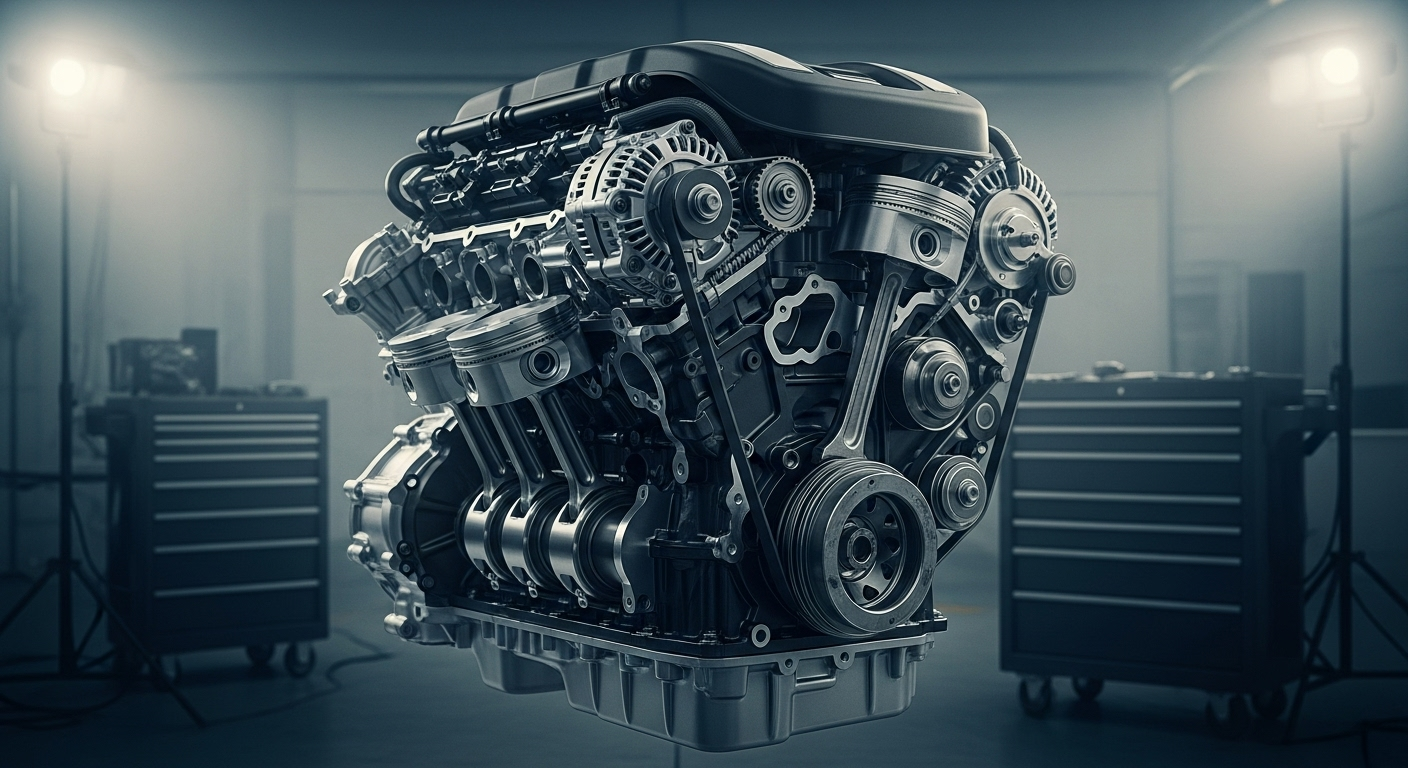

Thermoacoustic Effects in Engine Bay Applications

Thermoacoustic metamaterials address the dual challenge of heat management and sound control in automotive applications. These materials can simultaneously absorb sound waves and dissipate heat, making them particularly valuable in engine bay applications where both thermal and acoustic management are critical. The thermoacoustic properties allow these metamaterials to convert sound energy into heat energy, which is then efficiently dispersed, reducing both noise levels and component temperatures.

Manufacturing and Development Considerations

The manufacturing of automotive metamaterials requires precise engineering and advanced production techniques. Current development focuses on scalable manufacturing processes that can produce these complex structures cost-effectively for mass market vehicles. Additive manufacturing technologies, including 3D printing, enable the creation of intricate metamaterial geometries that would be impossible with traditional manufacturing methods. However, the integration of these materials into existing automotive production lines requires careful adaptation of assembly processes and quality control measures.

Suspension System Acoustic Integration

Modern suspension systems benefit significantly from metamaterial integration, particularly in managing road noise transmission. Metamaterial components within suspension assemblies can isolate vibrations before they reach the vehicle chassis, preventing road surface irregularities from creating cabin noise. These materials work in conjunction with traditional suspension components to provide both mechanical isolation and acoustic dampening, improving ride quality through multiple mechanisms simultaneously.

Aerodynamics and Sound Wave Management

Aerodynamic considerations in automotive design increasingly incorporate metamaterial solutions for managing wind noise and optimizing airflow around vehicles. Metamaterial surfaces can be designed to manipulate airflow patterns, reducing turbulence that creates unwanted noise while maintaining or improving aerodynamic efficiency. These materials can feature surface textures that guide airflow smoothly around vehicle contours, minimizing pressure differentials that typically generate wind noise at highway speeds.

The future of automotive sound engineering lies in the continued development and integration of these advanced materials, promising even quieter, more comfortable, and acoustically optimized vehicles for drivers and passengers worldwide.