Mobile Service Options: What to Expect from Onsite Pane Restoration

Mobile pane restoration brings many glass repairs to your driveway, workplace, or parking lot. This short overview highlights what technicians evaluate, the materials they use, and how mobile repairs can affect visibility, safety, and insurance documentation for vehicle panes and windshields.

Mobile Service Options: What to Expect from Onsite Pane Restoration

Mobile onsite pane restoration lets trained technicians evaluate and often repair vehicle glass without a trip to a shop. A technician arriving at your location will perform a visual inspection, assess whether a chip or crack can be repaired, and explain restoration options. Mobile repairs focus on restoring visibility and structural integrity while minimizing disruption, and they commonly interface with insurance processes. Understanding what the technician checks and the materials used helps set realistic expectations about outcomes, timing, and safety.

Windshield and pane inspection

A thorough inspection is the first step in mobile restoration. The technician checks windshield and pane condition, looking at chip size, crack length, location relative to sensors, and any edge damage that affects structural strength. Visibility is a primary consideration; even a small imperfection in the driver’s line of sight can change repair suitability. The inspection also identifies laminated versus tempered glass types, notes prior repairs, and documents damage for insurance and safety records. Clear photographic documentation is often created onsite for later reference.

How chips and cracks are assessed

When evaluating a chip or crack, technicians measure dimensions and assess depth and branching. Small bullseye chips or short star chips are commonly repairable using resin injection, while long cracks or extensive edge damage may require replacement. The assessment balances restoring optical clarity and preventing further spread. Technicians will explain whether restoration will improve visibility and structural integrity or only serve as a temporary fix. Decisions are based on standards for acceptable repairable damage and the particular characteristics of the pane.

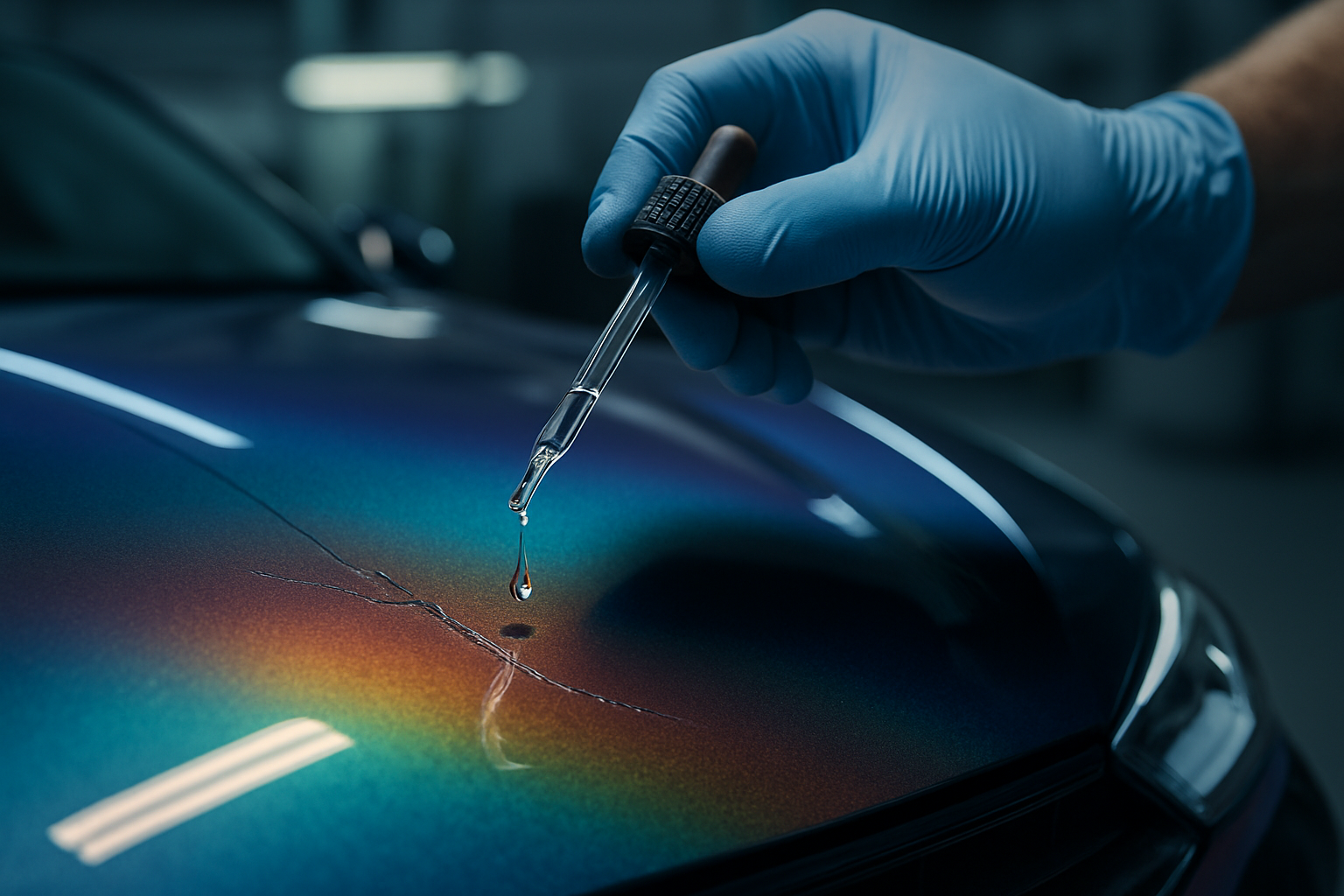

Resin, adhesive, and repair materials

Resin and adhesive quality matters for a successful repair. Mobile technicians use specialized resins designed for glass restoration; these fill voids, restore surface continuity, and reduce visibility of chips. For laminated windshields, adhesives bond the glass layers and the interlayer; technicians check that the resin is compatible with laminated construction. Curing is often performed with UV light to harden resin quickly. Proper material selection and application reduce optical distortion and help prevent crack propagation, maintaining a safer driving surface.

Differences in laminated vs. tempered glass

Laminated and tempered glass behave differently when damaged. Laminated panes, commonly used in windshields, contain an interlayer that helps hold fragments together and often allow for resin-based restoration. Tempered glass, used in many side and rear panes, shatters into small granular fragments and is typically not repairable after significant damage. Mobile technicians will identify glass type during inspection and recommend restoration approaches appropriate to laminated or tempered construction, always prioritizing safety and visibility.

Mobile service workflow and calibration needs

Onsite restoration follows a predictable workflow: inspection, documentation, preparation (cleaning and stabilizing the area), resin or adhesive application, curing, and final inspection. For vehicles with advanced driver assistance systems, calibration may be necessary after replacement rather than repair; technicians will note whether sensors, cameras, or heads-up displays could be affected. While many repairs do not require electronic recalibration, technicians must be aware of calibration needs and advise when a shop visit or specialist equipment is required to maintain safety features.

Insurance considerations and documentation

Insurance policies and claims can influence onsite restoration choices. Technicians commonly provide detailed inspection notes and photographs to support claims and to clarify whether repair or replacement is recommended. Coverage for mobile services varies by provider and policy; some insurers prioritize repair to restore visibility and limit costs, while others require specific documentation before approving replacement. Accurate documentation of visibility impairment, repair methods used, and any calibration recommendations helps align the onsite restoration with insurance requirements and safety standards.

Conclusion

Onsite pane restoration offers convenient options for addressing windshield and pane damage with a focus on restoring visibility and documenting safety implications. A clear inspection, appropriate use of resin and adhesives, and attention to glass type and calibration needs determine whether a chip or crack can be effectively restored. Detailed records provided by the technician support safety assessments and any necessary insurance follow-up.