On-the-job learning pathways for entry-level assembly workers

Entry-level assembly roles benefit from structured, hands-on learning that balances practical tasks with guided mentorship. This short overview highlights key on-the-job pathways—onboarding, focused training, ergonomic practices, quality inspection, and methods to support retention and upskilling in manufacturing settings.

On-the-job learning for entry-level assembly workers blends hands-on practice with structured guidance to build reliable skills quickly. Effective pathways emphasize clear task breakdowns, consistent feedback, and progressive responsibility so workers can perform reliably while learning how their role connects to quality, safety, and productivity goals. These approaches reduce errors and help teams integrate new workers into workflows without depending solely on classroom instruction.

How does onboarding shape assembly skills?

Onboarding sets the foundation for consistent assembly work by introducing processes, tools, and workplace expectations. A practical onboarding plan includes station walks, job aids that show step sequences, shadowing experienced assemblers, and short competency checks. Clear onboarding reduces early confusion and creates shared terminology for parts, inspection points, and safety steps, helping new hires move from observation to supervised practice more quickly while preserving product quality.

What training supports practical upskilling?

Training for entry-level assemblers should be modular and task-focused so workers can master small units of work before proceeding. Use short, repeatable exercises and checklists that emphasize critical skills such as fastening techniques, component alignment, and basic troubleshooting. Combine peer-led sessions, digital microlearning, and hands-on drills to support different learning styles. Upskilling pathways can include cross-training across stations and documented skill milestones that guide progression without relying on external certifications.

How does ergonomics affect productivity and safety?

Ergonomics training teaches body mechanics, workstation adjustment, and safe material handling to reduce fatigue and prevent injury. Simple interventions—proper tool positioning, adjustable fixtures, and scheduled micro-breaks—improve consistency and throughput by making tasks easier and less error-prone. Supervisors should model ergonomic best practices and incorporate ergonomic assessments into onboarding and regular safety briefings so workers learn to optimize posture and movements while maintaining production targets.

How are inspection and quality practices taught on the job?

On-the-job quality training pairs clear acceptance criteria with real examples of defects and rework processes. Practical exercises include guided inspections, use of measurement tools, and root-cause walkthroughs when defects occur. Embedding inspection checkpoints into assembly steps encourages early detection and corrective action, which preserves downstream workflow efficiency. Documented quality standards and quick reference guides help new workers recognize acceptable variation versus actionable defects.

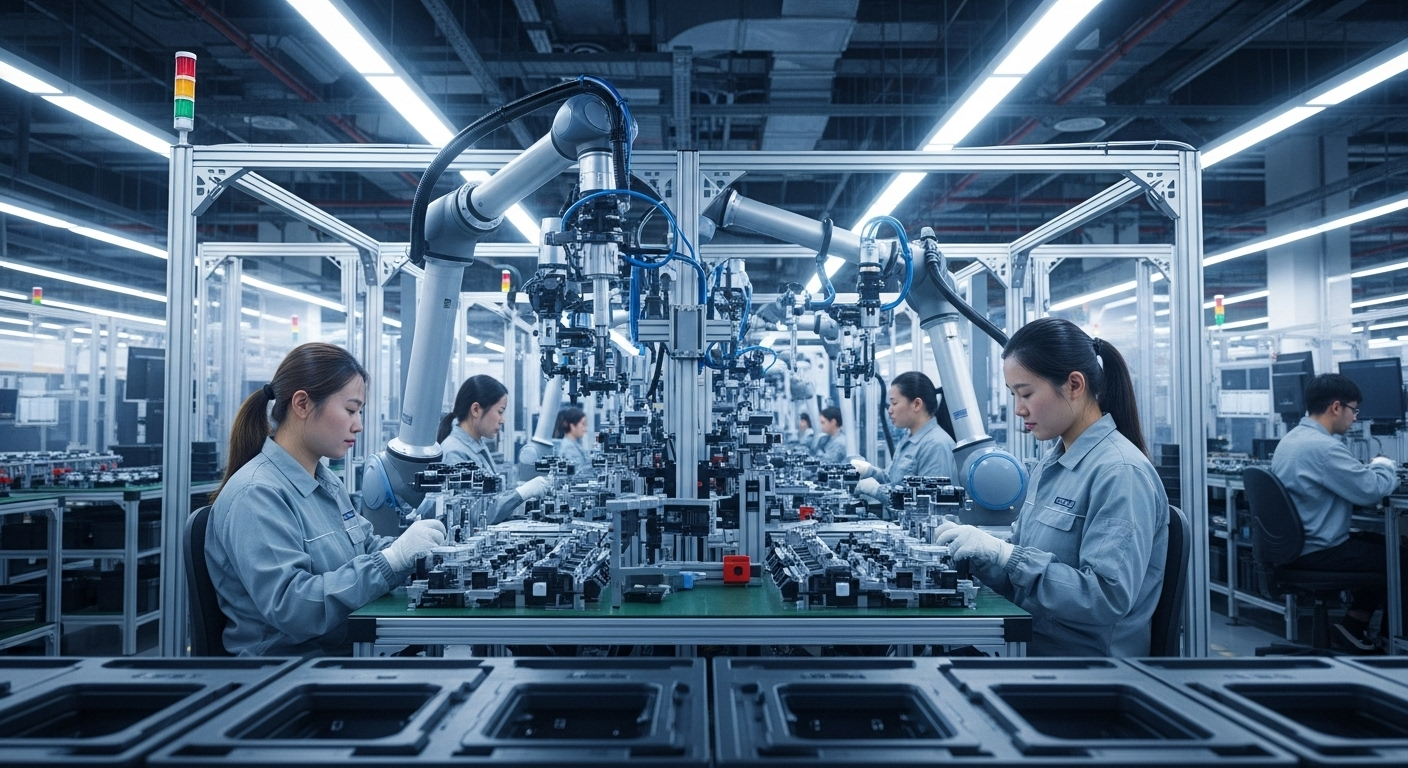

How can lean principles and automation be introduced to entry-level roles?

Introducing lean concepts and basic automation literacy early helps assemblers understand waste reduction and process flow. Start with simple lean tools—5S, standardized work, and visual controls—that make expectations transparent at the station level. When automation is present, provide hands-on familiarization with safety zones, basic interfaces, and how machines interact with manual tasks. Framing automation as an aid to consistency rather than a replacement supports worker buy-in and situational awareness.

What measures improve retention and career progression?

Retention improves when training pathways are visible and tied to measurable skill milestones. Mentorship programs, documented progression steps, and opportunities to rotate through related stations create variety and a sense of growth. Regular feedback sessions that focus on skill development—rather than only performance metrics—encourage workers to stay and advance. Pairing retention efforts with meaningful safety, ergonomics, and quality training reinforces competence and workplace confidence.

Conclusion

Practical on-the-job learning for entry-level assembly workers relies on structured onboarding, focused modular training, ergonomic practices, embedded inspection routines, and clear progression paths. When these elements are combined thoughtfully, assembly teams can maintain quality and safety while developing a resilient, adaptable workforce that meets production needs without overreliance on external training resources.