Shipping Container Homes: A Practical Green Living Guide

Discover how shipping container homes are reshaping sustainable housing with affordable, adaptable design. This guide covers environmental benefits, essential planning considerations like insulation and codes, creative customization options, cost breakdowns, and the construction steps needed to turn steel boxes into modern, eco-friendly residences. Ideal for readers curious about cost-effective, stylish alternative housing and sustainable building practices.

Shipping containers are being reinvented as comfortable, contemporary homes that blend sustainability with modern design. Once built for cargo transport, these steel modules now serve as durable building blocks for a new wave of eco-conscious architecture. Their strength, modularity, and potential for reuse make them an attractive option for anyone exploring affordable, green housing alternatives.

Benefits of Container Home Building

Reusing shipping containers reduces the demand for new construction materials and diverts large steel units from waste streams, lowering the project’s environmental footprint. Because containers are prefabricated, much of the work—such as cutting openings and reinforcing—can be completed off-site, shortening overall build schedules and reducing on-site labor costs.

Their standardized dimensions and structural integrity often mean less extensive foundations are required compared with conventional homes, which can translate to savings and make container dwellings viable on uneven or challenging terrain. The robust steel shells also offer resilience in harsh weather and can be stacked or combined to create multi-level layouts.

Essential Considerations for Container Houses

Steel conducts heat and cold efficiently, so effective thermal control is critical. Insulation choices—spray foam, rigid board, or insulated panels—affect interior comfort, moisture control, and usable square footage. Proper detailing around seams and openings is also necessary to prevent thermal bridging.

Ventilation must be planned to avoid condensation and ensure healthy indoor air quality. Mechanical ventilation, strategically placed vents, and moisture barriers can mitigate dampness, especially in humid climates. Corrosion protection, including cutting and welding treatments and appropriate coatings, helps extend the lifespan of the container structure.

Local building codes, permitting requirements, and zoning rules vary widely and can influence whether a container home is feasible in a given location. Before purchasing containers or finalizing plans, verify regulations on foundations, utility hookups, and habitability standards with local authorities.

Design and Customization Options

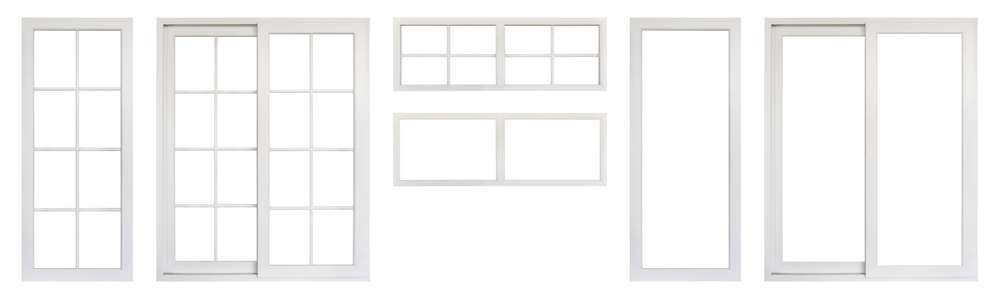

Container architecture is highly flexible, ranging from simple single-unit studios to elaborate multi-container residences. Designers commonly join multiple containers side-by-side or stack them to increase footprint and create dynamic interior volumes. Large openings for windows and doors can be cut into the steel, but these changes typically require reinforcing to maintain structural stability.

Green roofs and rooftop gardens are popular additions that enhance insulation, manage rainwater, and create outdoor living spaces. Integrating terraces, covered patios, or cantilevered elements expands usable space and connects indoor and outdoor living. Interior finishes can follow an industrial-chic aesthetic—showcasing exposed metal and beams—or be refined with drywall, hardwood floors, and high-end fixtures to deliver a more traditional, luxurious feel.

Sustainable features like solar panels, rainwater harvesting, and energy-efficient appliances are natural complements to container homes, amplifying their low-impact credentials and long-term cost savings.

Cost Analysis and Planning

Costs for container homes vary depending on the number of containers, level of finish, site conditions, and local labor rates. Below is a representative cost table to help with initial budgeting. These are illustrative ranges and will shift based on design complexity and location.

| Component | Basic Cost Range | Premium Cost Range |

|---|---|---|

| Single Container | $2,000 - $5,000 | $5,000 - $8,000 |

| Insulation & Interior Finish | $15,000 - $25,000 | $25,000 - $40,000 |

| Windows & Doors | $5,000 - $10,000 | $10,000 - $20,000 |

| Plumbing & Electrical | $10,000 - $20,000 | $20,000 - $35,000 |

| Foundation | $5,000 - $15,000 | $15,000 - $30,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

When budgeting, include costs for site preparation, transport of modified containers, permits, and contingencies for unforeseen site-specific challenges. Working with experienced contractors or architects familiar with container conversions can provide more accurate estimates and reduce the risk of costly revisions.

Construction and Installation Process

Typical workflow begins with selecting suitable containers—checking for structural soundness and contaminant-free interiors—and performing major modifications in a controlled workshop. This stage includes cutting openings for doors and windows, reinforcing altered sections, treating for corrosion, and installing initial insulation systems.

Completed modules are then delivered to the building site and set onto the prepared foundation. Fastening, sealing, and aligning containers precisely is crucial to ensure weatherproofing and structural performance. Once positioned, crews complete utility connections, interior framing and finishes, and exterior cladding or paint for additional protection and aesthetics.

Final commissioning involves testing electrical and plumbing systems, ensuring ventilation and insulation performance, and obtaining any required occupancy certifications. Throughout, communication between the homeowner, designer, and contractors helps keep the build on schedule and within budget.

Container homes are not without challenges—thermal bridging, moisture control, and local regulatory hurdles require careful attention—but with thoughtful planning they offer a compelling blend of sustainability, cost-efficiency, and contemporary style. For those seeking a distinctive, eco-friendly living solution, shipping container homes remain a versatile and increasingly mainstream option. Engaging knowledgeable professionals and researching local requirements early will increase the odds of a successful, durable, and comfortable outcome.