Simulation labs as tools for rapid operator proficiency

Simulation labs provide hands-on, low-risk environments where manufacturing operators can gain practical skills quickly. By combining virtual models, controlled equipment, and task-based practicum, these labs compress learning cycles for onboarding, maintenance, diagnostics, and routine automation tasks. They support competency-based curriculum design and offer measurable outcomes for workforce upskilling and reskilling.

Simulation labs offer controlled, repeatable settings where operators can build practical skills without exposing live production to risk. These spaces combine hands-on rigs, software emulators, and scenario-based practicum to accelerate learning curves for automation tasks, maintenance procedures, and diagnostic reasoning. Well-designed lab programs align with competency frameworks and provide measurable feedback that helps training teams refine curriculum and certify operator readiness.

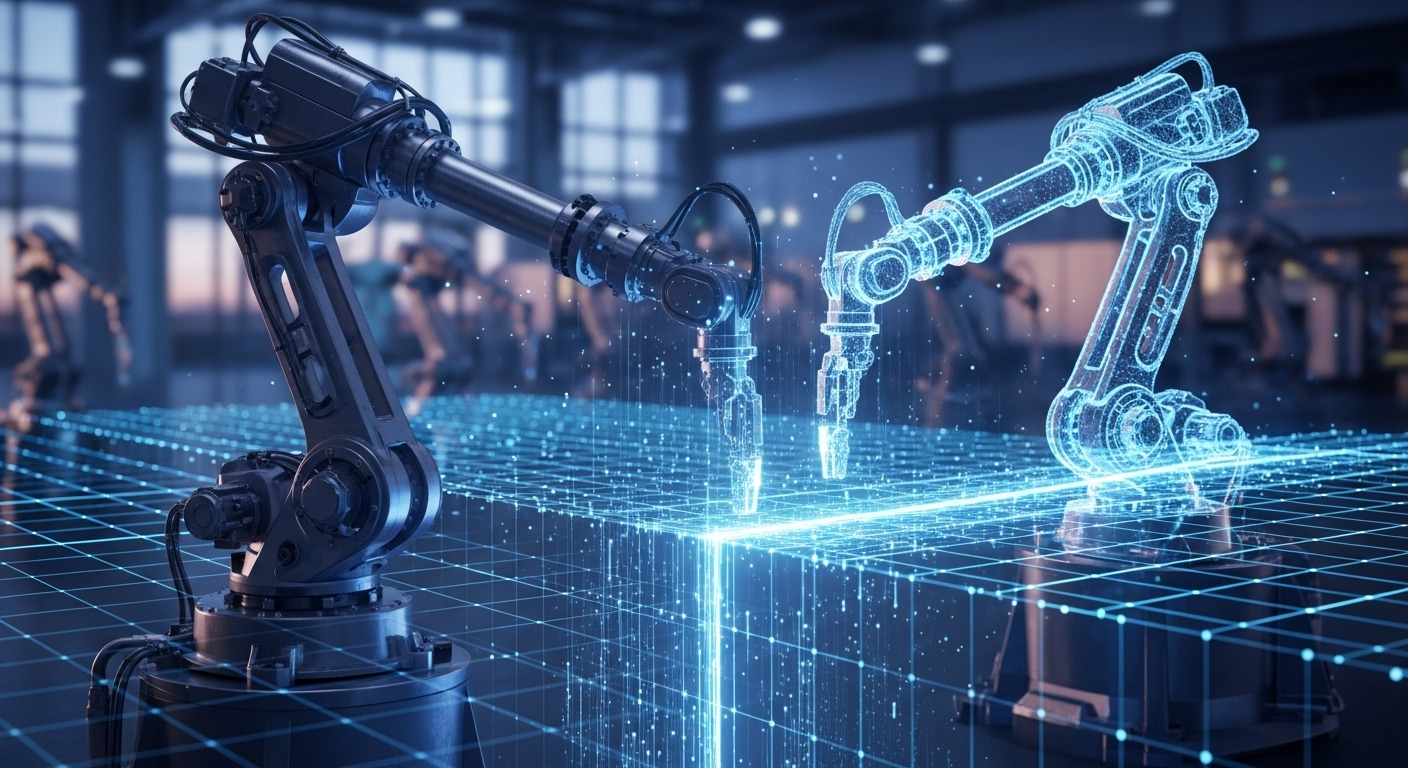

Simulation and automation

Simulation enables safe exposure to automated systems before operators interact with production equipment. Trainees practice PLC logic changes, HMI navigation, and robot sequencing within simulated cells that reproduce timing, interlocks, and sensor feedback. Repetition in a simulated environment reduces costly errors on the shop floor and shortens the time required for operators to demonstrate competency. Integrating realistic automation scenarios supports decision-making skills and teaches how to prioritize corrective actions when multiple faults occur.

Upskilling and reskilling pathways

Labs structure upskilling and reskilling with tiered modules that reflect career progression. Entry-level modules emphasize safe operation and basic diagnostics, while advanced modules focus on process optimization and predictive maintenance. For workers shifting roles due to increased automation, simulation practicum provides a low-stress route to mastering new tools and control philosophies. Objective performance metrics captured during sessions make it easier to document progress and identify specific skill gaps for targeted coaching.

Digital twin integration

Digital twin models increase the fidelity of simulation labs by mirroring real equipment behavior, process variability, and production data. Linking a digital twin to a lab setup lets trainees see cause-and-effect relationships between setpoint changes and output quality, or how intermittent sensor noise propagates through a control loop. This combination of physical and virtual testing supports diagnostics training and allows operators to validate corrective strategies against a model before applying them in production, reducing downtime risk.

Maintenance and onboarding practice

Simulation labs accelerate onboarding by letting new operators rehearse routine maintenance, lockout/tagout, and sensor calibration without interrupting operations. Maintenance-focused scenarios include common failure modes, component swaps, and systematic troubleshooting steps so trainees build procedural confidence. For onboarding, structured practicum that mirrors the shop floor’s standard operating procedures shortens ramp-up time and provides measurable checkpoints for supervisors to evaluate readiness for independent work.

Competency, curriculum, practicum

Effective lab programs map curriculum modules directly to competency statements and include recurring practicum for skill retention. Each training unit should have observable outcomes—such as successful diagnostic isolation, correct maintenance sequence, or safe machine restart—and an assessment rubric. Recording simulation runs enables instructors to review decision paths and highlight alternative approaches. Iterative curriculum updates informed by performance data keep training relevant as automation and process requirements evolve.

Certification, diagnostics, operators

Simulation-based testing supports objective certification by standardizing assessment conditions and performance metrics. Metrics can include time-to-diagnosis, accuracy of fault isolation, adherence to safety protocols, and correct parameter adjustments. These measurable outcomes make certification defensible and provide employers with documented evidence of an operator’s capability. Additionally, focused diagnostics practicum improves the workforce’s ability to reduce mean time to repair and maintain consistent product quality.

Conclusion Simulation labs are practical tools for building operator proficiency across automation, maintenance, and diagnostics. By combining realistic simulations, digital twin models, and competency-driven curriculum, organizations can shorten onboarding timelines, enable upskilling and reskilling, and create verifiable certification pathways. Emphasizing practicum, recorded assessments, and data-driven curriculum adjustments helps ensure the workforce maintains competence as equipment and processes change, while minimizing risks to live production systems.