Soldering vs pre-built: a guide to assembling input hardware

Compare soldering and pre-built approaches to assembling input hardware, focusing on practical differences like customization, durability, maintenance, and portability. This preview outlines what to consider when choosing between DIY builds and ready-made units.

Choosing whether to solder a custom input device or buy a pre-built model affects many practical factors: mechanical feel, long-term maintenance, and how much you can tailor the device to personal needs. This guide explains trade-offs around switches, keycaps, layouts, and connectivity so you can match an assembly approach to priorities like ergonomics, latency, acoustics, and portability.

Mechanical switches and hotswap options

Mechanical switches define the tactile and audible response of an input device. Pre-built models often ship with a fixed set of switches chosen for a balance of feel and cost, while DIY builds let you select switches that match typing style. Hotswap PCBs provide a middle ground: they allow switch swapping without soldering, enabling iterative customization of switches and reducing maintenance time. When evaluating options consider actuation force, travel, and whether you want linear, tactile, or clicky switches—these attributes affect ergonomics and acoustics directly.

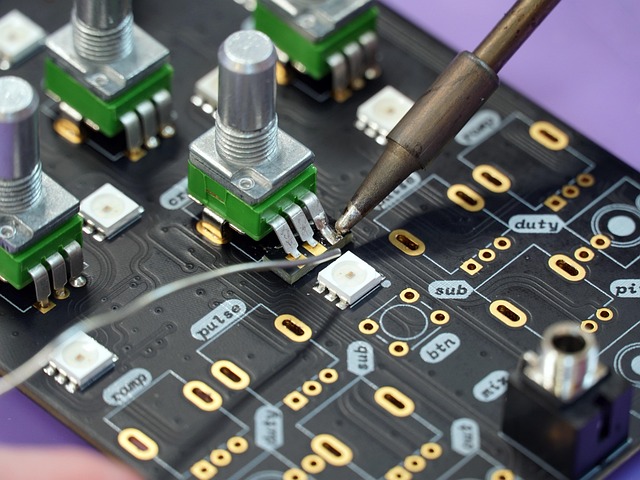

Soldering: durability and maintenance

Soldered builds require a steady hand and basic tools, but they can offer greater long-term durability when properly assembled. Permanent solder joints secure switches and components, reducing the chance of intermittent connections in high-use environments. Maintenance for soldered keyboards often means desoldering to replace parts, which is more time-consuming than hotswap swaps. Regular care—cleaning, stabilizer tuning, and occasional resoldering—keeps a soldered board reliable, though repairs may need local services or more complex DIY skills.

Keycaps, acoustics, and customization

Keycaps and case materials shape acoustics, feel, and aesthetics. Pre-built units tend to include stock keycaps and default profiles, while assembled builds let you choose profiles, materials (ABS, PBT), and legends. Customization can also extend to backlighting options and stabilizer mods that influence sound. Acoustic preferences vary: some users favor a muted, low-profile sound for shared spaces, others prefer a sharper, louder click. Custom builds allow targeted acoustic tuning via foam, dampening, or different keycap thicknesses to meet those needs.

Layouts, ergonomics, and portability

Layout choices—tenkeyless, 60%, split, or ortholinear—affect ergonomics and portability. Pre-built keyboards cover common formats and are convenient for users who want a plug-and-play solution. DIY assembly opens up less common layouts and ergonomic designs that may reduce strain for specific workflows. Portability considerations include weight, case size, and whether a board is wireless; smaller layouts and lightweight materials improve transportability but can alter typing comfort and key placement familiarity.

Wired vs wireless: latency and backlighting

Wired connections generally offer lower latency and consistent power for features like backlighting; they are often preferred for latency-sensitive tasks. Wireless options provide portability and cable-free setups but require battery management and can introduce variable latency depending on protocol and environment. Many modern wireless implementations approach wired responsiveness for everyday use, though competitive or professional scenarios may still favor wired setups. Backlighting choices—RGB, single-color, or none—impact power consumption and firmware complexity.

Assembly time, tools, and long-term care

Time investment, required tools, and maintenance needs differ significantly between soldered and pre-built paths. Pre-built units need minimal setup beyond keycap changes or firmware tweaks. Soldered builds demand soldering irons, flux, and sometimes a desoldering station for future repairs; hotswap boards reduce this barrier. Long-term care includes cleaning, stabilizer lubrication, firmware updates, and occasional part replacement. Durability, latency, and user satisfaction depend on both initial assembly quality and consistent maintenance practices over time.

Conclusion

Soldering offers a higher degree of permanence and potential durability at the cost of greater setup and repair complexity, while pre-built and hotswap options prioritize convenience and ease of customization. Consider how much you value customization, acoustics, portability, and latency when choosing between soldered, hotswap, or pre-built approaches. Matching assembly method to your daily needs and maintenance willingness leads to a more satisfying input hardware experience.