Standards and Protocols Improving Device Interoperability

Interoperability across modern devices depends on widely adopted standards and clear protocols that bridge component diversity, software stacks, and manufacturing practices. By aligning hardware, firmware, and communication layers, industries can reduce fragmentation, accelerate development, and improve device longevity while supporting sustainability and broader system compatibility.

How do standards affect hardware and semiconductors?

Standards create predictable interfaces and electrical characteristics that allow components from different vendors to work together reliably. For hardware and semiconductors, this means defined pinouts, signal levels, and form factors that reduce custom engineering and speed time to market. Consistent standards also help testing and compliance regimes, making it easier to validate thermal behavior and performance across designs. In supplychain terms, adherence to standards simplifies sourcing and assembly because manufacturers can accept interchangeable parts rather than redesigning boards or enclosures for each supplier variation.

What role does firmware play in interoperability?

Firmware implements the device logic that negotiates protocols, handles sensors, and manages connectivity. Well-documented firmware APIs and firmware update mechanisms enable devices to speak common languages and receive upgrades that preserve compatibility. Standardized bootloaders, update formats, and security models reduce fragmentation, limit integration risk, and enable repairability through software fixes. For edgeai and other compute-intensive functions, firmware bridges semiconductors and higher-level software, ensuring that models, drivers, and runtime environments can interoperate across different hardware platforms.

How do sensors and connectivity standards align?

Sensor interfaces rely on common electrical and data protocols so readings can be aggregated and interpreted uniformly. Standards like defined bus protocols, data serialization formats, and time synchronization methods allow disparate sensors to feed a shared system without per-sensor custom glue. Connectivity standards — whether wired or wireless — set expectations for latency, bandwidth, and security, which in turn inform performance and thermal design. When sensors and connectivity follow common specs, developers can prototype faster and build interoperability into products from the outset rather than retrofitting adapters later.

How does modularity support upgradability and repairability?

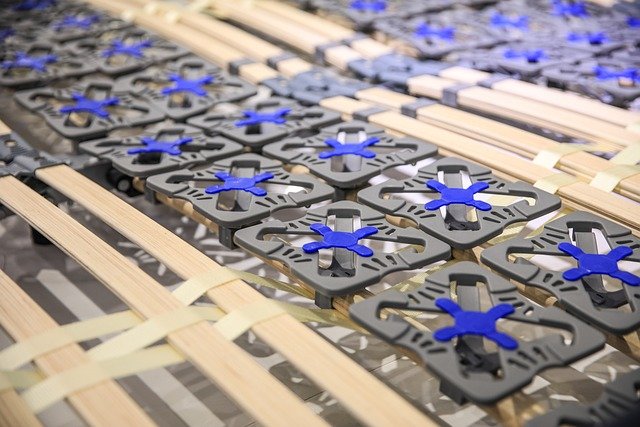

Modularity is a practical design pattern that standards enable: standard mechanical interfaces, connector types, and modular software components let manufacturers and end users replace or upgrade parts without replacing entire systems. This approach promotes upgradability, repairability, and recyclability by design, reducing waste and extending product life. Standards for module dimensions, power delivery, and communication protocols also permit third-party expansions and encourage an ecosystem of compatible modules, which helps sustainability goals and provides clearer paths for maintenance and refurbishment.

How do performance and thermal standards influence design?

Performance metrics and thermal guidelines provide targets for designers and suppliers, creating shared expectations for how devices behave under load. Established benchmarks and thermal testing standards guide choices in semiconductors, heatsinking, and enclosure design to ensure reliability and predictable performance. During prototyping and assembly, compliance with these standards shortens verification cycles because engineers can measure against known criteria. Clear performance and thermal specs also inform supplychain decisions, helping choose components that meet both computational needs and thermal constraints while avoiding late-stage redesigns.

How do supplychain, prototyping, and edgeAI rely on interoperability?

Interoperability reduces complexity across the supplychain by defining interfaces that multiple suppliers can meet, which simplifies procurement, assembly, and testing. In prototyping, compatible boards, connectors, and standard drivers accelerate iterations and validation, lowering the barrier to experiment with edgeai and other advanced capabilities. For edgeai specifically, standards in model packaging, runtime APIs, and data formats ensure models move smoothly from development to deployment, across different hardware accelerators and semiconductors. Overall, a standards-driven ecosystem improves predictability and resilience in manufacturing and integration.

Interoperability is less a single technology than a framework of coordinated standards spanning hardware, firmware, sensors, connectivity, and manufacturing practices. When standards are clear and widely adopted, they ease prototyping, support modularity and repairability, guide performance and thermal design, and strengthen supplychain efficiency. That coordinated approach helps products achieve longer lifetimes, better sustainability outcomes, and more reliable operation across diverse deployment environments.