Sustainable manufacturing practices for assistive devices

Sustainable manufacturing practices can reduce environmental impact while improving outcomes for assistive devices such as prostheses and orthotics. This article reviews materials choices, design strategies, digital tools, and accessibility considerations that support durable, comfortable, and biocompatible solutions across diverse rehabilitation and mobility needs.

Mobility and rehabilitation in manufacturing

Designing assistive devices with sustainability in mind starts by aligning manufacturing goals with long-term mobility and rehabilitation outcomes. Sustainable processes emphasize durability and repairability so devices remain effective through prolonged use and changing patient needs. Incorporating modular designs and standardized attachment interfaces can simplify maintenance, reduce waste, and extend device life. Manufacturing choices should consider the full lifecycle impact on users’ mobility, including how replacement parts, adjustments for alignment, and upgrades for sensors or electronics will be supported without requiring complete device replacement.

Materials and biocompatibility choices

Selecting materials that balance environmental footprint with biocompatibility is central to responsible device manufacturing. Recycled or bio-based polymers can lower emissions, but they must meet biocompatibility and wear-resistance requirements for skin contact and load-bearing applications. Metals and composites should be sourced with attention to recyclability and supply chain transparency. Material testing for corrosion, toxicity, and long-term interaction with soft tissues is essential; choosing materials that support safe, comfortable skin contact and predictable mechanical performance reduces waste from returns and reworks.

Durability, fit, alignment, and comfort

Durability directly influences sustainability: longer-lasting components reduce replacement frequency and resource use. Proper fit and alignment are also sustainability levers because well-fitted limbs and orthotics improve user comfort and reduce the need for corrective remanufacturing. Precision manufacturing techniques such as CNC machining, additive manufacturing, and careful quality control help achieve repeatable alignment and consistent fit. Ergonomic design that prioritizes comfort and load distribution reduces localized wear and improves adherence to rehabilitation plans, contributing to better long-term outcomes for mobility.

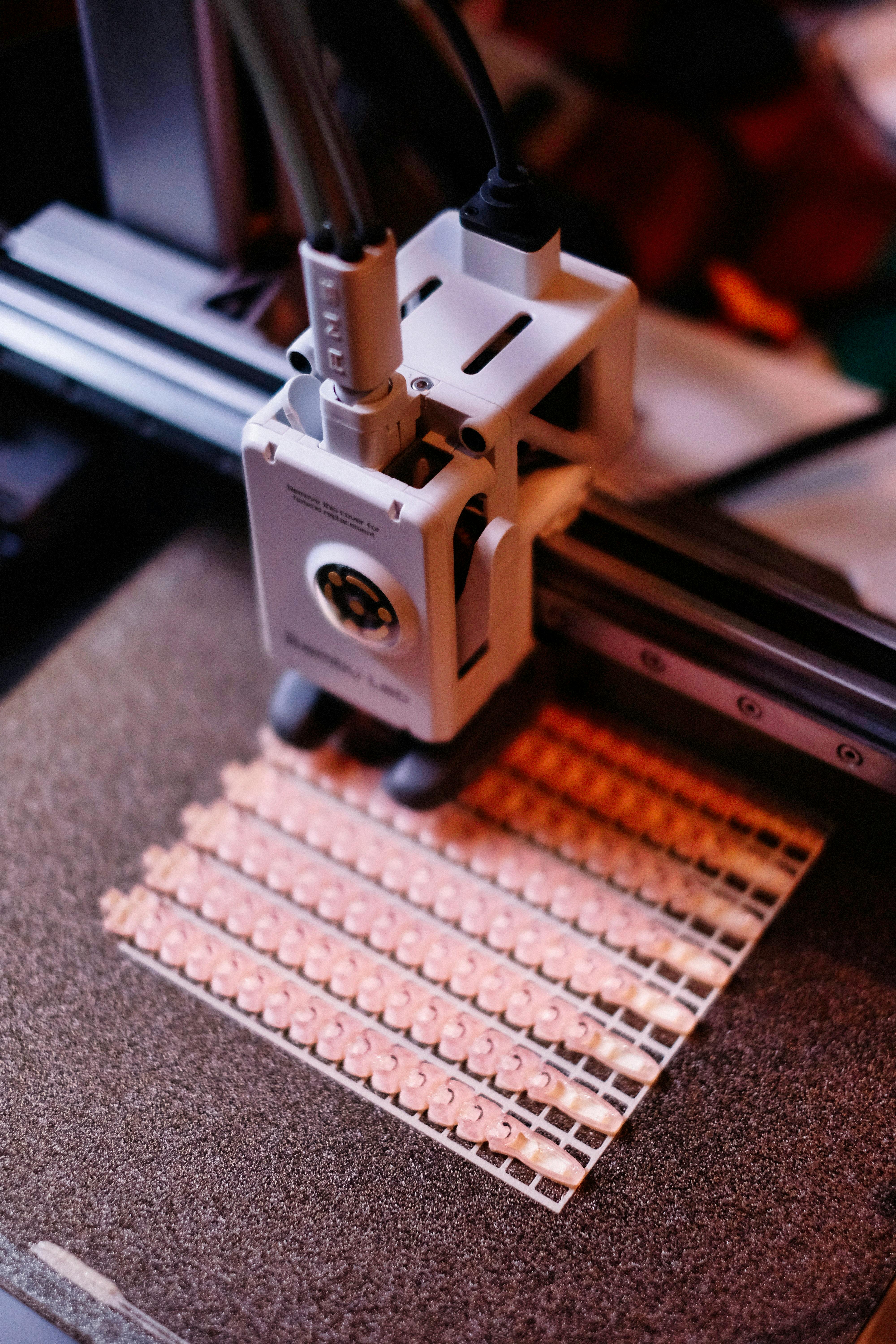

Customization, limbs, and orthotics

Customization reduces unnecessary inventory and can enhance device effectiveness. Digital workflows that combine 3D scanning, parametric modeling, and additive manufacturing enable tailored sockets, liners, and orthotic components for individual limbs while minimizing material waste. On-demand production of customized parts shortens lead times and lowers storage needs. Careful design for disassembly allows core components to be retained while worn or patient-specific elements are replaced, which supports sustainability and ensures ongoing fit as a user’s rehabilitation progresses.

Sensors, telehealth, and digital integration

Integrating sensors and telehealth capabilities can improve clinical outcomes while influencing sustainability. Remote monitoring can reduce in-person visits and the associated travel emissions, and sensors can provide data that informs targeted adjustments rather than full device replacements. Digital calibration and firmware updates extend device functionality without hardware changes. However, electronic components require responsible sourcing and end-of-life planning: manufacturers should design for repairability, support battery recycling, and plan take-back programs to manage electronic waste responsibly.

Accessibility and sustainable manufacturing

Sustainable manufacturing must also enhance accessibility. Local services and regional manufacturing hubs can shorten supply chains, reduce delivery emissions, and improve responsiveness to fitting and alignment needs in your area. Training local technicians and offering digital design files for distributed production can increase availability while maintaining quality standards. Affordability strategies that prioritize lifecycle cost and reparability over cheap, single-use parts improve long-term access to effective rehabilitation devices and reduce environmental burden.

This article is for informational purposes only and should not be considered medical advice. Please consult a qualified healthcare professional for personalized guidance and treatment.

Sustainable manufacturing for assistive devices requires a systems approach: thoughtful material selection, durable and comfortable design, digital customization, and responsible handling of electronics and end-of-life materials. By prioritizing fit, alignment, and user-centered design alongside environmental considerations, manufacturers and clinicians can support mobility and rehabilitation outcomes that are both effective and resource-efficient.