Technology and mechanism differences in modern retractable roofs

Modern retractable roofs combine materials science, mechanical engineering and vehicle packaging to offer variable exposure without sacrificing everyday usability. This overview outlines how fabric softtops, folding hardtops and sliding openroof systems differ in construction, operation and long-term care, and how those differences affect safety, weatherproofing, maintenance and ownership decisions.

Retractable roof systems vary widely, from simple manual softtop designs to complex electro-hydraulic folding hardtops and sliding openroof panels. Each approach balances trade-offs in weight, packaging, noise, and durability. Understanding the underlying materials and mechanics helps owners anticipate inspection needs, roofcare routines, and the practical effects on aerodynamics, insurance considerations and resale value. This article breaks down the main technologies and explains how they influence ongoing maintenance and ownership responsibilities.

How do softtop and materials differ?

Fabric softtops typically use layered textiles such as acrylic-coated cloth, multi-layered PVC or canvas blends combined with supporting bows and seals. These materials are selected for flexibility, UV protection and water resistance, but they can age differently: fabrics are prone to fading, stitching wear and seam degradation, while vinyl options may become brittle. Hardtop panels use stamped steel, aluminum or composite materials that resist puncture and offer different thermal behavior. Material choice directly affects roofcare tasks like cleaning, conditioning, and the frequency of professional inspection to prevent leaks and preserve weatherproofing.

What mechanics power retractable systems?

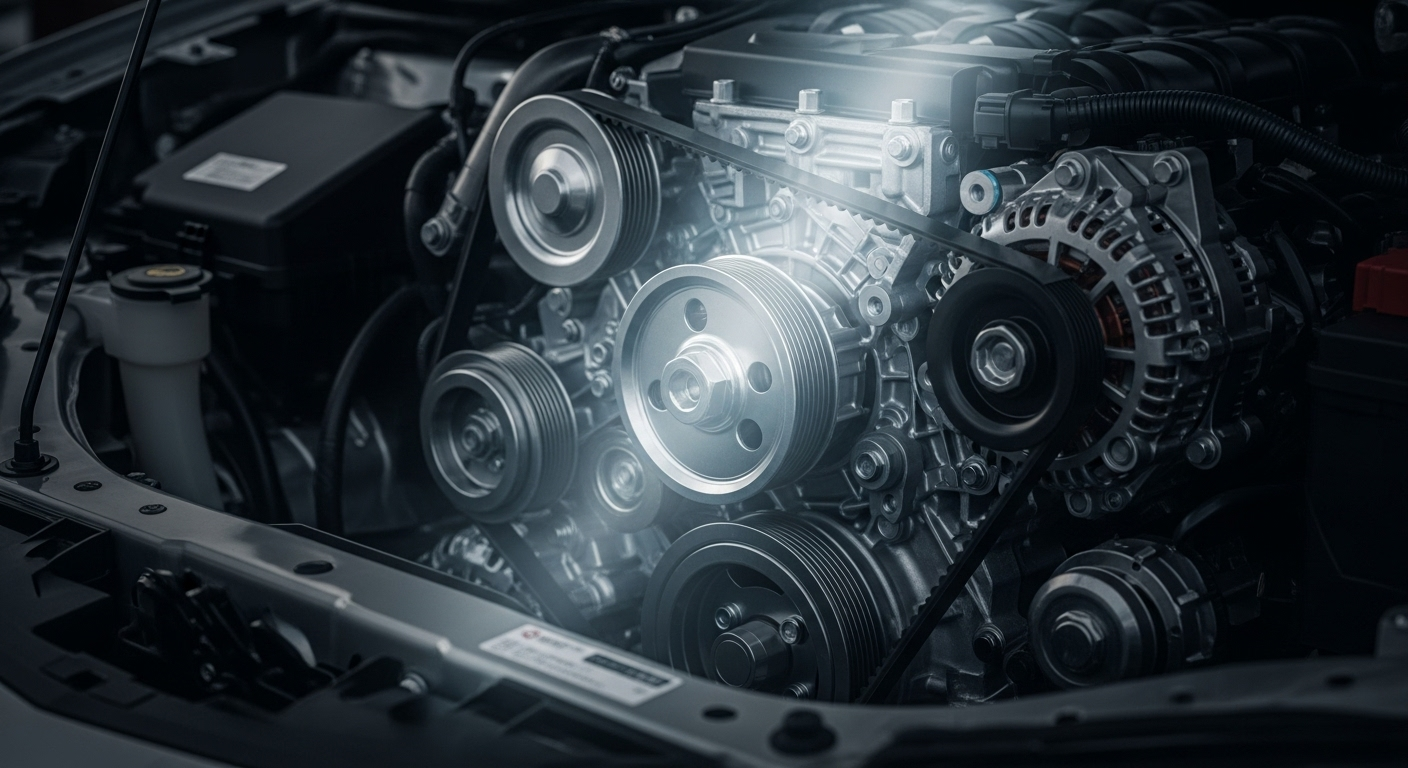

Mechanisms range from simple manual latches and straps on basic softtops to electrically actuated motors, hydraulic pumps and synchronized linkages on sophisticated folding hardtops. Motor-driven systems rely on control modules and sensors to coordinate multiple moving panels, hinges and locking points, while some sliding openroof systems use rails and worm gears for quiet, precise motion. Mechanical complexity increases potential failure modes: actuators, cables, and switches may fail or require calibration. Familiarity with a system’s mechanics helps owners understand probable repair points and informs regular inspection schedules to detect wear before it causes misalignment or leaks.

How do aerodynamics and safety interact?

Roof geometry and sealing affect airflow and cabin pressure at speed. Openroof and softtop configurations change aerodynamic drag and can introduce buffeting that influences noise and comfort. Hardtops usually provide more consistent airflow management and structural support in rollovers, while properly reinforced softtops can meet safety standards but may rely more on integrated roll bars or reinforced windshield frames. Safety considerations also include the integrity of latching mechanisms and visibility when the roof is stowed. Regular inspection of locks, hinges and seals is part of maintaining safe operation and ensuring that any insurance requirements regarding roof condition are met.

What inspection, maintenance, and roofcare are recommended?

Routine checks should cover seals, drainage channels, fabric condition, and the operation of motors and linkages. For softtops, cleaning with compatible products and applying UV protection treatments can extend material life; avoid abrasive cleaners that accelerate wear. For mechanical systems, periodic lubrication of hinges and rail tracks, and verification of electrical connectors reduces the chance of failures. Annual or biannual professional inspections catch hidden problems such as blocked drains, worn actuators or compromised seals. Proper maintenance preserves weatherproofing, reduces the likelihood of costly repairs, and supports better long-term ownership outcomes.

How do weatherproofing, UV protection, insurance, and resale factor in?

Weatherproofing depends on material and seal integrity: compromised seams or worn seals can allow moisture ingress, leading to interior damage and higher insurance claims. UV protection treatments for fabrics reduce fading and embrittlement, preserving both appearance and waterproofing. Insurers may request documentation of regular maintenance for certain coverages, and a well-documented inspection and roofcare history can support resale value. Buyers often weigh the condition of the retractable roof heavily; a mechanically sound, weatherproof system with recent service records is likely to be viewed more favorably than one with visible wear or unresolved leaks.

Conclusion

Different retractable roof technologies present distinct trade-offs in mechanics, materials and maintenance. Softtops emphasize packaging and light weight but need attentive fabric care and regular inspections, while folding hardtops provide rigid protection at the cost of greater mechanical complexity. Sliding openroof systems offer a middle ground in terms of simplicity and performance. Understanding these differences helps with realistic expectations about roofcare, weatherproofing, safety implications, and how maintenance influences insurance and resale considerations.